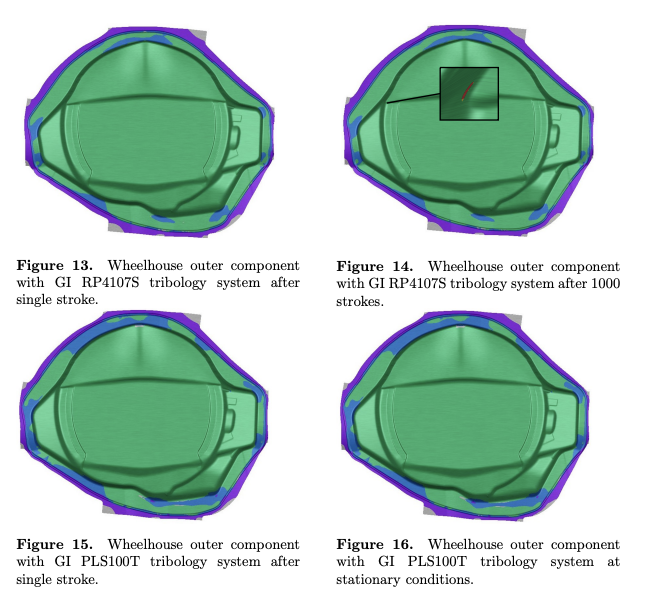

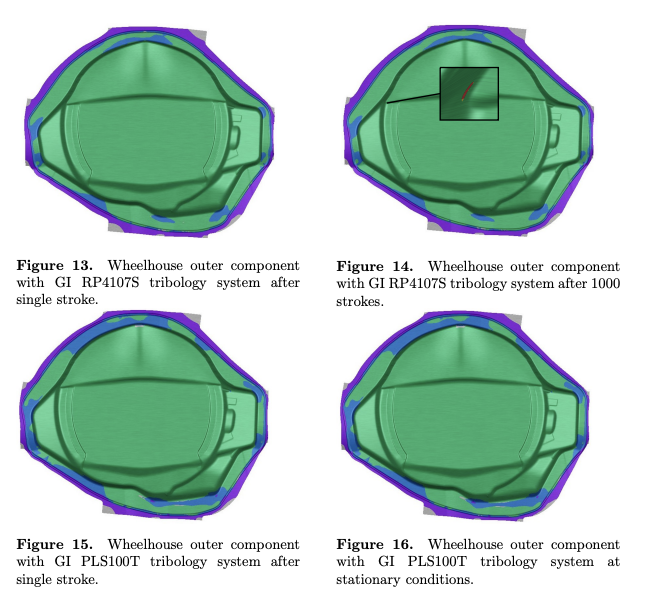

Abstract During the running production of automotive body components drifts in theprocess window is seen causing problems with non-conforming parts. Up until now, these driftshave been counter-acted based on the […]

Read More

Abstract During the running production of automotive body components drifts in theprocess window is seen causing problems with non-conforming parts. Up until now, these driftshave been counter-acted based on the […]

