PREDICT | 2020-2024

- Post by: Tobias Larsson

- 28th October 2020

- 15 Comments

Concluding remarks and results

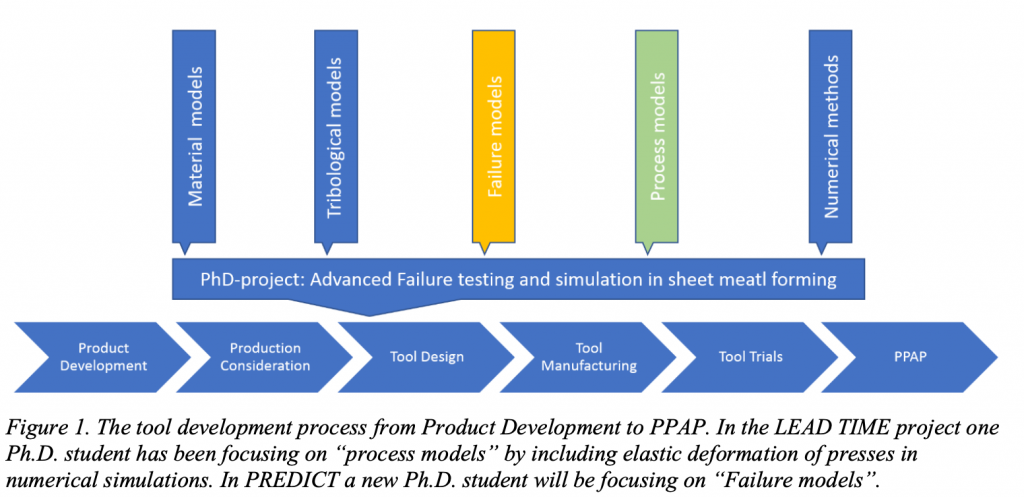

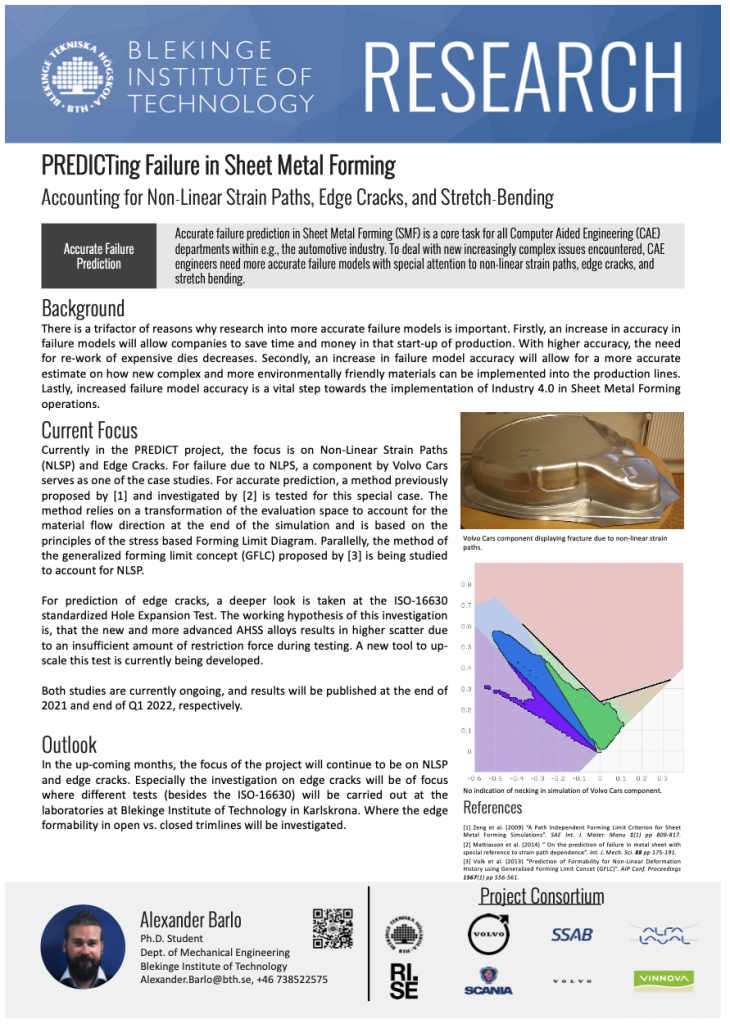

PREDICT has generated results and tools that are used to increase reliability of failure prediction of sheet metal forming simulation in finite element models (FE-model). The work in this project was focused to accurately model the effect of complex load cases like non-linear strain path (NLSP), stretch-bending and presence of edge crack in the formability of sheet metals like steel and aluminum alloys.

The effect of bi-linear strain path was experimentally performed on mild steel formability and findings were used to verify forming simulation of a critical automotive part. To bypass the NLSP effect on formability evaluation of sheet metal in FE-models, a strain path independent forming limit criterion was utilized. Outcome of NLSP study is published in two conference papers.

