Tillsammans med Volvo Cars (Olofström), Telenor Connexion och Blue Science Part som koordinator har ett forsknings- och tillämpningsprojekt utförts inom “Test-arena Blekinge” med syfte att omvandla teori till praktisk tillämpbar […]

Read More

Tillsammans med Volvo Cars (Olofström), Telenor Connexion och Blue Science Part som koordinator har ett forsknings- och tillämpningsprojekt utförts inom “Test-arena Blekinge” med syfte att omvandla teori till praktisk tillämpbar […]

Read More

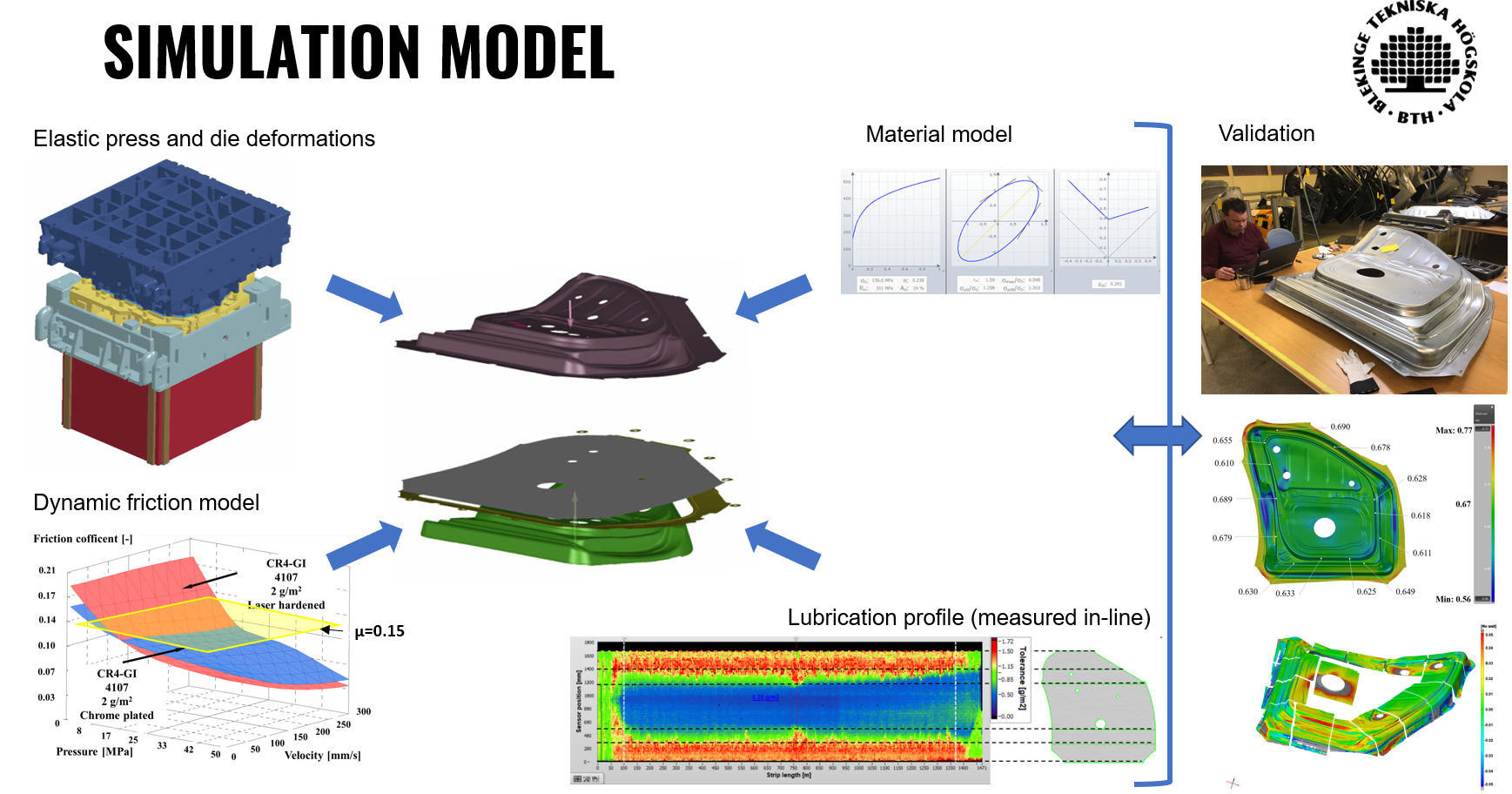

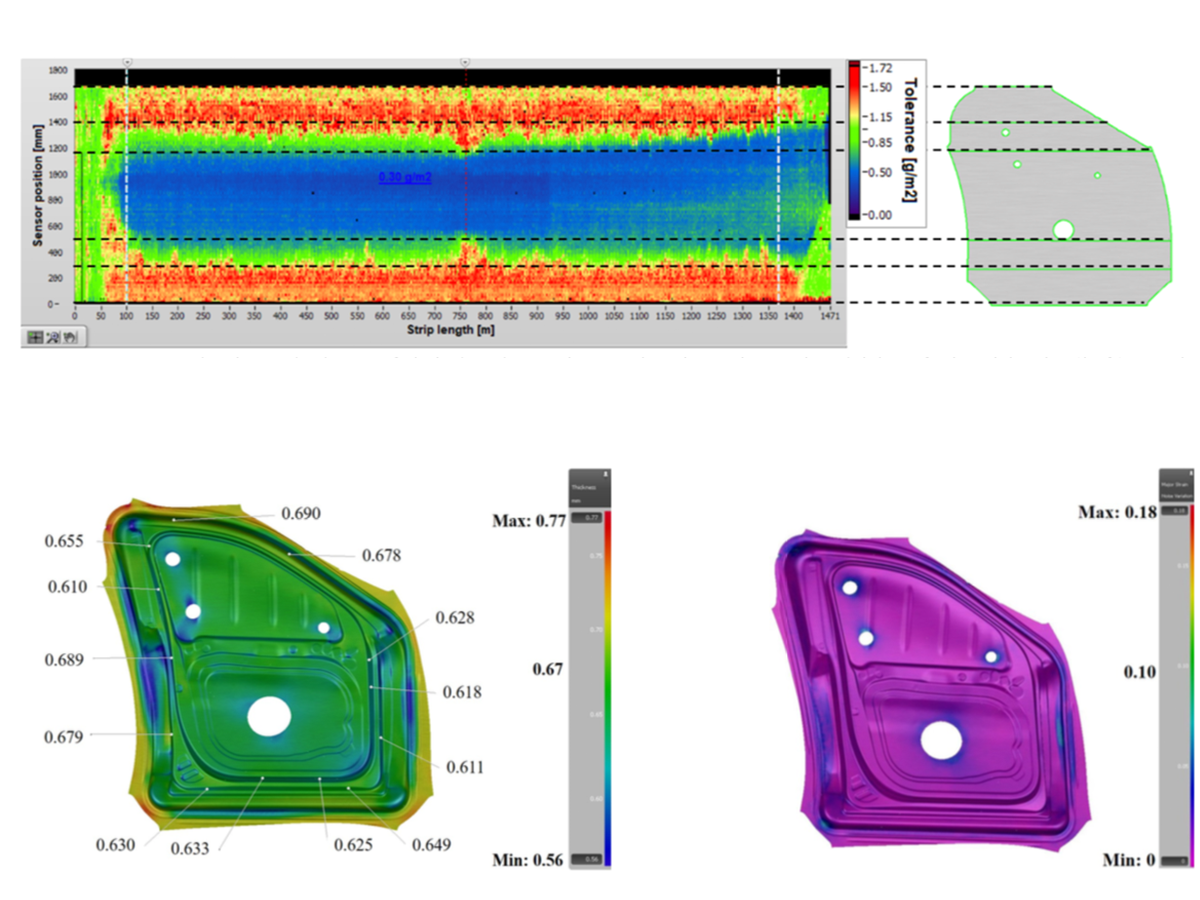

Abstract The ability to predict and control the outcome of the sheet metal forming process demands holistic knowledge of the product/process parameter influences and their contribution in shaping the output […]

