eTWIN – Digital-Twin enabled Transition into Electromobility and Autonomy in Construction Equipment | 2021

- Post by: Tobias Larsson

- 29th March 2021

- 4 Comments

Concluding remarks

Wrapping up the eTWIN project, with Alessandro Bertoni

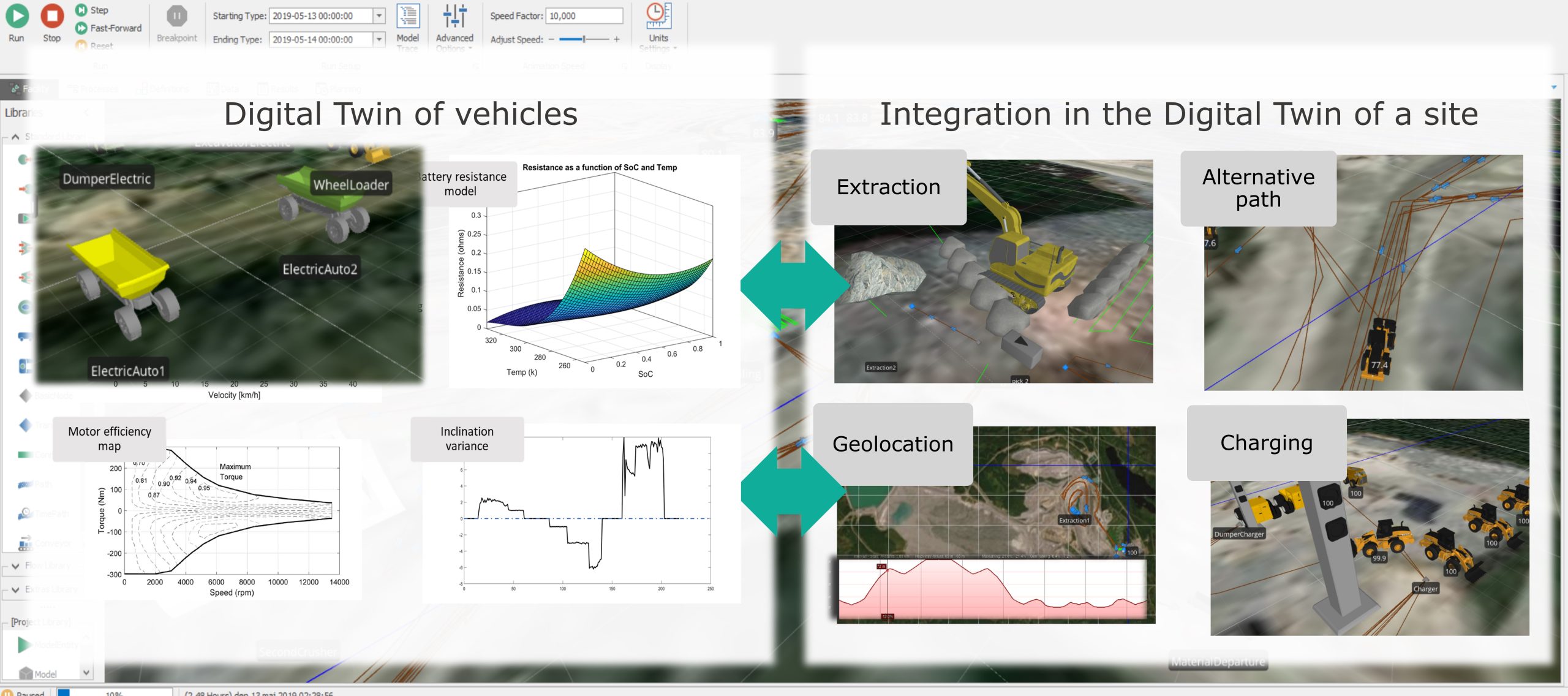

This project has demonstrated the capabilities of creating a digital twin of typical mining operations by combining the simulation of the energy consumption and performances of single electrical vehicles with specific productivity requirements and topographic configuration of the overall mining site. This allows the evaluation of the economic and environmental impact of the transition toward electromobility in mining, as well as supports the requirements definition for electrical vehicles.

The project encompassed the simulations of electrical haulers based both on real data provided by the partner company and on a fictitious scenario (to avoid IPR during dissemination). Such simulations were coupled with discrete event simulations of an overall mining site (importing topographical information form public online databases). The integration allowed the simulation of the impact of different design modifications on the global site productivity, cost, energy consumption and emissions.

Results

The result of the project allows engineers designing fully electrical machines to quickly forecast the economic and environmental impacts of the new machines in a reference mining site. This is expected to consistently reduce the development time and the time to market electrical and autonomous vehicles in the construction equipment, while at the same time lowering the environmental impact and delivering a safer workspace by moving away workers from risky environment.

Original project description

Construction equipment manufacturers have developed and introduced their first fully autonomous and fully electrical machines, promoting the vision of running fully autonomous and potentially CO2 neutral as the natural long-term objective of such an innovation process. The new scenario will drastically reduce air pollutants, increase workers’ safety, and create value for customers by reducing the cost of operations. However, while the possibility to drive fully electrically and autonomously on a single machine is nowadays a reality, there is still a low understanding of the implications of scaling this innovation up to a network of machines and a large collaborating system, especially regarding the surrounding infrastructure.

This project consists of a pre-study that will be run at the department of Mechanical Engineering at the Blekinge Insitute of Technology (BTH) and will be sponsored by Volvo Construction Equipment (VCE). The project will enable the creation of a digital twin of the typical operations of a mining and quarry site, including time, fuel consumption, emissions, and productivity, that, applied to a network of quarry and mining sites, will allow forecasting the systems level impact of the transition to electric and autonomous sites, in terms of economical and environmental effects. In this respect, the project aims to support the electromobility and autonomy transition by the quantification of direct and indirect economical and environmental strengths, weaknesses, threats, and opportunities, for value creation and environmental performance improvement.

PROJECT INFORMATION

BTH project leader: Associate Professor Alessandro Bertoni

Time span: 20210501-20211001

Budget: 685 000 SEK (VINNOVA)

Partners:

- Blekinge Institute of Technology

- Volvo Construction Equipment

- VINNOVA

Related Links

Presentation at Mining Innovation Program day 2021

https://www.youtube.com/watch?v=mV26np5a0ck&t=15s

- 24 miljoner till att stärka miljö- och klimatutmaningar inom gruvindustrin

- Model Driven Decision Arena

- Press: Nya arbetssätt för emissionsfri vägbyggnation

- Model Driven Development and Decision Support

- VINNOVA: Digital-Twin enabled Transition into Electromobility and Autonomy in Construction Equipment (eTWIN)

4 Comments on “eTWIN – Digital-Twin enabled Transition into Electromobility and Autonomy in Construction Equipment | 2021”

Comments are closed.