Model Driven Development and Decision Support | 2013-2022

- Post by: Tobias Larsson

- 31st August 2022

- 73 Comments

Model Driven Development and Decision Support | 2013-

Building an international research profile in the area of Sustainable Product-Service System Innovation at Blekinge Institute of Technology

Kick-down week in São Paulo

São Paulo, Brazil - The international project team from this year's Volvo CE Sugar project experienced a week of intensive…

Launching a new chapter with Sugar

Having run 11 projects in ME310, the PDRL Global Engineering student project will explore innovation opportunities in South America and…

ME310 2023 kicking off

BTH is back again this year, joining forces with Stanford Mechanical Engineering and the Volvo Group for a final-year ME310…

ME310 Convergence week på Stanford

BTHs team i Stanfordprojektet ME310 är precis hemkomna från ”Convergence Week” på Stanford University, där man tillsammans har jobbat med…

Produktutvecklingsforskningen med på IVA’s 100-lista 2020!

Professor Tobias Larsson och teamet kring forskningsprofilen Model Driven Development and Decision Support är med på Kungl Ingenjörsvetenskapsakademien, IVA's 100-lista…

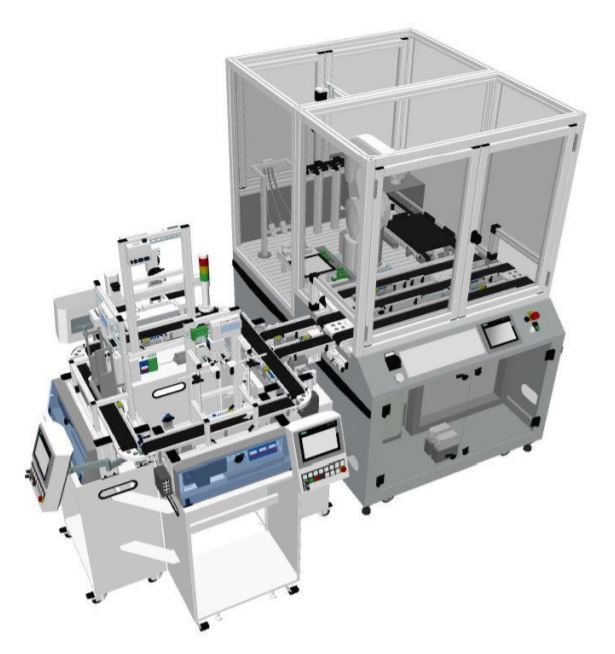

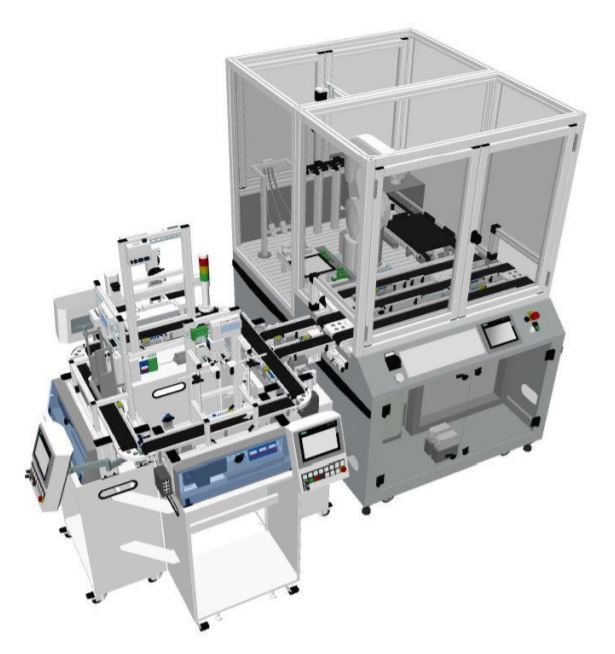

Industry 4.0 Cyber Physical Factory!

With the ongoing transformation of industrial product development and production, and especially how Internet of Things (IoT), smart factories, cyber-physical…

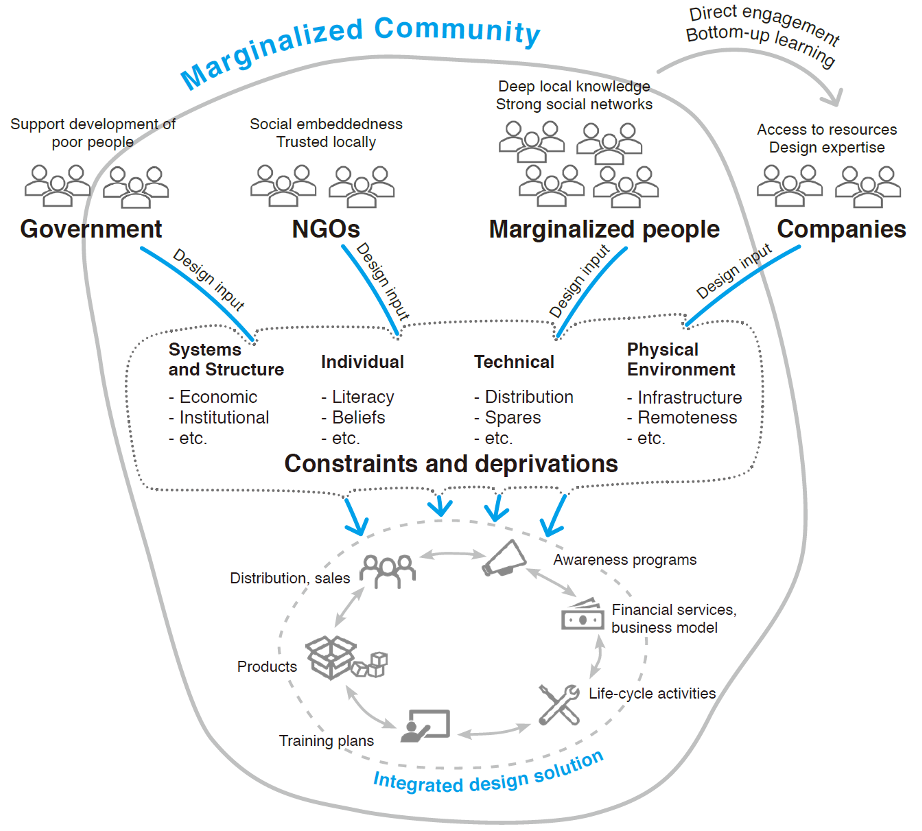

PSS Design for the World’s Large Market

Businesses are recognising and pursuing the opportunity to design appropriate products and services to serve the market known as the…