The strain localization during forming in shell element subjected to combined stretch-bend loads was successfully implemented in AutoForm FE-solver to evaluate risk on failure in automotive sheet metal stamping simulations. Studied results on a dual-phase steel and aluminum alloy showed that the forming limit is a function of the “stretching-to-bending ratio” and are published in a Journal.

Edge formability is often studied by sheet metal suppliers and automotive users through the hole expansion test (HET) in terms of hole expansion ratio (HER). The HER for a selected sheet metal usually varies in a wide range challenging its reliability. In PREDICT, HET was studied in a dual phase steel with modified boundary condition and full field strain measurement of the test samples and was concluded that restraining force of the sample during the test is not the primary cause of HER scatter. Similar scatter or uncertainty was numerically found in HET edge fracture strain. A systematic uncertainty quantification of HER in FE-model was studied and key factors effecting the scatter of HER and failure were identified, and the results are submitted for a journal publication.

During the project investigation, it was found that the failure/ necking in the sheet metal under forming has ambiguous definition among practitioners. The neck detection methods can be different and can depend on evaluator’s bias. Several works in PREDICT investigated and proposed a new/ modified neck detection method for defining the forming limit of the sheet metals and results are published in one journal and two conference papers.

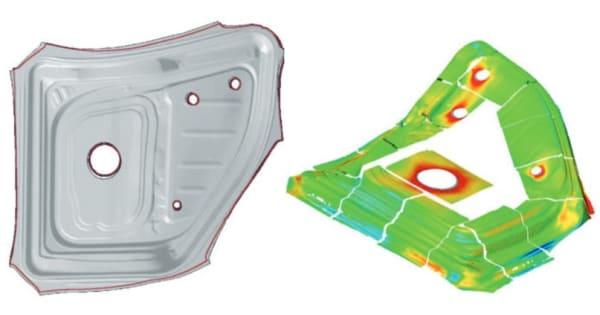

To demonstrate the maturity of forming simulation which was further improved through PREDICT and a use case of implementing machine learning to achieve forming process robustness, FE-simulation prediction and measurement data based meta-model was developed using Artificial Neural Networks for quality assurance in the sheet metal formingprocess. The forming operation of the front door (inner) of a Volvo XC60 vehicle was selected in the case study and the predictions from the developed meta-model agreed well with FE-model prediction of deformation and failure.

In total, the project has resulted in one Licentiate thesis, three Journal articles (2 accepted and 1 under review), 6 conference papers and 6 master’s theses. The project duration was extended by one month and 100% of the initial planned project budgets was utilized. In conclusion, PREDICT has increased accuracy in failure prediction by developing advanced formability evaluation methods, calibration techniques and effective FE-models for simulations.

- C1: Barlo, A., Sigvant, M., Pérez, L., Islam, M. S., & Pilthammar, J. (2022, May). A Study of the Boundary Conditions in the ISO-16630 Hole Expansion Test. In IOP Conference Series: Materials Science and Engineering (Vol. 1238, No. 1, p. 012031). IOP Publishing.

- C2: Barlo, A., Sigvant, M., Manopulo, N., Islam, M. S., & Pilthammar, J. (2022). Failure prediction of automotive components utilizing a path independent forming limit criterion. Key Engineering Materials, 926, 906-916.

- C3: Tuan Pham, Quoc, Md Shafiqul Islam, Mats Sigvant, and Perez Lluis Caro. “Prediction of forming limit diagram of automotive sheet metals using a new necking criterion.”In International ESAFORM Conference 2023, pp. 705-710. 2023.

- C4: Pham, Q. T., Islam, M. S., Barlo, A., & Sigvant, M. (2023, June). An evaluation method for experimental necking detection of automotive sheet metals. In IOP Conference Series: Materials Science and Engineering (Vol. 1284, No. 1, p. 012020). IOP Publishing.

- C5: Barlo, A., Sigvant, M., Kesti, V., Islam, M. S., Pham, Q. T., & Pilthammar, J. (2023, June). Determination of Edge Fracture Limit Strain for AHSS in the ISO-16630 Hole Expansion Test. In IOP Conference Series: Materials Science and Engineering (Vol. 1284, No. 1, p. 012027). IOP Publishing.

- C6: Barlo, A., Sigvant, M., Islam, M. S., Pérez, L., Olofsson, E., Al-Fadhli, M., … & Odenberger, E. L. (2023, June). Proposal of a New Tool for Pre-Straining Operations of Sheet Metals and an Initial Investigation of CR4 Mild Steel Formability. In IOP Conference Series: Materials Science and Engineering (Vol. 1284, No. 1, p. 012079). IOP Publishing.

- J1: Pham, Q. T., Islam, M. S., Sigvant, M., Caro, L. P., Lee, M. G., & Kim, Y. S. (2023). Improvement of modified maximum force criterion for forming limit diagram prediction of sheet metal. International Journal of Solids and Structures, 273, 112264.

