Depeening the Virtual Production skills at BTH!

- Post by: Tobias Larsson

- 21st February 2024

- 1 Comment

Generative AI

Visiting and taking part at the Gothenburg Film Festival, BTH participated with an overview of application areas for generative video in movie production at Gothenburg Film Studio’s open film industry meeting, which this year focused on AI. Andrea Nordwall was the key person from BTH at the event.

At the same event, BTH’s Karlskrona-based partner in virtual production; iStudios Visuals was met with spontaneous applause when they were able to tell that the plans for a virtual production studio on campus Gräsvik at BTH will become a reality in 2024 (read about the Virtual Production Studio Lab project here: https://www.productdevelopment.se/virtual-production-studio-lab/ ).

Interest in generative AI in the film industry is great. During the autumn, BTH visited the film university Université Côte d’Azur in Cannes. During the spring, BTH held workshops at the University of Cannes to train filmmakers about application areas for generative AI for film production. The workshop was a collaboration with Blue Science Park and is part of the project T.A.B. – Innovation Hubs for Tech, Art and Business.

First university course in Virtual Production

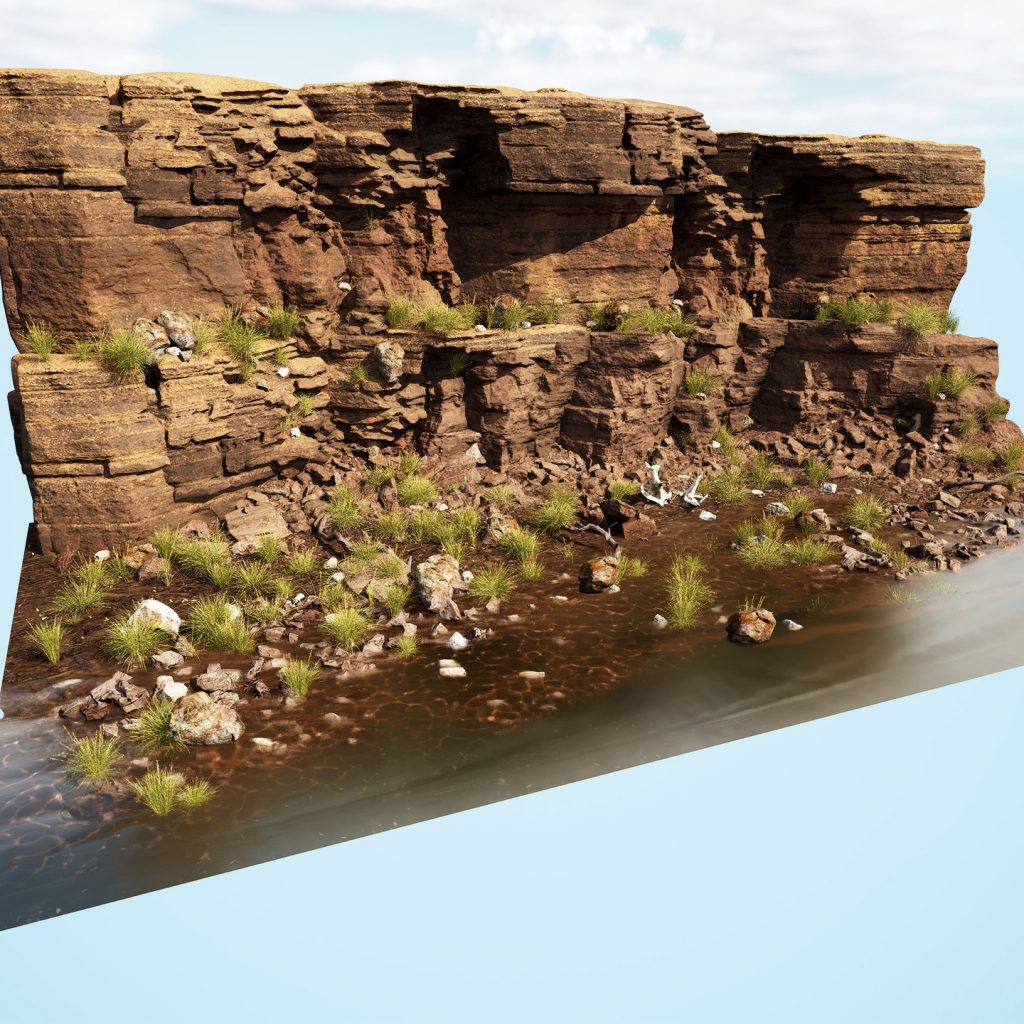

During the latter part of the autumn, BTH gave Sweden’s first university course in Virtual Production (ME1654 Virtual Production). The technology, which is based on replacing traditional physical film sets with digital environments, is used today in major productions such as The Mandalorian, Blade Runner 2049, House of Dragons and Barbie. Virtual Production place high demands on being able to build complex, photorealistic and dynamic 3D environments in a short time and with high quality, which are optimized to be rendered in real time by a rendering cluster and displayed on large screen walls and synchronized with a film camera.

During the autumn course, students have built a projector-based environment with a nine meter image area and tracked a physical camera with radio beacons, while awaiting the LED based VP studio of +15×4 meters coming in the VPSL. The students have built three-dimensional environments that have incorporated 3D-modeled objects with 3D-scanned objects and simulated digital humans.