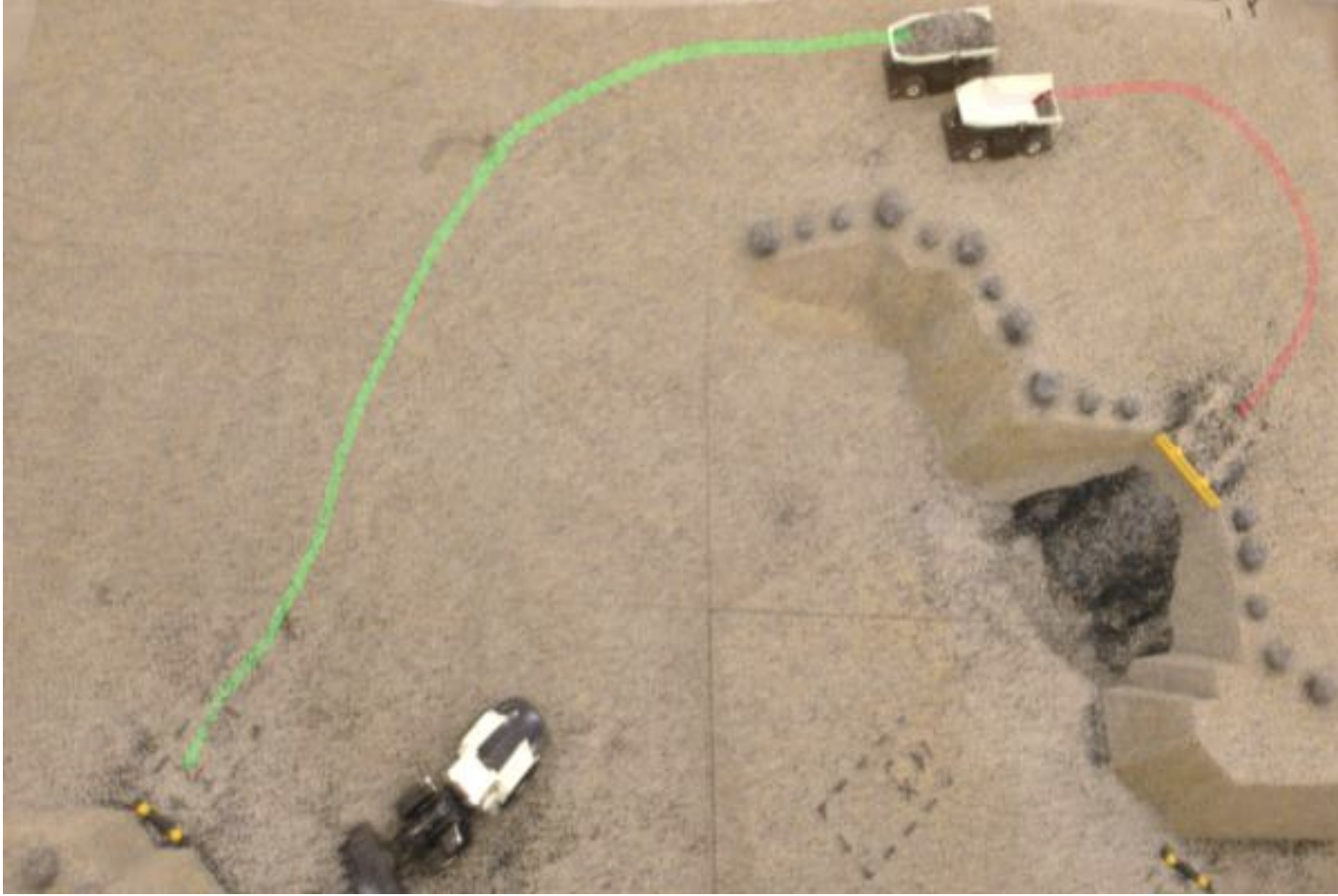

VCE Electric Site Scaled Demo

Volvo CE is making steady progress towards realizing their sustainable construction vehicle goals of zero accidents, zero emissions, zero unplanned…