Read More

Sravan Tatipala presented his licentiate thesis entitled “Sheet metal forming in the era of industry 4.0: using data and simulations to improve understanding, predictability and performance” in front of an […]

Read More

ABSTRACT With growing demands on quality of produced parts, concepts like zero-defect manufacturing are gaining increasing importance. As one of the means to achieve this, industries strive to attain the […]

Read More

ABSTRACT The ability to control quality of a part is gaining increased importance with desires to achieve zero-defect manufacturing. Two significant factors affecting process robustness in production of deep drawn […]

Read More

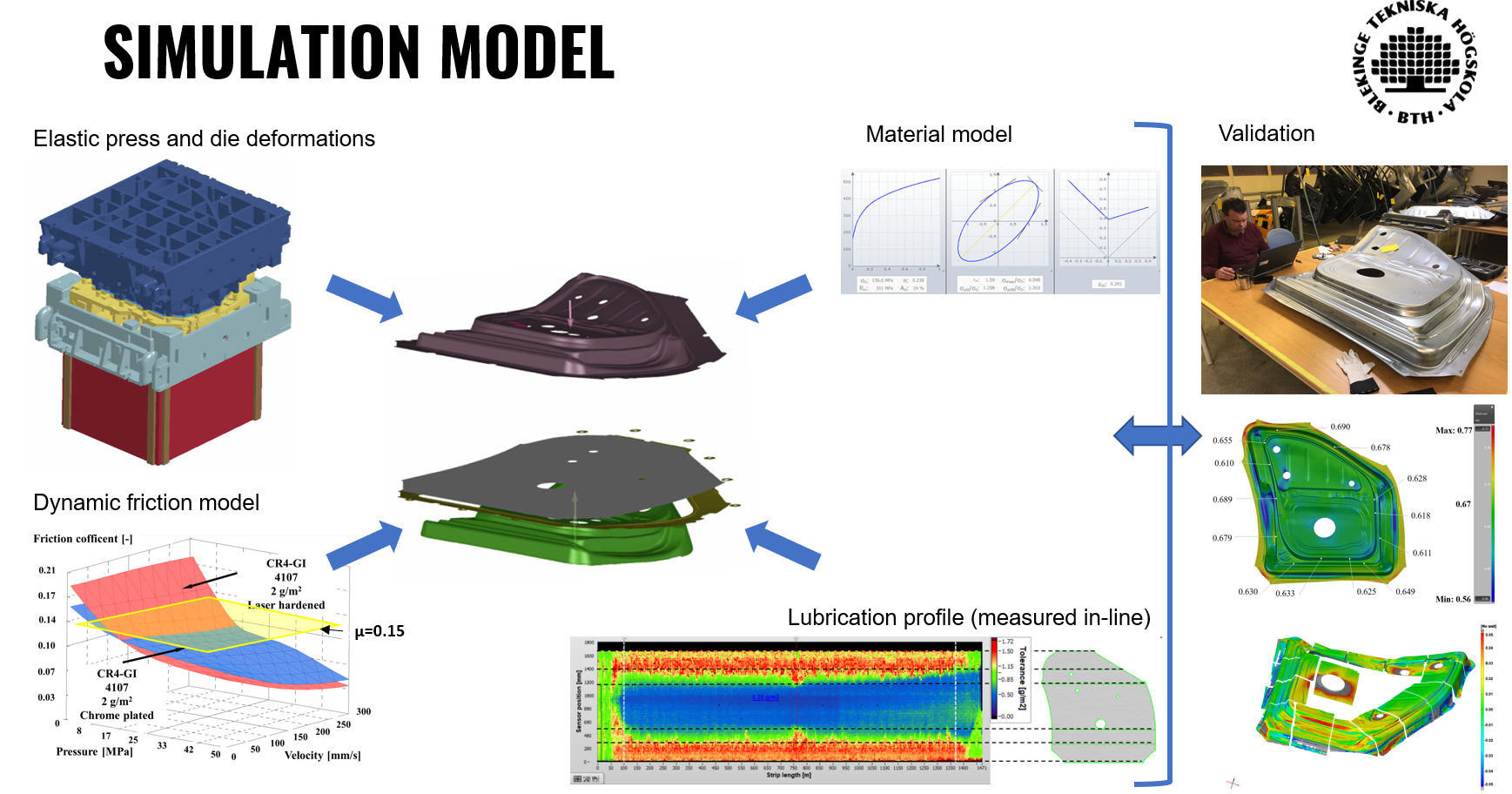

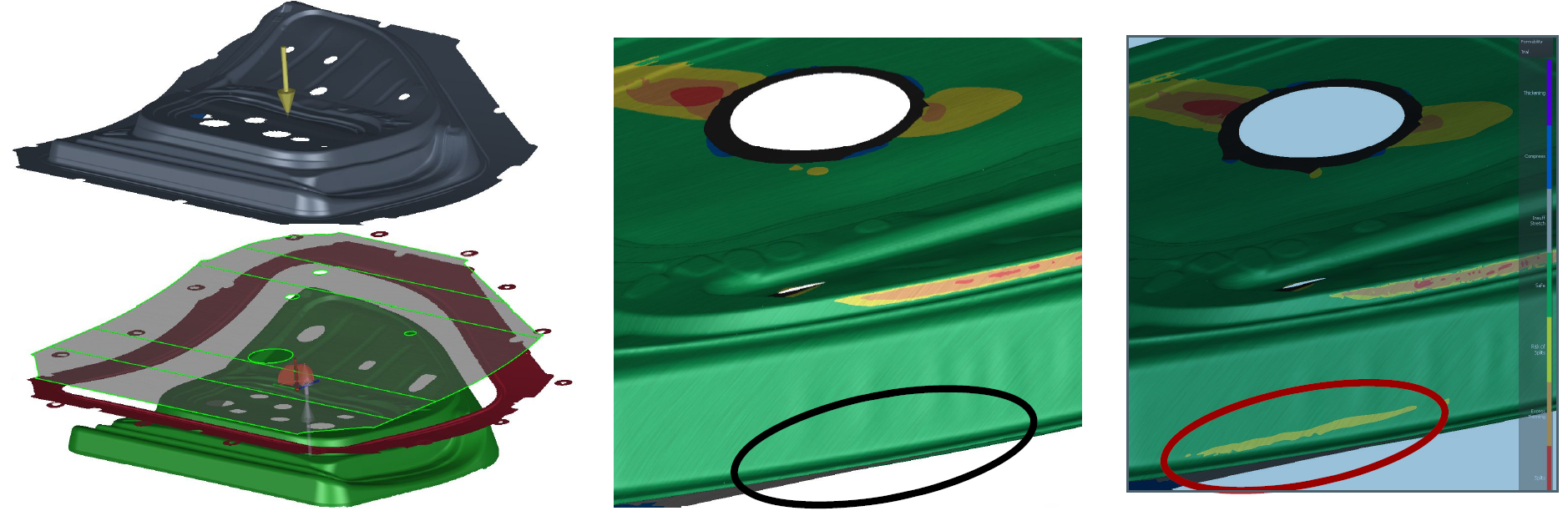

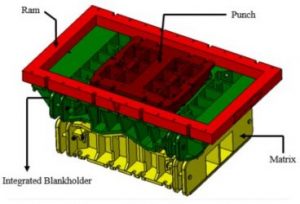

On December 14 Johan Pilthammar, Industrial PhD Candidate of Volvo Cars, presented and successfully discussed his licentiate thesis in Mechanical Engineering. The title of his thesis is “Elastic Press and Die Deformations in Sheet Metal Forming Simulations.”

Read More

ABSTRACT Never before has the car industry been as challenging, interesting, and demanding as it is today. New and advanced techniques are being continuously introduced, which has led to increasing […]

Read More

ABSTRACT Reliable design of stamping dies is desired for efficient and safe production. The design of stamping dies are today mostly based on casting feasibility, although it can also be […]

Read More