Investigation of Temperature Impact on Friction Conditions in Running Production of Automotive Body Components

- Post by: Tobias Larsson

- 29th June 2024

- No Comment

Abstract

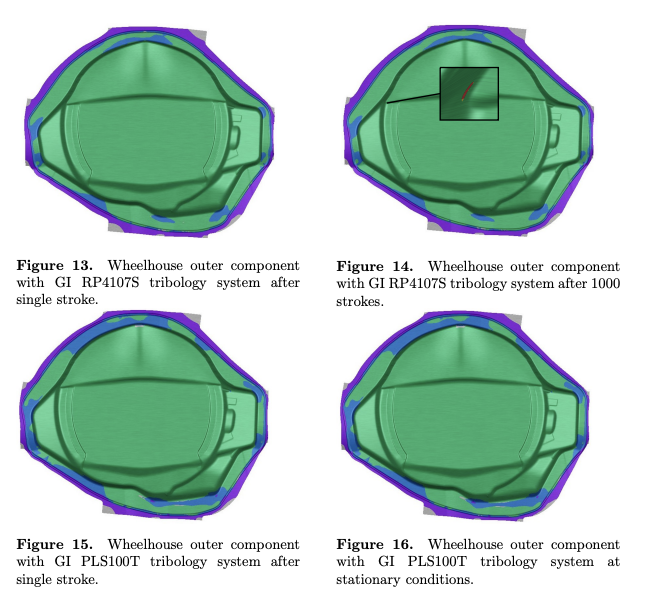

During the running production of automotive body components drifts in theprocess window is seen causing problems with non-conforming parts. Up until now, these driftshave been counter-acted based on the knowledge and experience of the press line operators.This experience-based process control will however become more troublesome in the future asrecycled material grades will undoubtedly present larger in-coil variations in material parametersand effect also the friction conditions from component to component.The following study will present two cases from production of the Volvo XC60. For thetwo cases, the initial simulations made for the components showed a safe part, but duringrunning production failure occurred suspected to be due to temperature effects in the tribologysystem. The study will furthermore present updated simulations considering developing thermaleffects to replicate the failures, as well as present both standard and thermal simulations of theadjustments made in production.

Keywords

–

Reference

A Barlo et al 2024 IOP Conf. Ser.: Mater. Sci. Eng. 1307 012004

Download

Project

- PREDICT | 2020-2024

- I-Stamp – Intelligent and sustainable stamping processes using hybrid control strategies together with process monitoring | 2021-2024