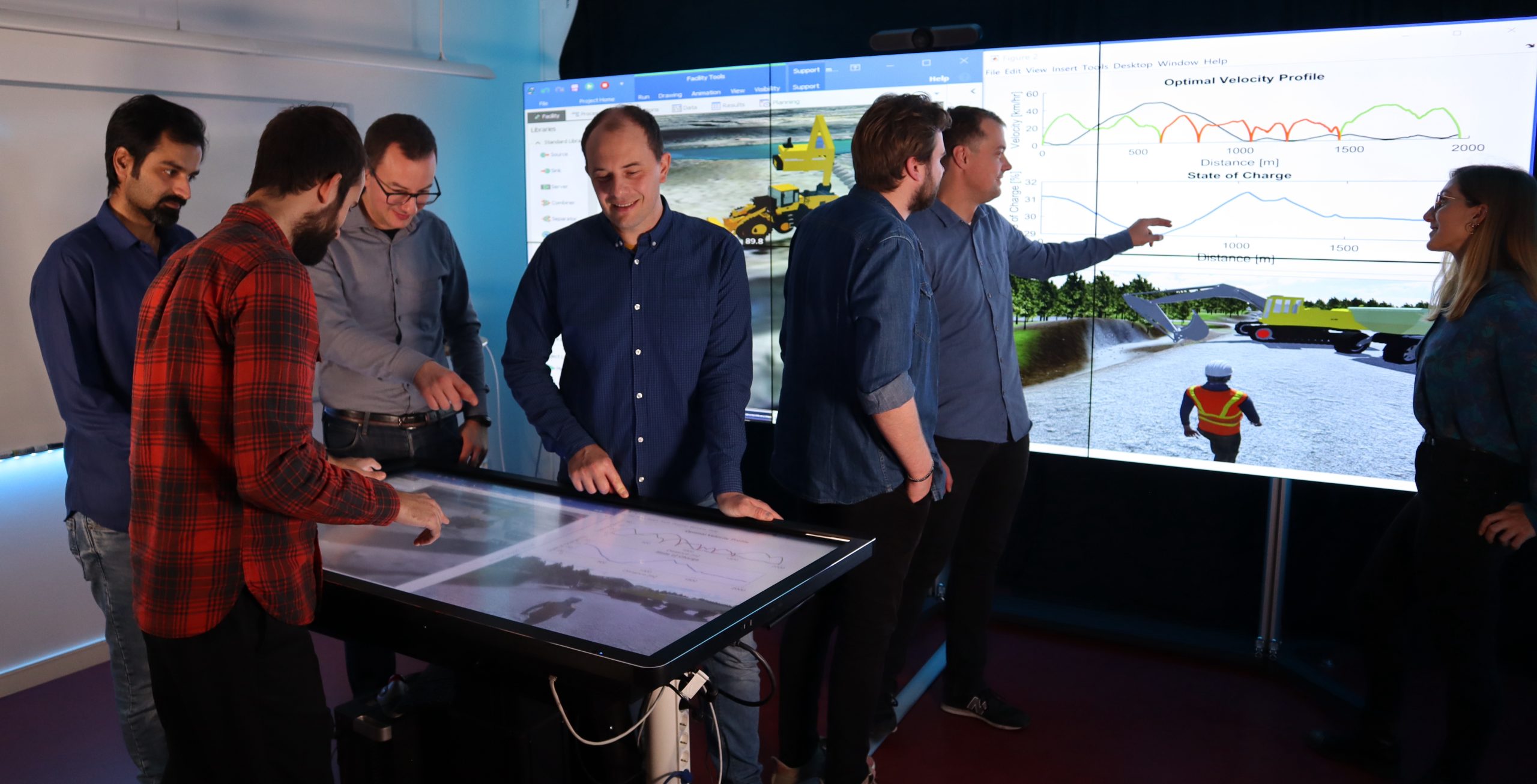

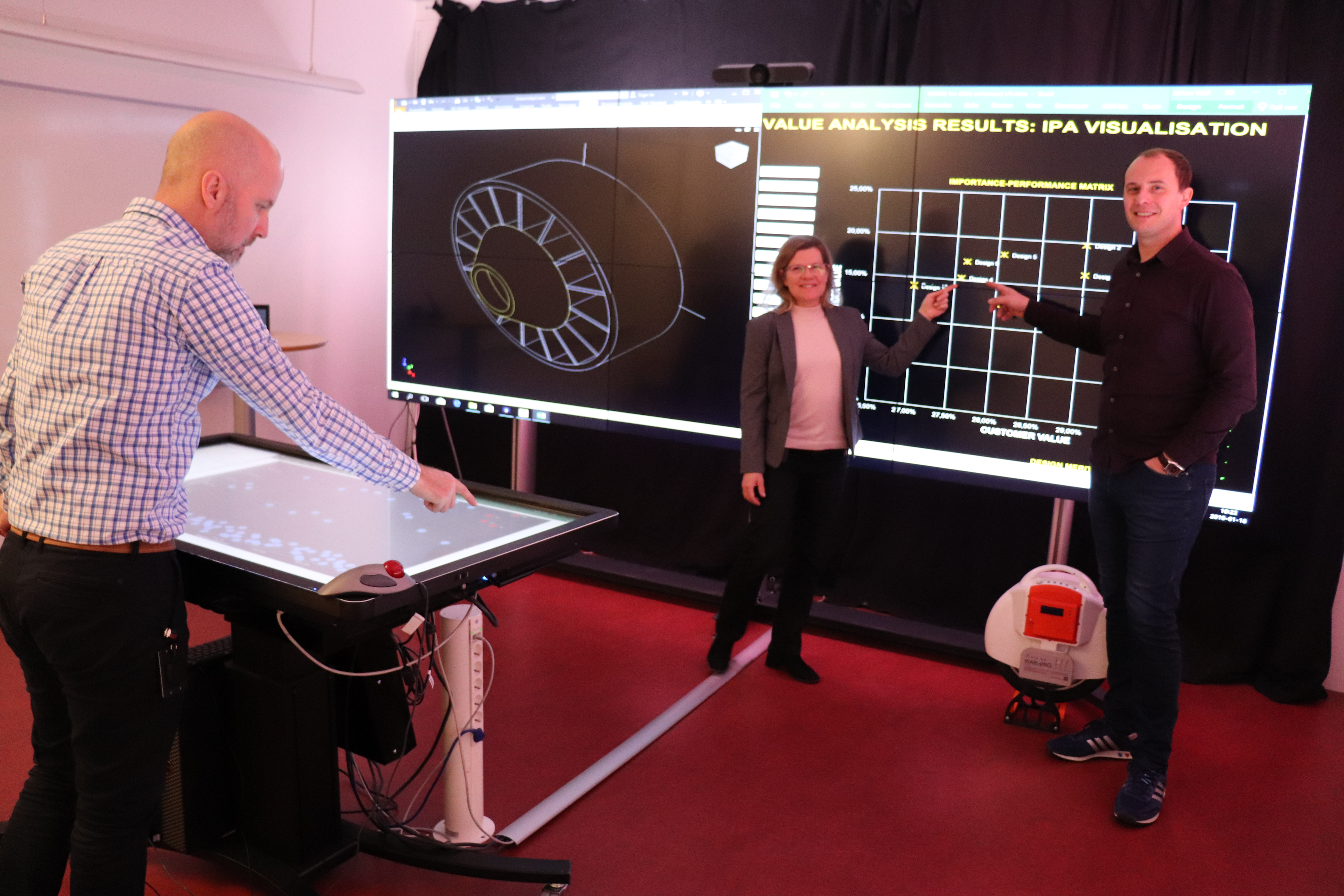

Model Driven Decision Arena – MDDA

One success factor in engineering design is the ability to make effective and risk-managed decisions in a timely manner. Rarely…

Let the machines talk! Towards data-driven product development

Leonardo da Vinci is remembered in history as a “universal genius”, he was an artist, a scientist, a mathematician and an…

Value-Driven Design – sustainable products and service innovation with value in focus

In 1903, Charlie Taylor was given the task to design a completely new engine able to propel the first ever…

