With a research platform in Mechanical Engineering and focusing Digital Product Development, we research methods, tools and rationale to support companies capability to innovative sustainable solutions with higher value to the customers.

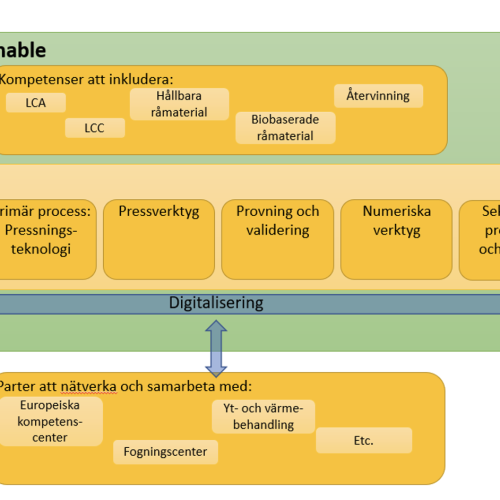

Product Development Research Areas within the field of mechanical engineering

The PDRL unit is highly specialized on in-depth knowledge on digital product development.

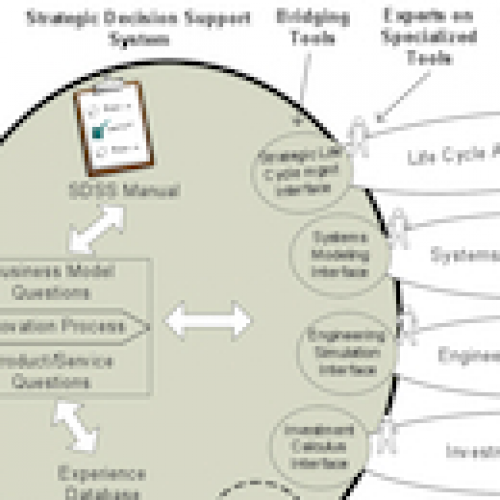

Our work is focused on developing the “engineers desktop" with digital methods and tools to support companies to deliver innovative product-service system concepts that support the transition to a future sustainability society.

