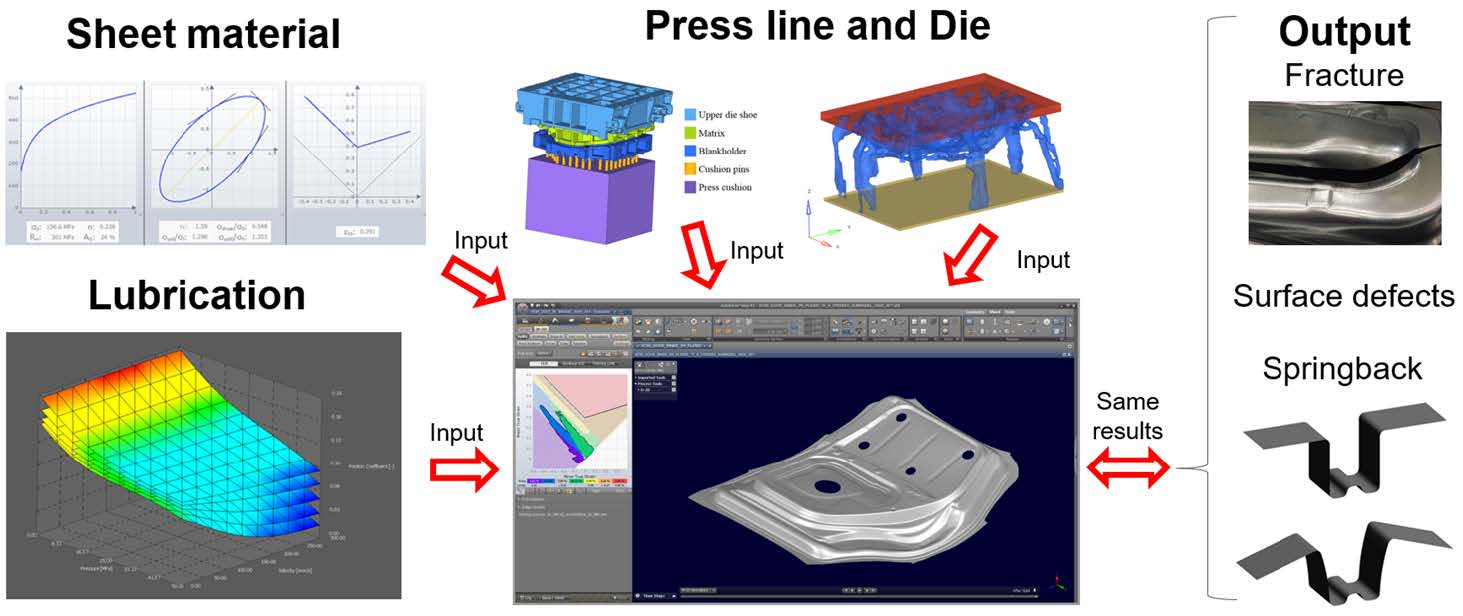

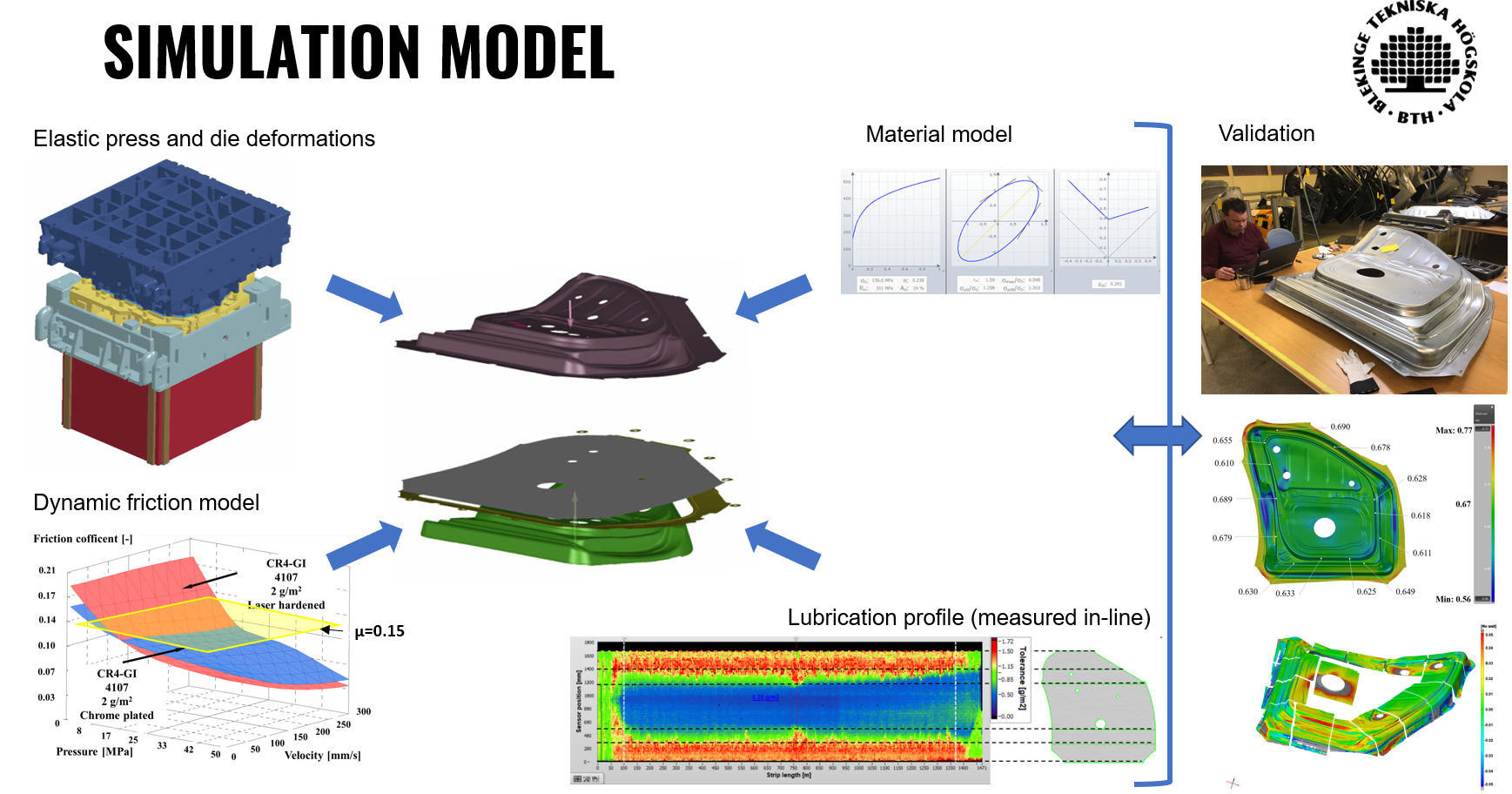

ABSTRACT Sheet metal forming (SMF) simulations are traditionally carried out with rigid active forming surfaces. This means that the elasticity and dynamics of presses and die structures are ignored. The only geometries of the tools included in the simulations are the active forming surfaces. One reason for this simplification is the large amount of computational […]

Read More