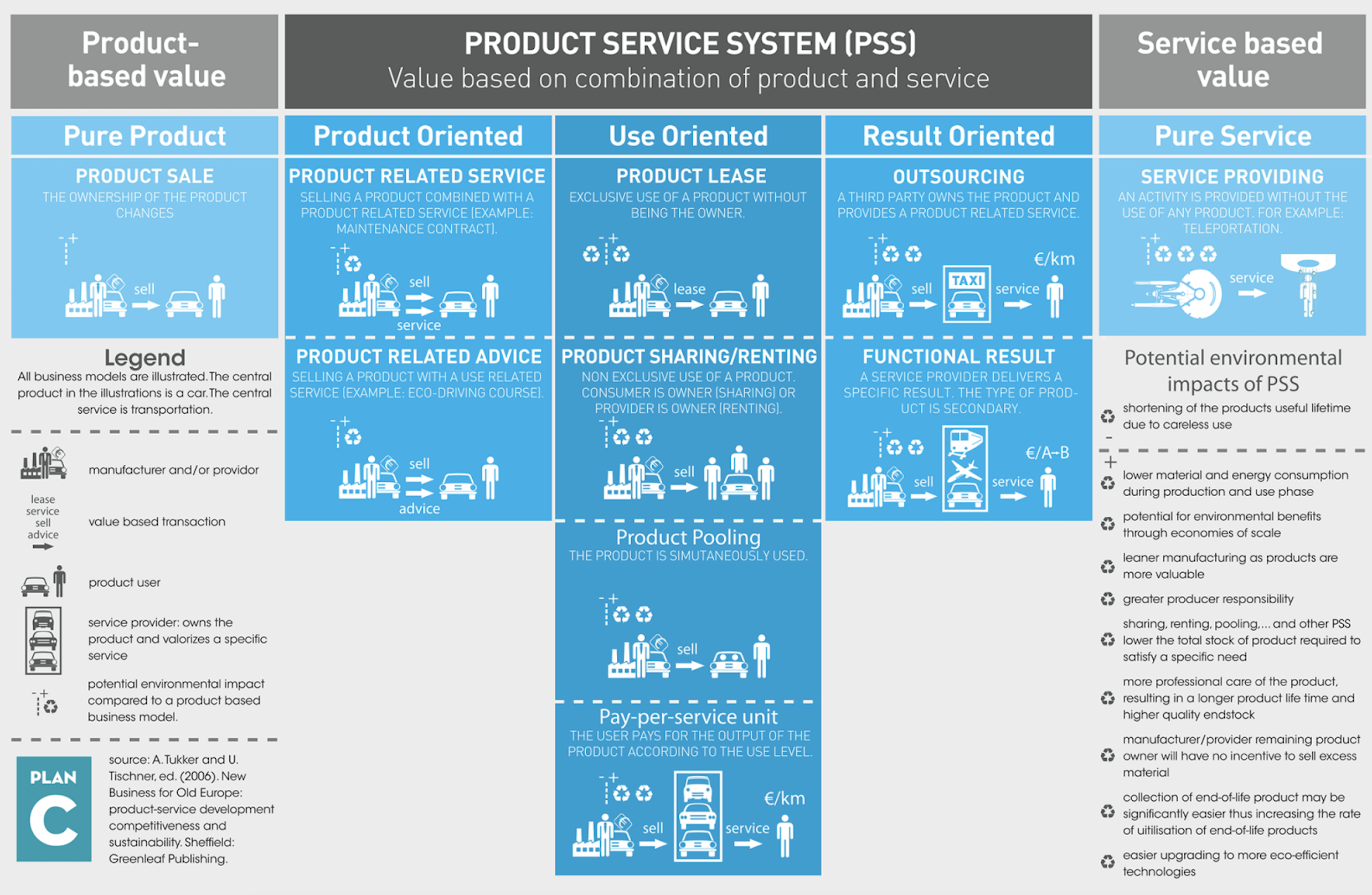

Product-Service Systems Innovation?