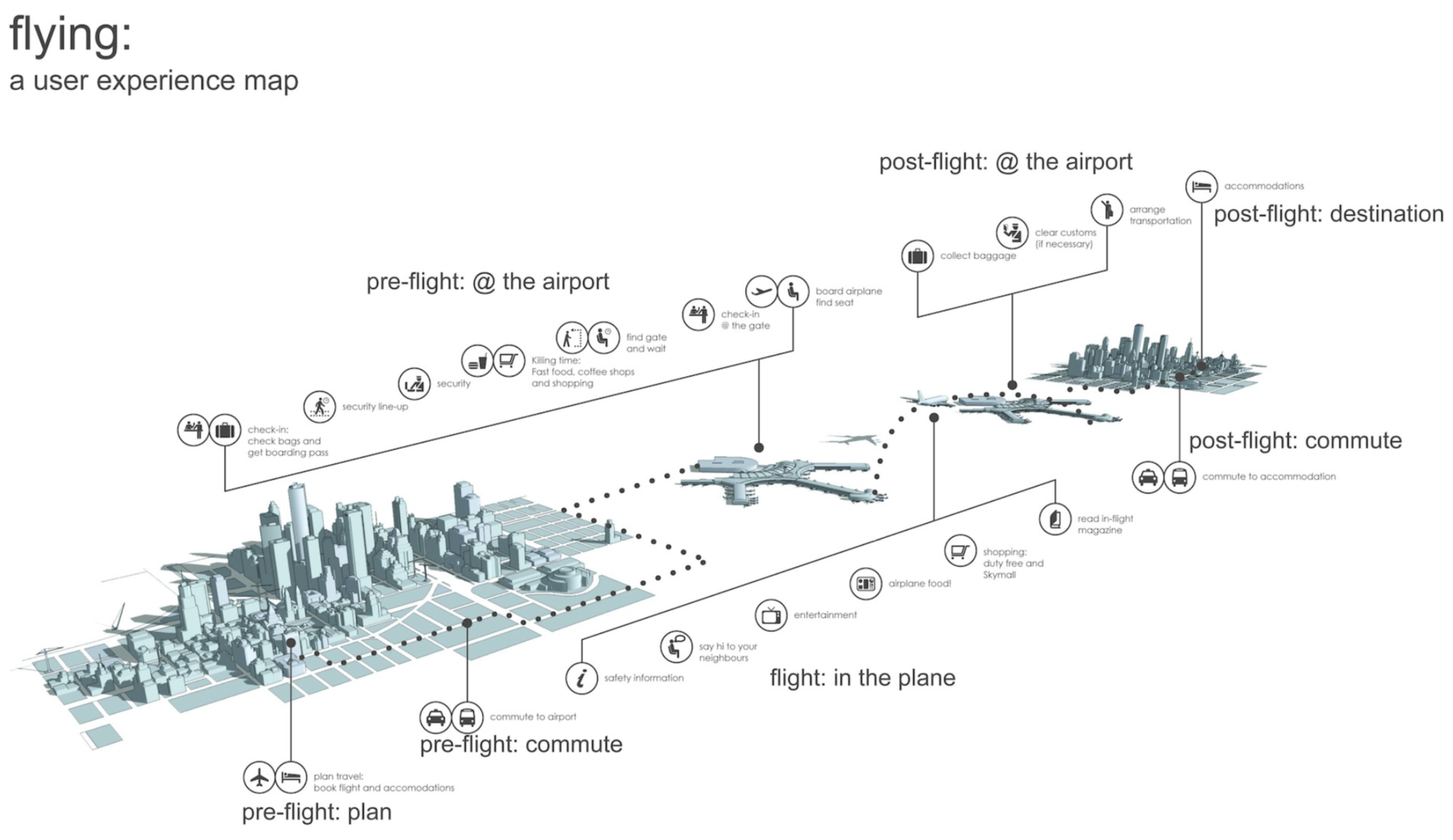

Design Thinking: The ability to in a user-centric way identify and work with needs and transform these into solutions (inspiration, ideation, implementation).

