Applied simulation and internet of things for reduced waste during sheet metal forming

- Post by: Tobias Larsson

- 29th September 2020

- 1 Comment

Together with Volvo Cars (Olofström), Telenor Connexion and Blue Science Part as coordinator, a research and application project has been carried out within the “Test arena Blekinge” with the aim of transforming theory into practically applicable knowledge in Industry 4.0.

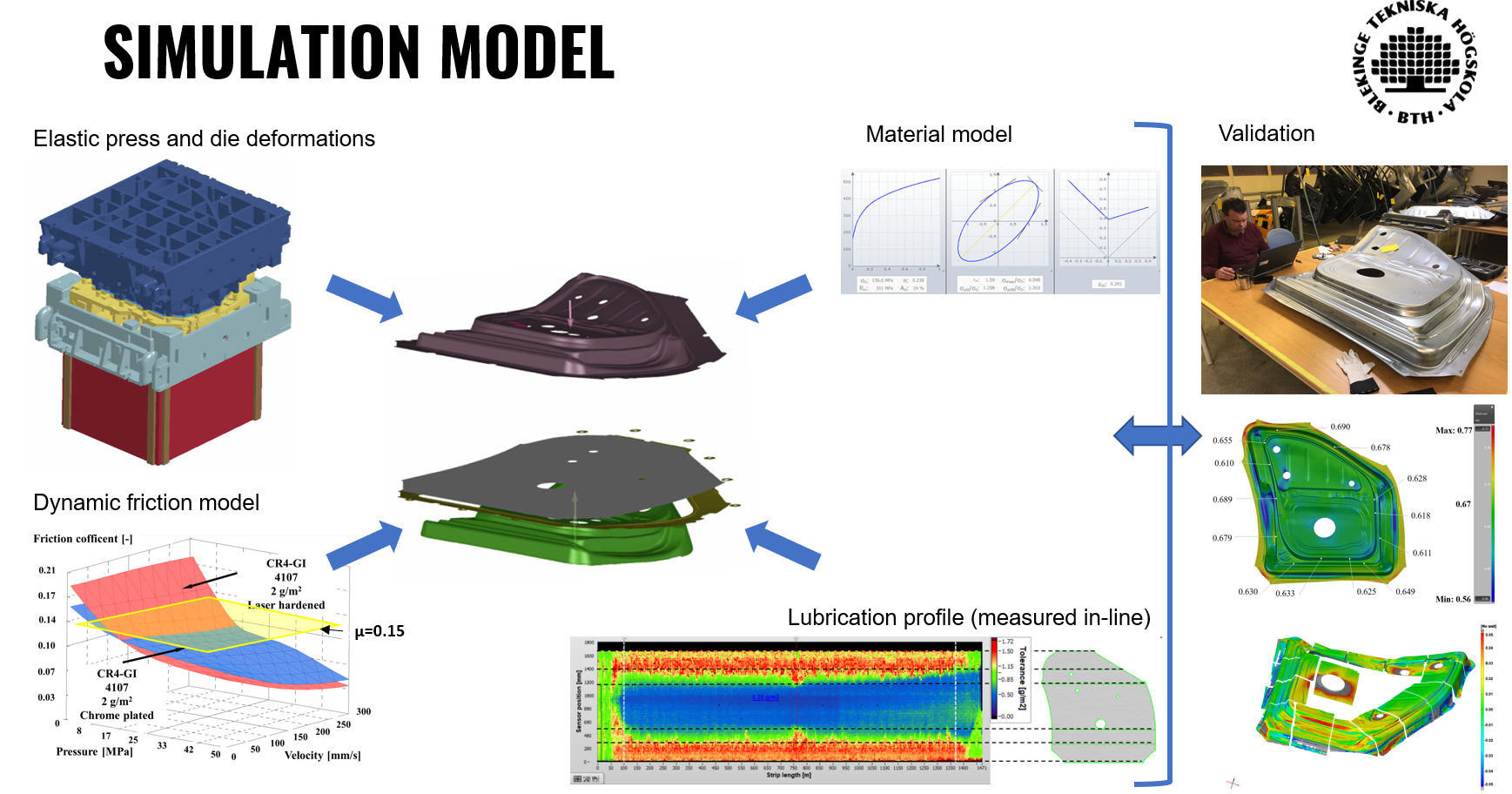

Industrial digitalisation has been going on since the 1990s, and with the development of the “Internet of Things” in the last decade, more opportunities are opening up for connecting physical production systems to virtual ditto. The research at PDRL is focused on a completely digital model-driven product development. In this project, doctoral student Sravan Tatipala and Professor Tobias Larsson have taken a closer look at how a connection between simulation models of a production process (sheet metal forming at Volvo Cars in Olofström) and the actual execution of this process (logged using connected sensors) can be used to faster convert input to the process based on production outcomes, thereby preventing the production of components that need to be corrected or discarded.

A first step towards a digital twin of the process has thus been taken in this project which has now been completed.

The work process can be used with advantage in the early phase of product development to predict and plan the production process, or for feedback of data from products in the field for updating product / production data.

The scientific results are to be found in Sravans’ Licentiate thesis (with appended papers) “Sheet metal forming in the era of industry 4.0: using data and simulations to improve understanding, predictability and performance” and a summary of the presenation is to be founde here.

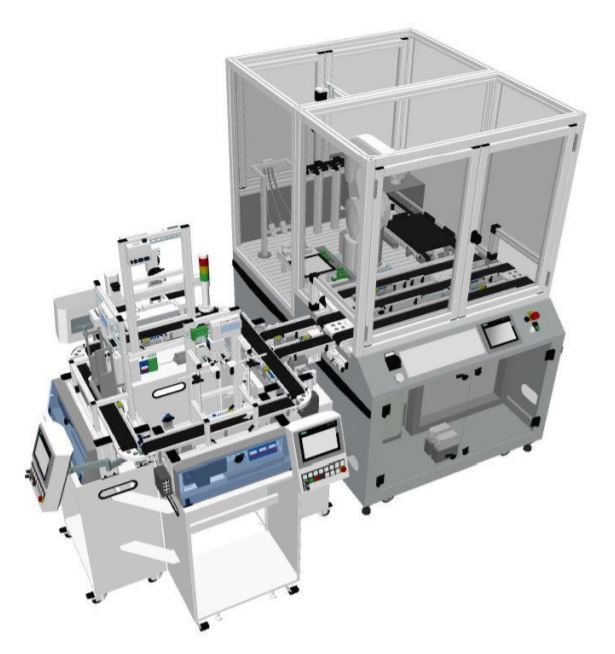

Since the project had as a goal to create a lab for companies to be siupported in the digital transformation a Cyber Physical Lab has been created at BTH where an industry 4.0 installation will be operational pending November 2020.

Hear the participating parties in the research project talk about Test-Arena Internet of Things in the video below.

More information

- Project pages at Blue Science Park

- Ny testmiljö inom framtidens industri

- Blue Digital Testbed

- Research areas involvded in the project.

- Professor Tobias Larsson, PhD candidate Sravan Tatipala, Adjunct PhD Mats Sigvant (Volvo Cars).

1 thought on “Applied simulation and internet of things for reduced waste during sheet metal forming”

Comments are closed.