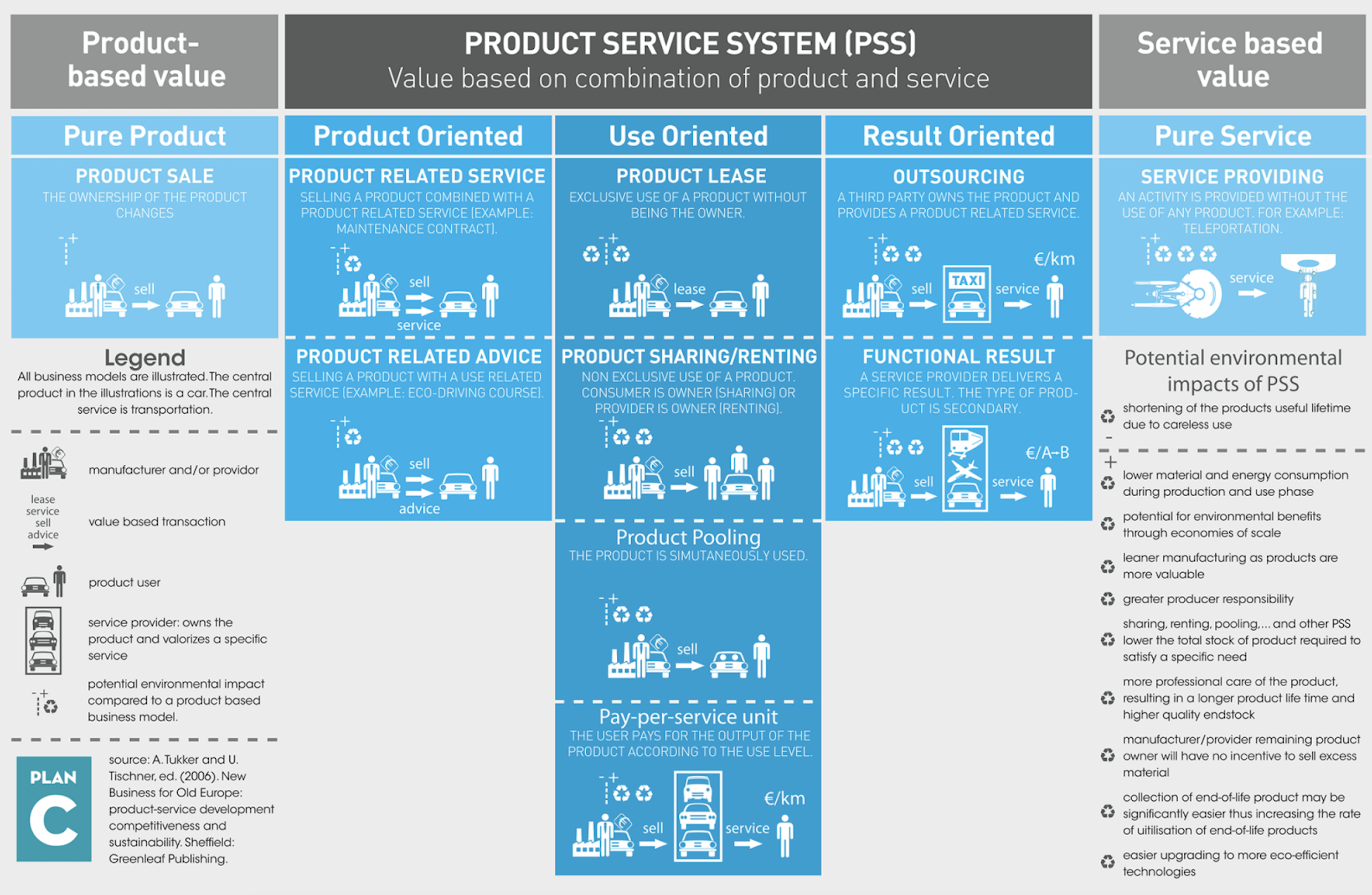

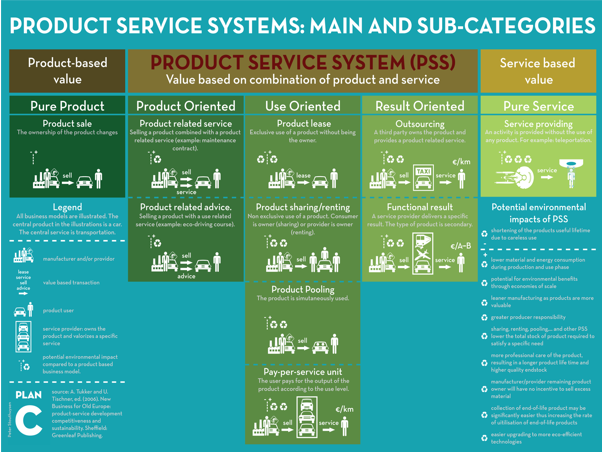

Intentional product-service systems design is the way towards sustainable, circular economy, solutions for a future society! Q & A with…

About the profile

This Knowledge Foundation (KKS) profile+ center is based on a clear vision and objective regarding model driven development and decision support for sustainable product-service system (PSS) innovation and is building on the further deepening of the ongoing profile work with perspectives of raising international recognition through further presence in top publications, partnering with academics internationally, and also affecting educational programmes at BTH.

The ongoing digitalisation is an already integrated part of the work, while the profile+ is extending the Data Driven Design approach based on Internet of Things (IoT) progress and access to live data from solutions in the field and the usage of machine learning/AI in development and industry 4.0 approaches in production .

The research focus is model-driven sustainable product-service system innovation. The concept of model-driven means that throughout the development process using models (virtual representation of reality) as communication media in order to shorten development cycles and improve multidisciplinary understanding. By also adding capability to collect live data from machines via connected sensors (Internet of Things – IOT) and finding patterns and solutions using big data analytics (including AI and Machine Learning) creating the potential for digital twin approach, the aim is to increase the profiling in this research even further.

Vision

An internationally leading research environment and the first-hand choice of partners who want to lead the way to a sustainable society through competitive product-service systems supporting a circular economy.

Objective

In co-production mode develop, disseminate, and integrate relevant, user-friendly and efficient computer aided support methods and tools for sustainable product-service system innovation into business leaders’, business developers’ and product developers’ working environments that enable industry to thrive in the changing global context, supported by both simulated and real data using internet of things and AI/machine learning.

Driving research question

How can we design a simulation, and data, driven PSS process where societal challenges are used as a driver for innovation, and methods and tools from diverse disciplines (engineering, sustainability, economics etc.) are linked in a decision environment, enabling value creating life-cycle solutions?

Project information

Project leader & Centre Director: Prof Tobias Larsson

Time span: 2013-2019 Profile, 2019-2022 Profile+

Funding: 163 MSEK (110 budget and 36 MSEK KK Foundation profile funds, 53 budget and 18 MSEK KK Foundation profile+ funds)

Partners:

- Aura Light International (2013-2019)

- Avalon Innovation (2013-2019)

- Dynapac Compaction Equipment

- GKN Aerospace Engine Systems

- Holje International Group

- Roxtec International (2019-)

- Tetra Pak Packaging Solutions AB

- Volvo Car Corporation (2019-)

- Volvo Construction Equipment

- Industrigruppen Karlskrona (affiliated network partner)

- Techtank (affiliated network partner)

- Blekinge Institute of Technology

- The Knowledge Foundation

Centre Director

Research areas

The industrial relevance is threefold:

- increased capabilities to mitigate risks, explore opportunities, and take informed decisions early on,

- increased opportunities to bring new sustainability-driven innovations to the market and

- research findings, methods and tools that help industry undertake the changes on several levels that are necessary to stay competitive.

The driving research question is broken down into several sub-questions that are being dealt with in the research tracks of MD3S+ as presented below.

RT1 – Value Driven Design

(mechanical engineering, innovation engineering)

- How can value models iteratively translate customers' desires into terms that are meaningful for PSS design decision-making?

- How can a PSS process look like that supports a system of systems perspective and different component life-cycles over the course of PSS deployment?

- How to drive innovation in multi-stakeholder environments (both internal/external stakeholders)?

RT2 – Sustainable Product Development

(sustainable development, mechanical engineering)

- How can sustainability criteria and indicators guide the finding of generic LCA data to be used in a model-based decision support for value and sustainability assessment?

- How can a risk perspective be applied to identify, assess, and manage potential consequences of sustainability-related decisions?

- How to define a methodology to identify and assess how strategic sustainability criteria can be integrated in requirements and model how they affect value criteria?