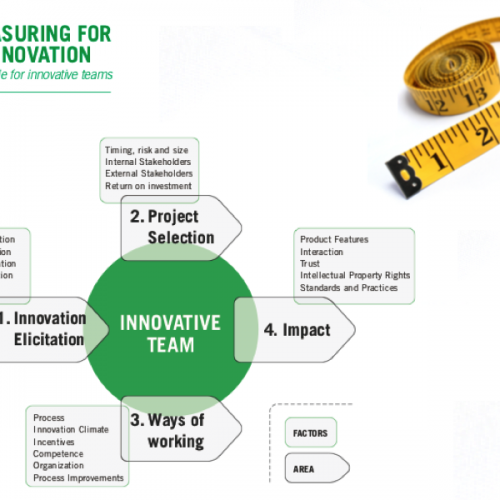

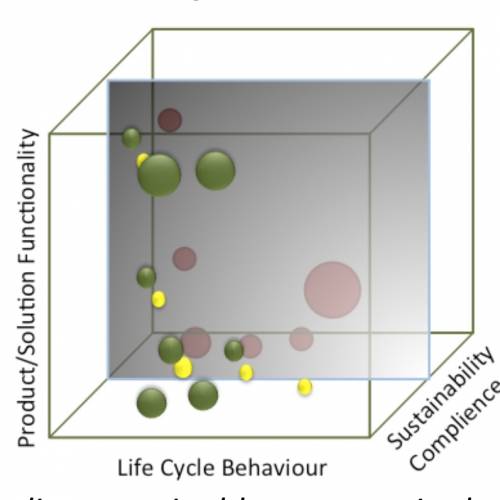

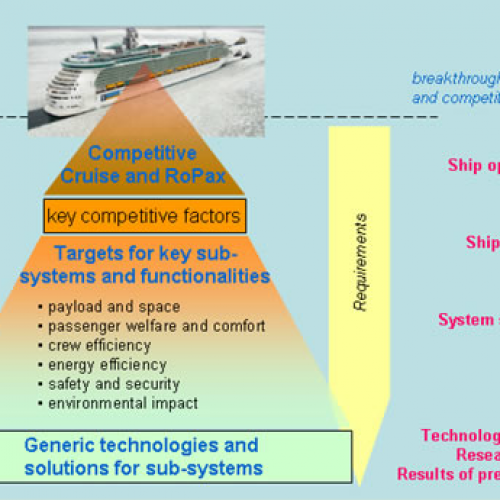

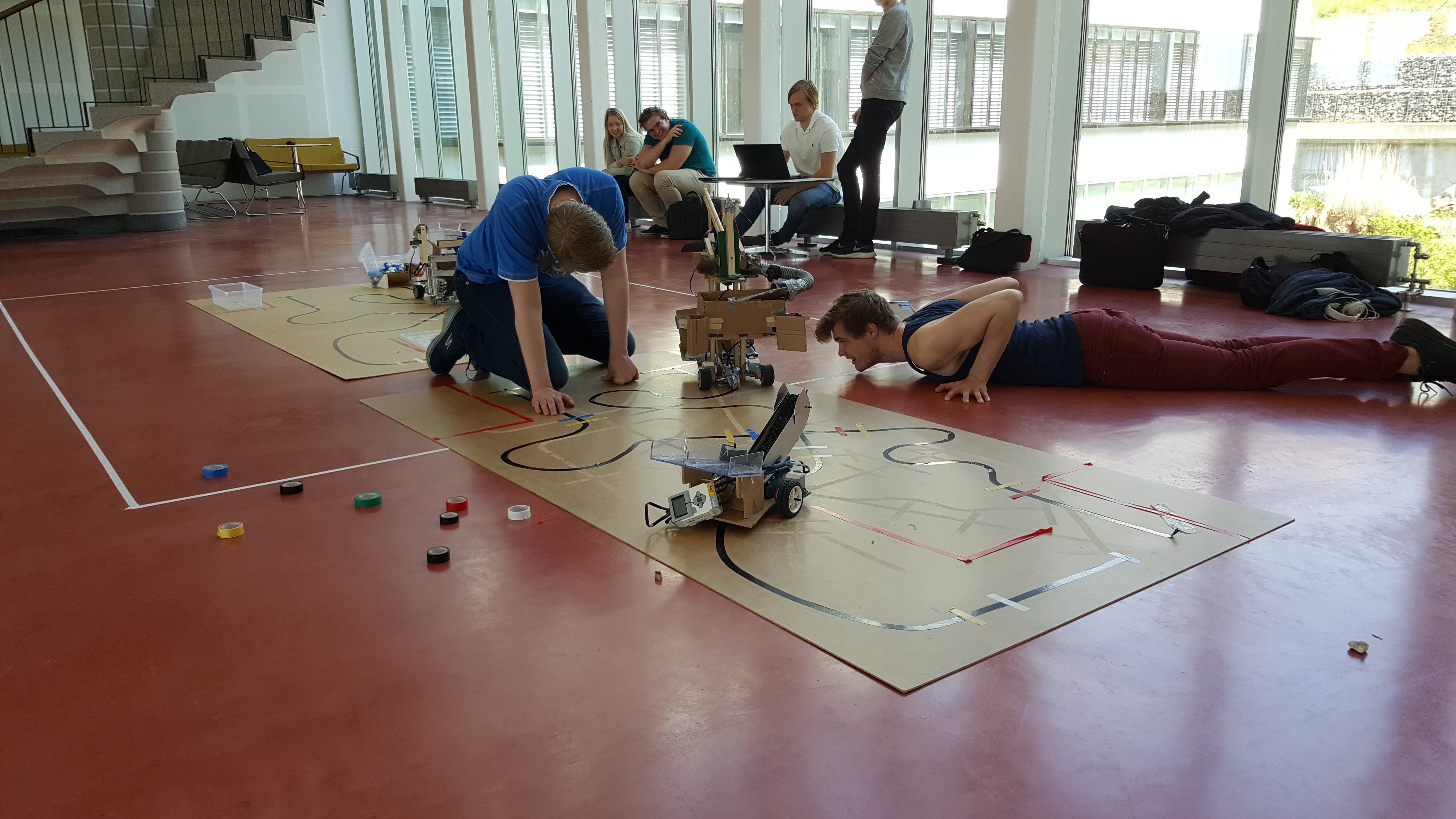

Innovative product development: Exploration. The ability to develop new products and offerings (engineering design, innovation methods, key performance indicators, creative methods for concept ideation and generation).

Disruptive methods and technologies: The ability to explore technologies that will change our society at the core (3D printing, Virtual Reality, Internet of Things) and the work processes to go with this (lean startup, agile innovation).

