Industry 4.0 Cyber Physical Factory!

- Post by: Tobias Larsson

- 2nd March 2020

- 5 Comments

With the ongoing transformation of industrial product development and production, and especially how Internet of Things (IoT), smart factories, cyber-physical systems and big data are driving technology capability – solutions must be ever faster, more diverse, more flexible and more intelligent, as well as sustainable, feasible, viable and desired.

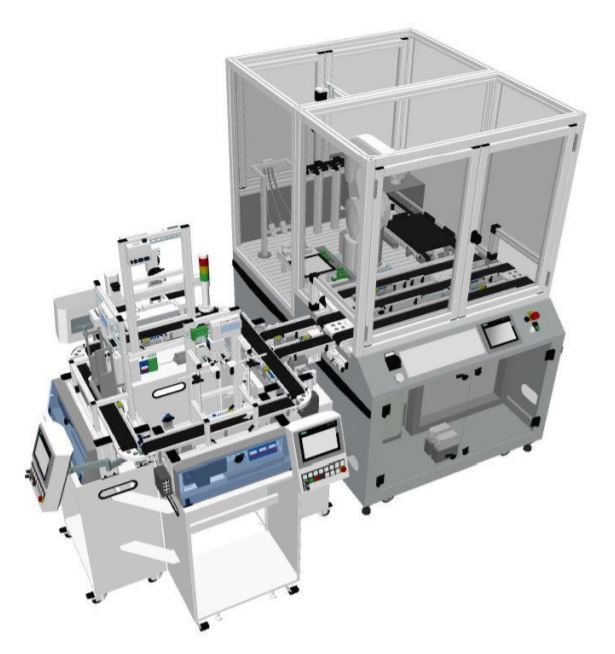

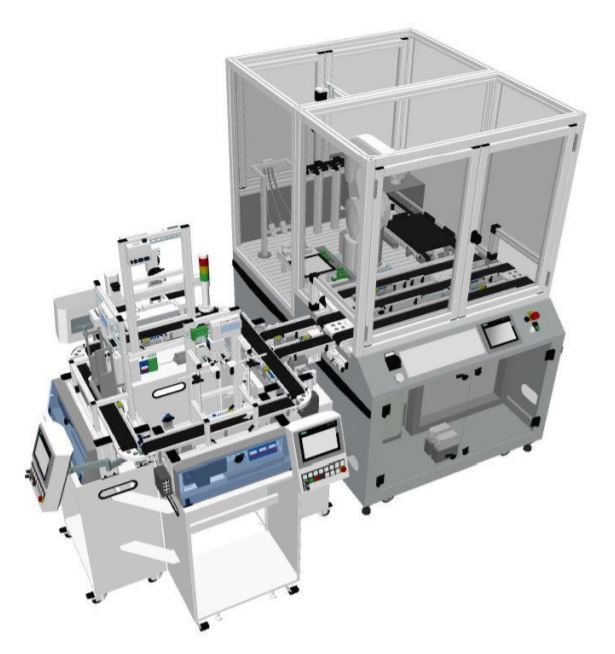

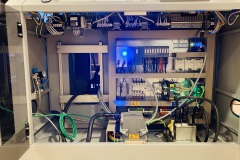

Together with Festo we have now installed an industry 4.0 facility to support our educational and research environments at PDRL and BTH.

The Cyber Physical Factory will be used as a platform both in research and training. The new smart production system will be placed in or Innovation Labs, where students and companies can work and learn together in the field of Industry 4.0. The CP Lab will be operational from September 2020.

A list of the main areas / equipment (contact Tobias for full specification):

- Robot stations

- An Autonomous Mobile Robot (AMR), Robotino (option)

- RFID, NFC and other I4 technologies

- Augumented Reality app with tablets

- MES system and cloud solutions

- Ciros for Digital Twin applications

- A mix of Festo and Siemens PLC

- Smart Maintenance (option)

- Cyber Security (option)

Areas of Research with the CP Lab:

- Robotics, Digital Twin, Production System, Artificial Intelligence, Big data analyses

Areas of Training with the CP Lab:

- New Industry 4.0 MSc program (AVANS programme development)

- New training program for professionals

The CP Lab is part of the research projects “Model Driven Development and Decision Support” and “Testarena Blekinge“.

For more information

- Professor Tobias Larsson, research director

- Peter Blaschke, BTH Innovation Labs

- Testarena Blekinge @ Blue Science Park

5 Comments on “Industry 4.0 Cyber Physical Factory!”

Comments are closed.