Read More

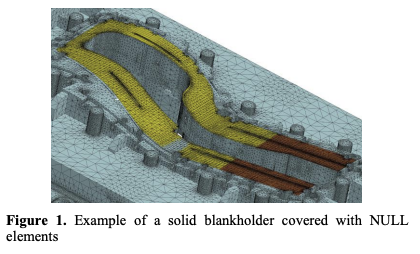

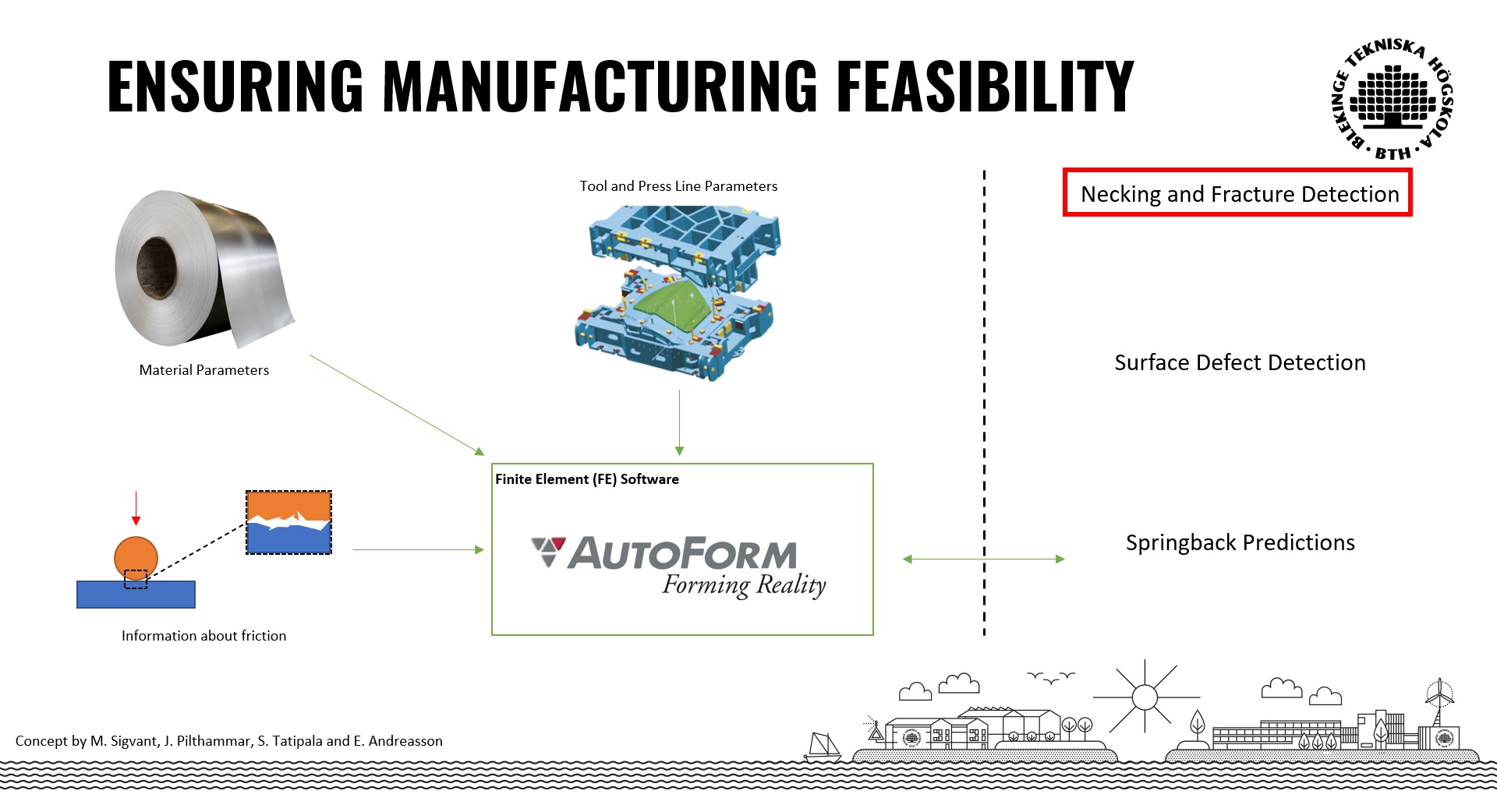

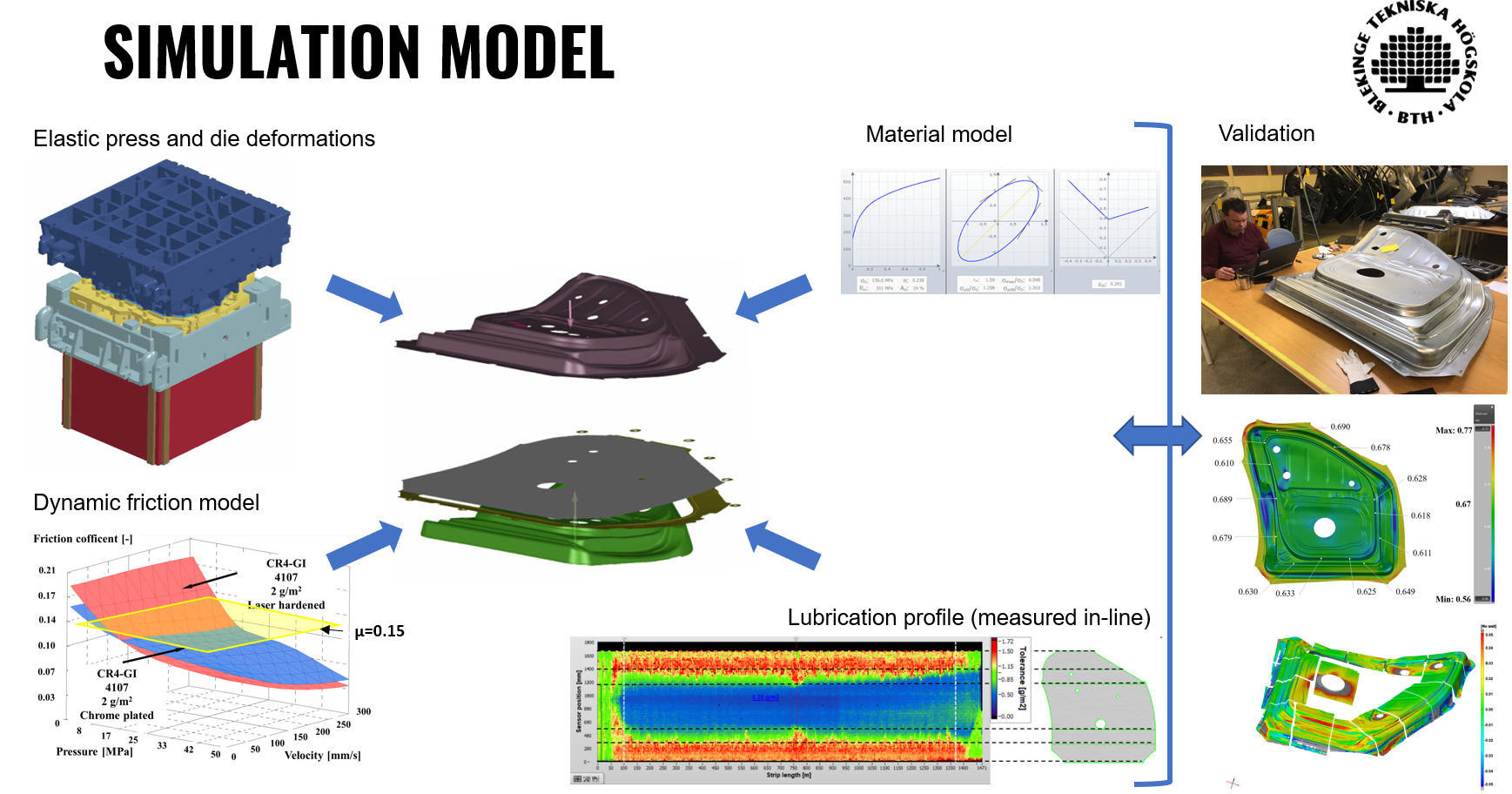

ABSTRACT Sheet metal forming (SMF) simulations are traditionally carried out with rigid active forming surfaces. This means that the elasticity and dynamics of presses and die structures are ignored. The […]

Read More

ABSTRACT In sheet metal stamping, the occurrence of strain localization in a deformed sheet is considered a failure. As so, sheet metal’s formability is conventionally evaluated using the Forming Limit […]

Read More

Monday afternoon Mats Sigvant (PhD, Technology Development, Volvo Cars and Adjunct Lecturer at Mechanical Engineering, BTH) held is trial lecture for appointment as Docent at BTH (Associate Professor). The title […]