PSS Design Methodology: Development of function based solutions for a circular economy reasoning.

Value driven design: The ability to drive design and development of new solutions using perceived value as the driver. (Value driven design, Value Innovation, circular solutions).

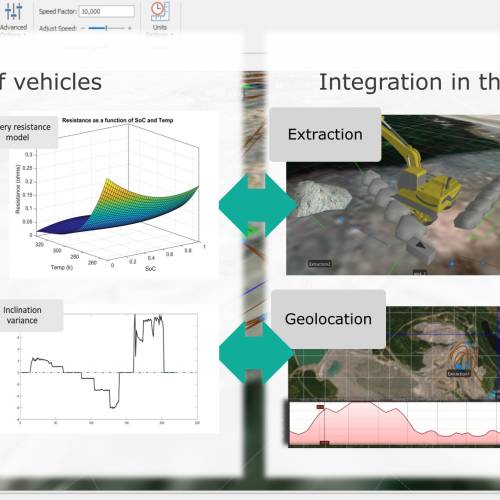

Design Automation: The ability to re-use and apply knowledge/information/data to speed up the development process. (Knowledge Based Engineering, Lightweight knowledge sharing, Case Based Reasoning, Design Rational Capture etc.)

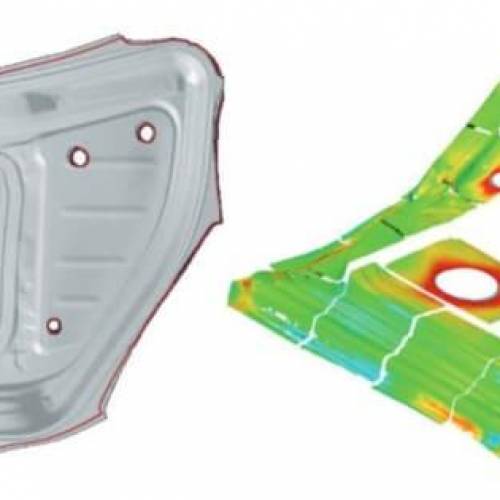

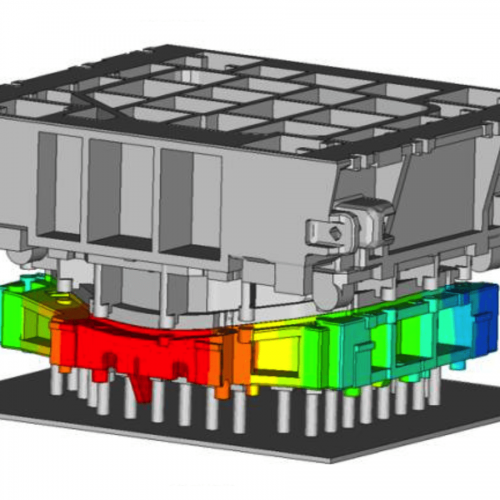

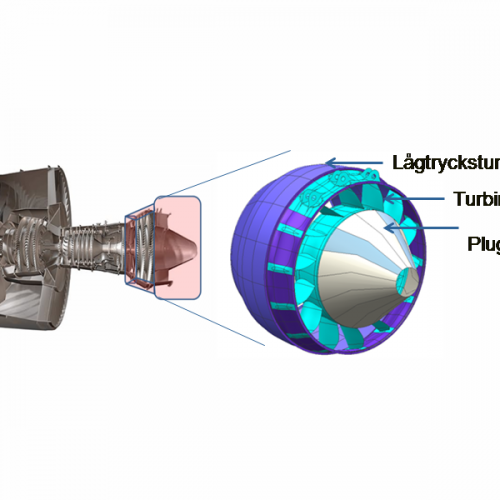

Simulation Driven Design: The ability to deploy simulation driven design and virtually build, test, and learn before entering the physical production space (Simulation-Driven Design, Discrete Event modelling, analytical models, process models, model-based systems engineering, data-driven design, data analytics).