- J2: Pham, Q. T., Islam, M. S., Barlo, A., Sigvant, M., Caro, L. P., & Trana, K. (2023). Modeling the strain localization of shell elements subjected to combined stretch–bend loads: Application on automotive sheet metal stamping simulations. Thin-walled structures, 188, 110804.

- J3: Uncertainty quantification for conical hole expansion test of DP800 sheet metal (Submitted for Journal publication)

- L1: Barlo, A. (2023). Failure Prediction of Complex Load Cases in Sheet Metal Forming: Emphasis on Non-Linear Strain Paths, Stretch-Bending and Edge Effects (Licenciate dissertation, Blekinge Tekniska Högskola).

- T1: Eriksson, A. (2021). Non-Linear strain paths in Sheet Metal Forming.

- T2: Aisvaran, C. (2021). Study of non-linear strain path in sheet metal forming.

- T3: Olofsson, E., & Al-Fadhli, M. (2022). Pre-Straining Operation: Prediction of Strain Paths Within a Forming Limit Diagram.

- T4: Bayat, H., & Abbasi, M. (2023). Investigation of the basic mechanics of edge cracking in sheet aluminum forming.

- T5: Palan, A. (2023). Analysis and Anomaly Detection in Sheet Metal Forming.

- T6: Abedisamarin, A., & Gholami, A. (2024). Effects of natural aging and low strain-rate on mechanical properties of aluminium alloy sheets used in automotive industry.

Original project description

The purpose of PREDICT is to achieve increased accuracy in failure predictions by developing advanced material models, calibration techniques and effective finite element simulations, which can enable unambiguous and reliable formability predictions. Specially, simulation failure predictions of phenomena such as non-linear strain paths, effect of strain rate, anisotropy and presence of edge cracks will be studied. Failure experiments will be performed, and characterization techniques will be developed to generate advanced FE-models that can easily be integrated to industry practice. Finally, FE- simulation driven metamodels based on AI will be developed to predict formability based on supplier data to make process adjustments for failure prevention. This will be an important step towards Industry 4.0 for the partners.

High prediction accuracy of FE-models will reduce rework loops on the forming surfaces of die and tools. This will prevent component failure, need for additional rework as well as fast-track the introduction of new lightweight materials to minimize environmental impact.

PREDICT gathers key competence from Swedish industry, research actors within manufacturing processes and FE-modelling, and leading experts in sheet metal forming.

BTH project leader: Md Shafiqul Islam

Time span: 20201101-20231231

Funding: 13 264 800 SEK (6 498 000 SEK VINNOVA, rest co-funding by partners)

Partners:

- BTH

- Alfa Laval

- RISE IVF

- Scania CV

- SSAB EMEA

- Volvo Cars

- Volvo Trucks

Dissemination material

Related Publications

- Modeling the strain localization of shell elements subjected to combined stretch–bend loads: Application on automotive sheet metal stamping simulations. 2023

- Improvement of modified maximum force criterion for forming limit diagram prediction of sheet metal. 2023

- Prediction of forming limit diagram of automotive sheet metals using a new necking criterion. 2023

- An evaluation method for experimental necking detection of automotive sheet metals. 2023

- Determination of Edge Fracture Limit Strain for AHSS in the ISO-16630 Hole Expansion Test. 2023

- Proposal of a New Tool for Pre-Straining Operations of Sheet Metals and an Initial Investigation of CR4 Mild Steel Formability 2023

- Failure Prediction of Complex Load Cases in Sheet Metal Forming: Emphasis on Non-Linear Strain Paths, Stretch-Bending and Edge Effects. 2023

- Failure Prediction of Automotive Components Utilizing a Path Independent Forming Limit Criterion. 2022

- A Study of the Boundary Conditions in the ISO-16630 Hole Expansion Test. 2022

Related Links

- Nya arbetssätt ska stärka svensk fordonsindustri: https://www.bth.se/om-bth/kontakt/press/#/pressreleases/nya-arbetssaett-ska-staerka-svensk-fordonsindustri-3046056

- Nytt forskningsprojekt vid BTH ska effektivisera fordonsindustrin: https://www.blt.se/olofstrom/nytt-forskningsprojekt-vid-bth-ska-effektivisera-fordonsindustrin-d43c7893

- Nytt projekt ska utveckla plåtformning: https://www.motormagasinet.se/article/view/747177/nytt_projekt_ska_utveckla_platformning

- BTH-forskning inom fordonsindustrin får VINNOVA-stöd: https://www.bth.se/nyheter/bth-forskning-inom-fordonsindustrin-far-vinnovastod/

- Nya arbetssätt ska stärka svensk fordonsindustri: https://www.verkstaderna.se/article/view/747019/nya_arbetssatt_ska_starka_svensk_fordonsindustri

- BTH projektsida: https://www.bth.se/forskning/forskningsomraden/produktutveckling/predict-prediktering-av-forstrackning-och-brott-for-komplexa-lastfall-inom-platformning/

15 Comments on “PREDICT | 2020-2024”

Comments are closed.