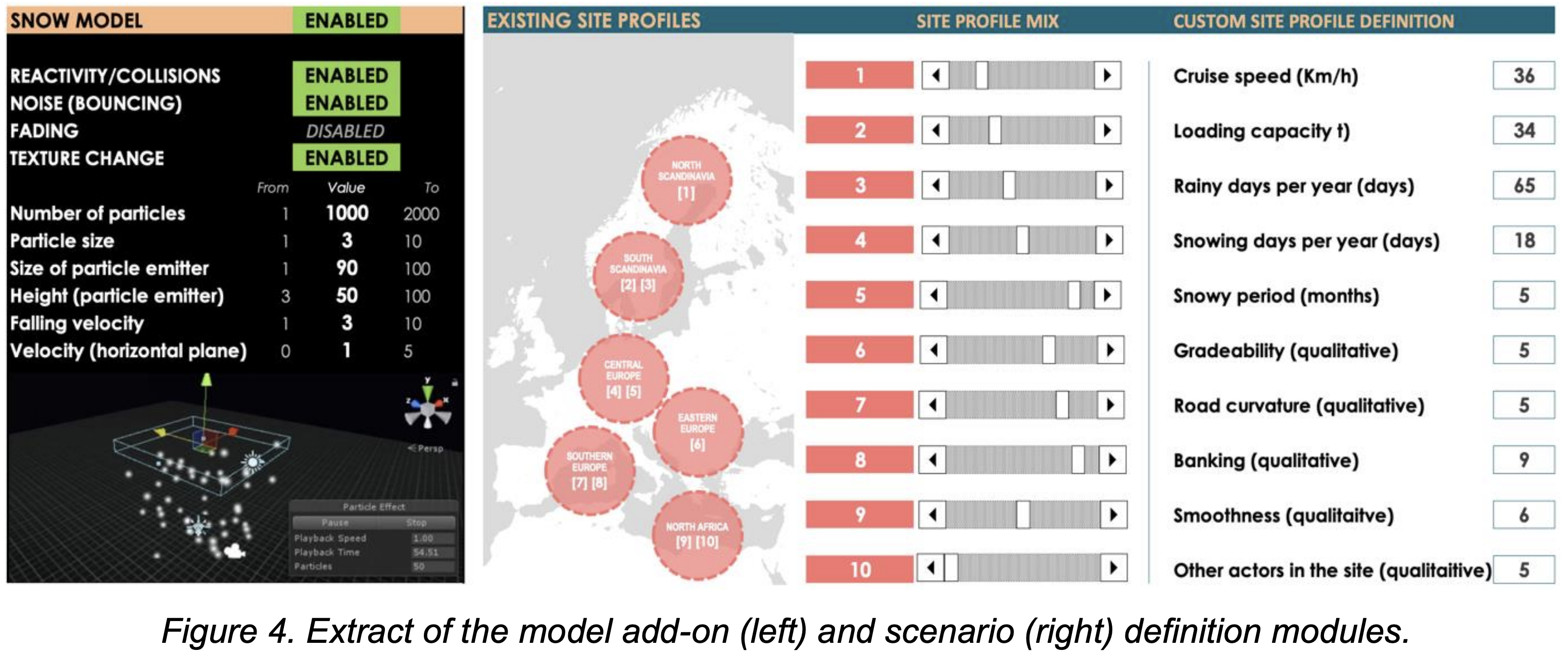

RT3 – Simulation Driven Design

(mechanical engineering, data science, electrical engineering)

- How to assess model maturity levels: confidence in models and model generated results as a basis for decision making?

- How to use/asses IoT data-driven design and machine learning configurators for conceptual design?

- How to perform design automation tasks in a multi-discipline environment for decision making?

Research publications

AI-Driven Comprehension of Autonomous Construction Equipment Behavior for Improved PSS Development

Abstract This paper presents an approach that utilizes artificial intelligence techniques to identify autonomous machine behavior patterns. The context for…

A Value-Driven Design approach for the virtual verification and validation of autonomous vehicle solutions

Abstract Autonomous vehicle solutions (AVS) are regarded as a major enabling technology to support the realization of 'total site solutions'…

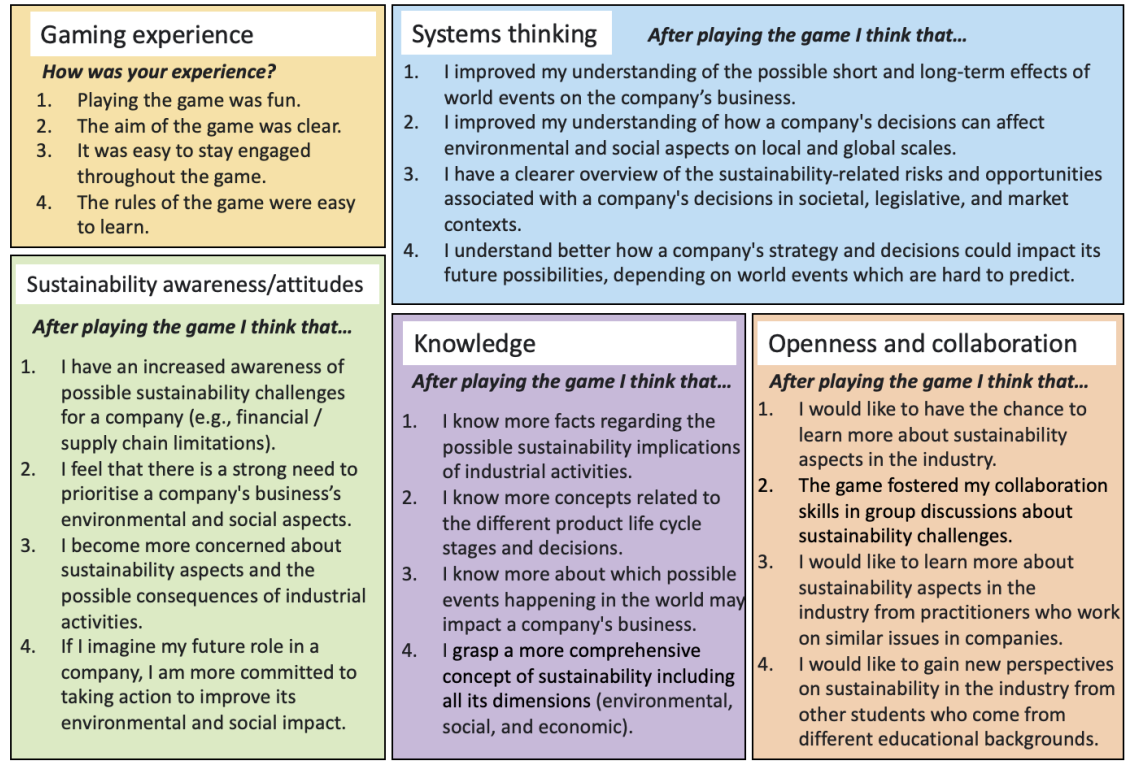

A STUDY ON THE POTENTIAL OF GAME BASED LEARNING FOR SUSTAINABILITY EDUCATION

Abstract Academic institutions are increasingly required to prepare future practitioners to face complex sustainability challenges. The need to foster the…