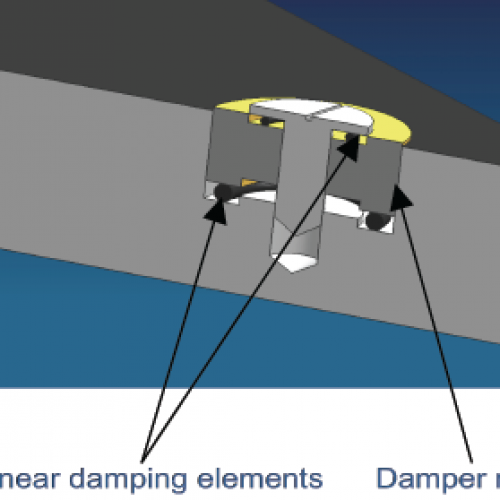

Structural Analysis: The ability to use engineering analysis methods to understand material behaviour and performance in engineering design. (fracture mechanics, non-destructive testing, acoustic methods, thermal loads etc.)

Application Areas

Applications

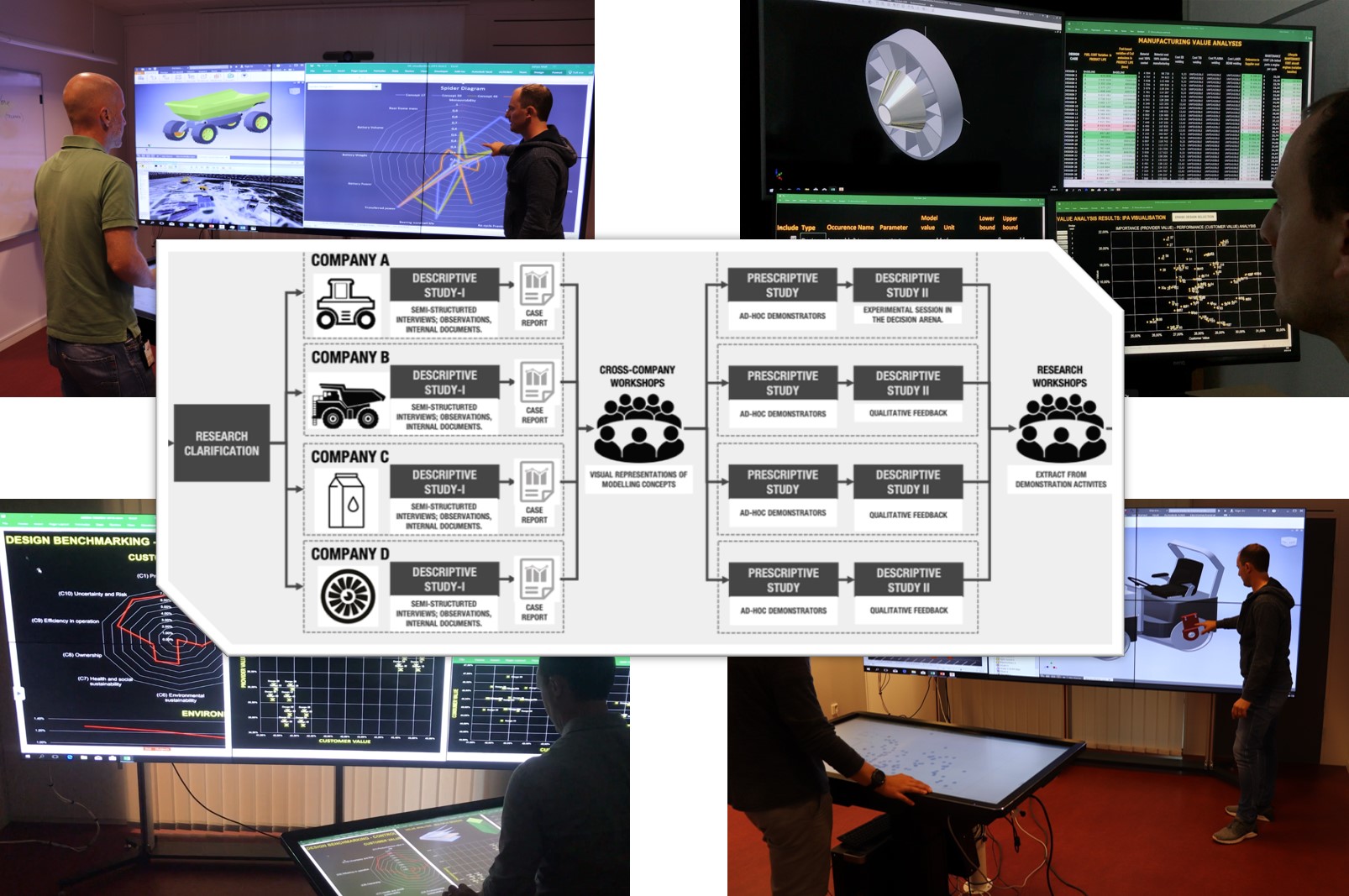

Applied approach

We work in close collaboration with our research and education partners.