Read More

Alexander Barlo presented his licentiate thesis entitled “Failure Prediction of Complex Load Cases in Sheet Metal Forming: Emphasis on Non-Linear Strain Paths, Stretch-Bending and Edge Effects” in front of an […]

Read More

The 2022 Techtank Conference was held Nov 30 2022 as an online event. The theme of the conference was “Smart Solutions for a Sustainable Production: – Applied methods and tools […]

Read More

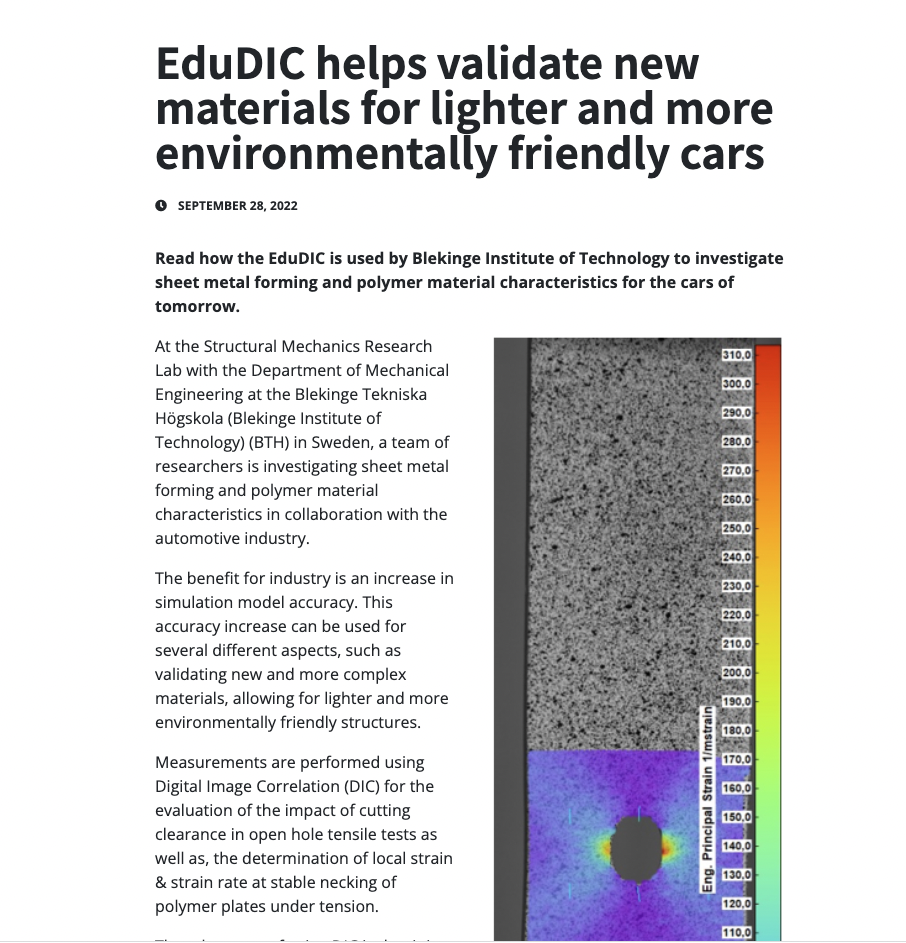

Alexander Barlo, PhD candidate with BTH Mechanical Engineering was featured in a piece by Dantec Dynamics on the EducDIC system used in sheet metal forming and polymer material characteristics for […]

Read More

Alexander Barlo is since early 2021 a PhD candidate in Mechanical Engineering at BTH. He is working with failure prediction in Sheet Metal Forming (SMF) Accurate failure prediction in Sheet […]

Read More

This postdoctoral position is linked to ongoing research projects at the Department of Mechanical Engineering within simulation of sheet metal forming. Research focus is to achieve a more accurate failure […]

Read More

Together with Volvo Cars (Olofström), Telenor Connexion and Blue Science Part as coordinator, a research and application project has been carried out within the “Test arena Blekinge” with the aim […]

Read More