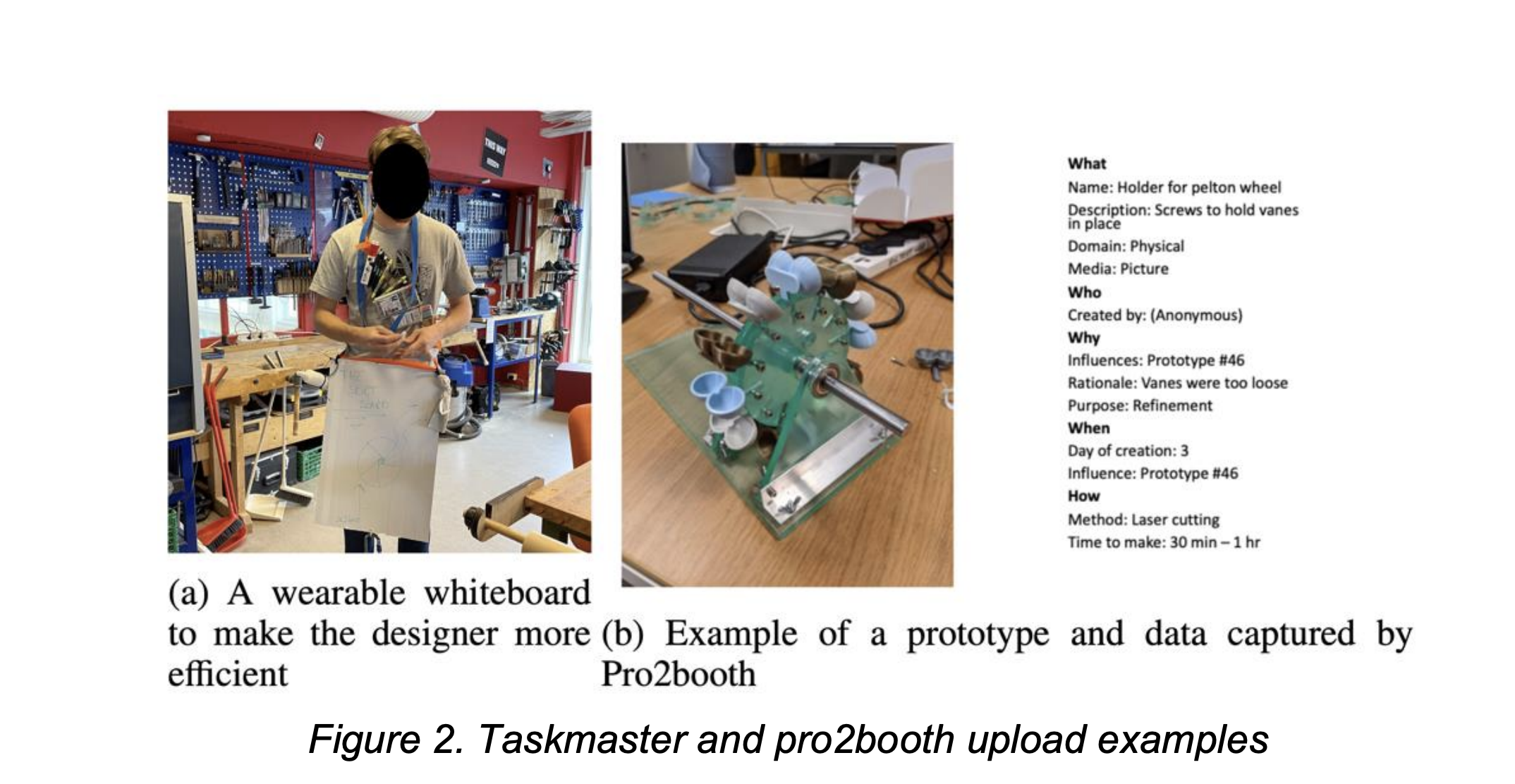

VIRTUALLY HOSTED HACKATHONS FOR DESIGN RESEARCH: LESSONS LEARNED FROM THE INTERNATIONAL DESIGN ENGINEERING ANNUAL (IDEA) CHALLENGE 2022

Abstract The International Design Engineering Annual (IDEA) Challenge is a virtually hosted hackathon for Engineering Design researchers with aims of:…

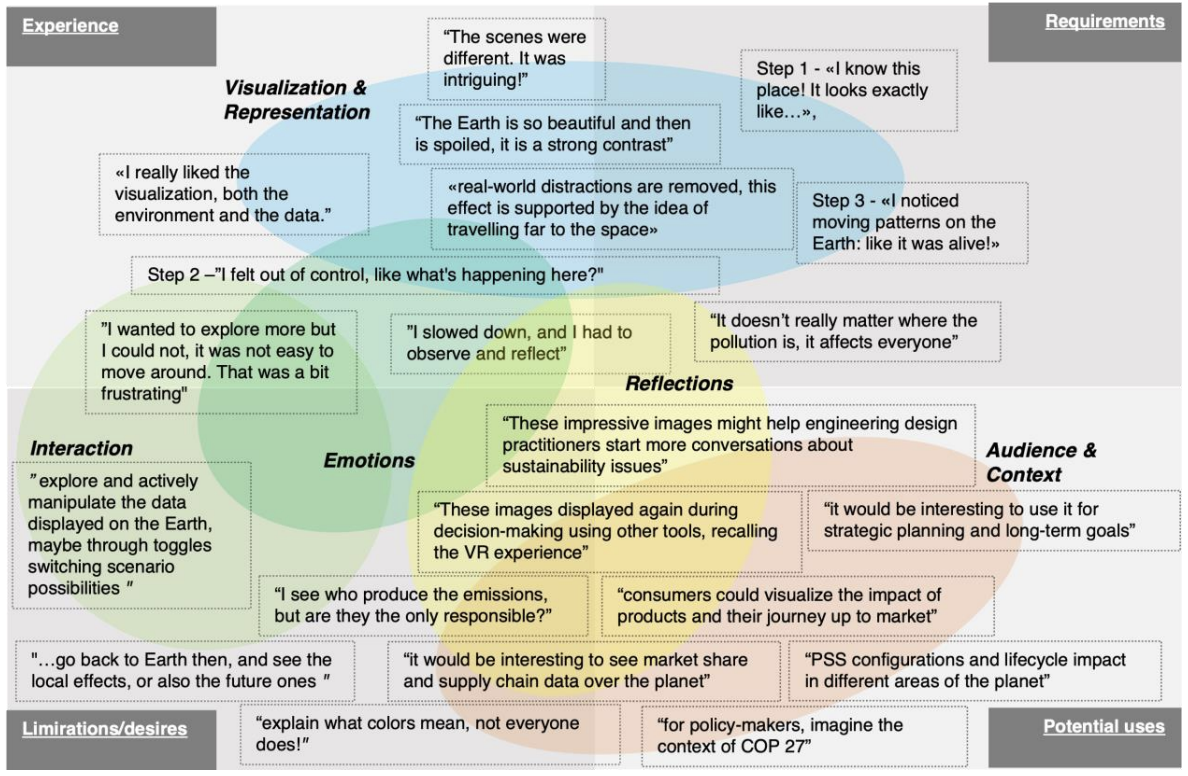

BEYOND THE OVERVIEW EFFECT: A VIRTUAL REALITY EXPERIENCE FOR SUSTAINABILITY AWARENESS IN DECISION-MAKING

Abstract The challenges of sustainable development require a consistent transformation of decision-making practices in society and in the industry. In…