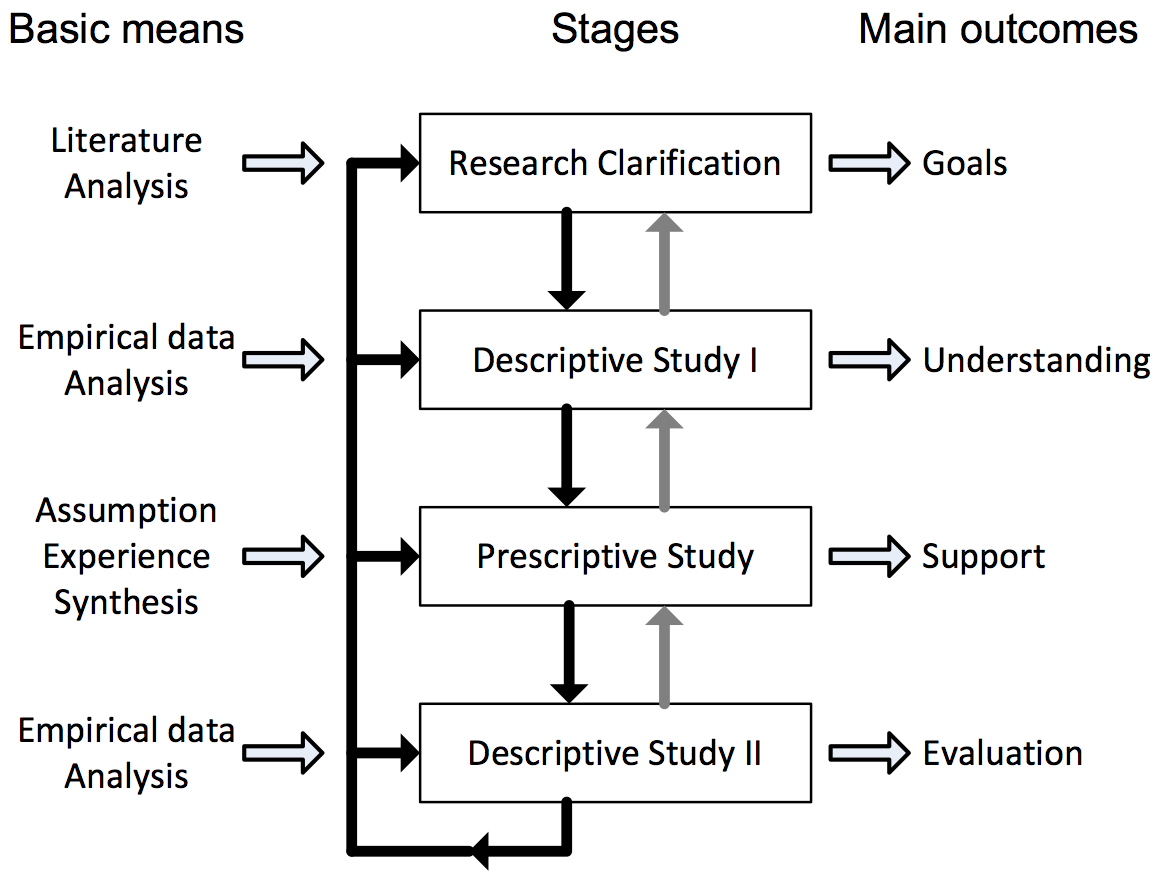

We aim to maintain an objective and unbiased view of the situations we study and research, while still deploying a methodological approach to the research studies.

We lean on Design Research Methodology as one of our fundamental planning tools for our research. This since we always se the situations as “broken and in need of fixing". For the engineering design researcher the glass is never half-full or half-empty; it is simply too big, too small, too heavy, too expensive etc. 😉

Testimonial