The technology can also be used to give depth of experience to simulations and act as a decision arena in design processes. In the next round of courses, students will be able to work in the VPSL environment on campus with virtual production at the forefront of technology.

Research projects

Also in the research area of Virtual Production and related technology there have been progress. Here some projects that have been approved and are contributing to, and utilizing the VPSL.

DemoCreate – Creative power for a democratic society

- “DemoCreate”. DemoCreate aims to get more creative actors in the creative fields to be able to realize their ideas through specific project efforts outside the usual formats. Through the investment, actors, services and products in creative subjects, which Sweden is known for, get the opportunity to reach out on better terms than until now. VPSL is an important part of the investment, as project partners will be able to access this unique resource and associated expertise.

- More info: https://www.productdevelopment.se/democreate-2023/

RESIST – Regions for climate change resilience through Innovation, Science and Technology

- RESIST is a five-year project that has emerged from the need to make regions more resilient to climate change. The project will adopt a new practical framework in which climate adaptation pathways will be tested in four EU regions with different socioeconomic profiles: Southwest Finland, Central Denmark, Catalonia and Central Portugal. Each region will test adaptation solutions to five key climate challenges: floods, droughts, heatwaves, wildfires, and soil erosion, and will bring together civil society, business, policymakers and the research community to work towards its future resilience. Know-how and adaptation pathways will be transferred from the four demonstrator regions to eight twinned regions through mutual-learning activities and immersive digital twins.

- More info: https://www.productdevelopment.se/resist-regions-for-climate-change-resilience-through-innovation-science-and-technology-2023-2027/

RECS – Resilience in electricity & charging systems

- The project will investigate possible electrical systems for a transport system with passenger ferries in urban public transport. Investigate how a marine transport system can be integrated with energy storage and the power grid, and at the same time be flexible to withstand disturbances. This includes energy efficiency, resilience, charging and land infrastructure. The goal is to increase knowledge about system limitations, requirements for the transport system and the electricity infrastructure in order to maintain transport capacity in the event of disturbances. As well as requirements for flexibility in the transport system to function under different infrastructure conditions.

- More info: https://www.productdevelopment.se/recs-resilience-in-electricity-charging-systems-2024-2025/

PROSUCCO – PRO SUstainable Co-COnfiguration

- The PROSUCCO project focuses on supporting sustainable Co-configurability of High Value Low Volume (HVLV) products in the conceptual design phase. The HVLV industry entails complex, flexible processes encompassing consistent effort in engineering to order. The PROSUCCO project aims to support the development of HVLV products by developing innovative engineering design and systems engineering approaches to consistently reduce the ad-hoc development and engineering-to-order activities by focusing on modular and reusable design configurations. The increased modularity in design is expected to consistently save time and resources in the conceptual design stage as well as allow a more efficient and less expensive re-configuration process along the product and system lifecycle. The project is run in the context of cruise shipbuilding in close collaboration with Meyer Turku Shipyard, the University of Tampere, Nordic Element Oy, and Cometa Solution Oy. PDRL is responsible for creating and prototyping a multifactor optimization environment inspired by the Value Driven Design principles to support early conceptual design assessment.

- More info: https://www.productdevelopment.se/prosucco-pro-sustainable-co-configuration/

AXESS – Assessment in XR Environments for Sustainable Solutions

- The industry is challenged to comply with increasingly demanding societal and customer needs. Various stakeholders must be engaged throughout the development process. Models and simulations are used to assess new solutions and optimize current ones, foresee decisions’ implications, and make them explainable within the company and with customers. However, diversity in background, knowledge, and expectations among the stakeholders, raises the risk of misunderstandings in communicating values and tradeoffs, leading customers to hesitate when adopting innovative and sustainable solutions. Extended Reality (XR) is a promising problem solver to make the experience with solutions and visual data more accessible. The offer of new dedicated tools targeting the industry is increasing, leading to the rise of the industrial metaverse, an industrial digital twin environment. However, a knowledge gap in the industry and academia hinders this transformation. AXESS will make XR tools more accessible for the industry by providing experience with their use and development and exploring different case studies across diverse businesses. The project will deliver XR tools for customer needs and solutions assessment, including their testing and validation. Knowledge transfer and exchange among the academic and industrial partners will facilitate this process, preparing employees and stakeholders for rapid integration of XR in the companies’ practices and operations in the future years.

- More info: https://www.productdevelopment.se/axess-assessment-in-xr-environments-for-sustainable-solutions-2024-2027/

- VPSL is also part of the NATO DIANA test center that has been recommended for Karlskrona.

For more info

- On Virtual Production Studio Lab (https://www.productdevelopment.se/virtual-production-studio-lab/); Professor Tobias Larsson and Postdoc Ryan Ruvald.

- On VP education; lecturer Andrea Nordwall.

- Visual Effects; Anton Johansson, Istudios Visuals.

- Movie production in Blekinge; Henrik JP Åkesson Ruben, Karlskrona Kommun

1 thought on “Depeening the Virtual Production skills at BTH!”

Comments are closed.