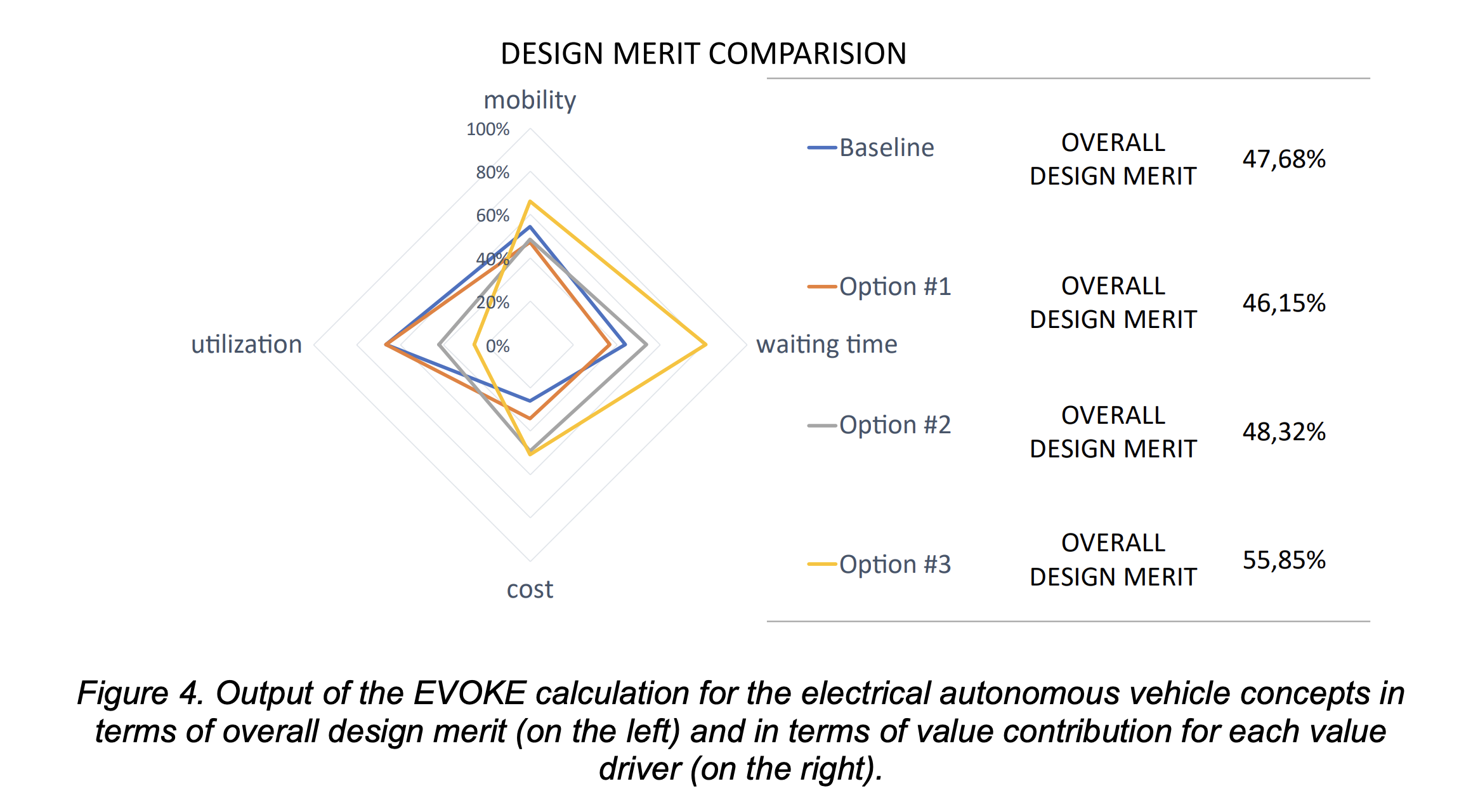

MITIGATING UNCERTAINTY IN CONCEPTUAL DESIGN USING OPERATIONAL SCENARIO SIMULATIONS: A DATA-DRIVEN EXTENSION OF THE EVOKE APPROACH

Abstract The paper presents an approach where the iterative replication of Discrete Event Simulations on future operational scenarios is used…

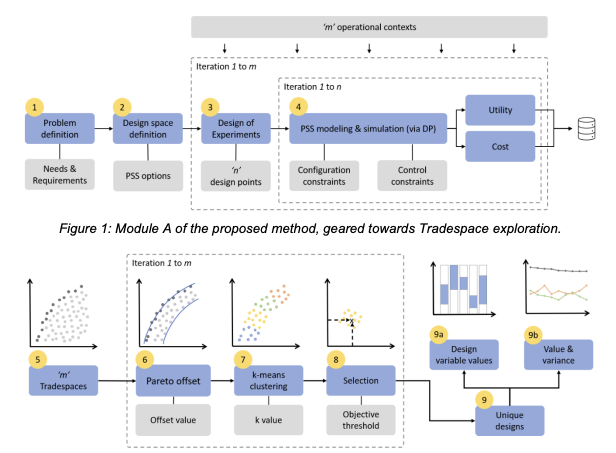

SUPPORTING CHANGEABILITY QUANTIFICATION IN PRODUCT-SERVICE SYSTEMS VIA CLUSTERING ALGORITHM

Abstract The design of Product-Service Systems (PSS) is challenging due to the inherent complexities and the associated uncertainties. This challenge…

Conceptual Design in Informal Metalworking Microenterprises of Tanzania

Abstract Product design is a key aspect of human intelligence and creativity, attracting not onlyexperts but also people without any…

A Study of the Boundary Conditions in the ISO-16630 Hole Expansion Test

Abstract As new and more advanced sheet metal materials are introduced to the market, more accurate techniques for determination of…

73 Comments on “Model Driven Development and Decision Support | 2013-2022”

Comments are closed.