Research Spotlight; Alexander Barlo

- Post by: Tobias Larsson

- 22nd December 2021

- No Comment

Alexander Barlo is since early 2021 a PhD candidate in Mechanical Engineering at BTH. He is working with failure prediction in Sheet Metal Forming (SMF)

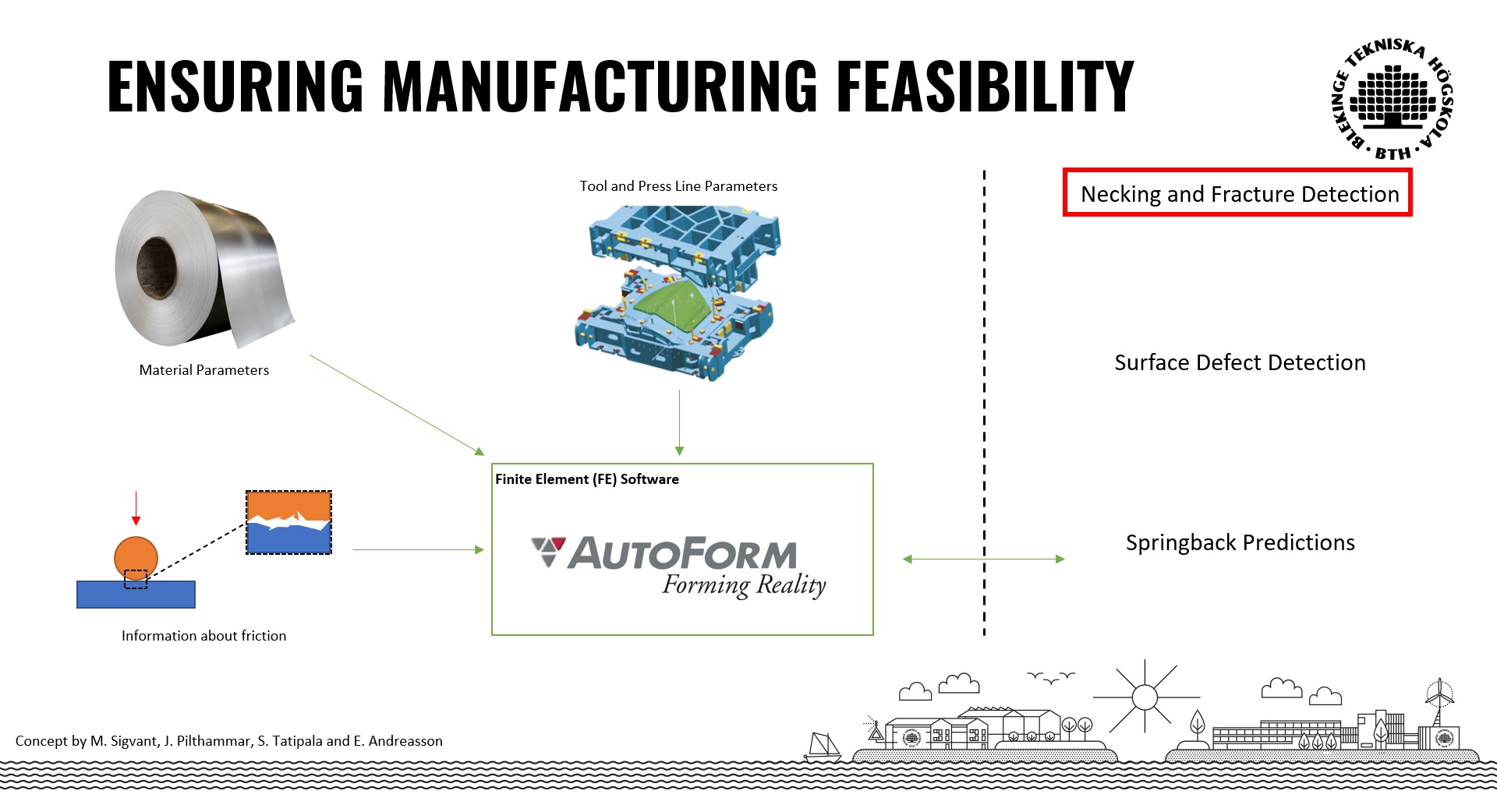

Accurate failure prediction in Sheet Metal Forming (SMF) is a core task for all Computer Aided Engineering (CAE) departments within e.g., the automotive industry. Simulation based failure prediction of the SMF process is one of the main arguments for investing in new tools and push sheet metal products to the production lines.

Why are you doing this research?

The topic of Sheet Metal Forming is something that has been interesting me since early on in my Bachelor degree. Throughout me B.Sc. and M.Sc. it has been a topic I have revisited several times and my thesis was in collaboration with Volvo Cars in Olofström on Failure Prediction. What interests me about the field of failure prediction is the mechanics of the materials, and the ability to predict if a component is manufacturable or not.

What is the benefit for industry taking part?

The benefit for industry is an increase in simulation model accuracy. This accuracy increase can be used for several different aspects, such as validating new and more complex materials, allowing for lighter and more environmentally friendly structures. On the other hand, an increase in simulation model accuracy will also help the industry taking a step towards Industry 4.0 with a digital twin as part of their production setup. This step can have several benefits including the ability to better predict maintenance needs for heavy machinery in the press shops.

What is your driving force as a PhD candidate?

For me the driving force as a PhD candidate is to be working on the very edge of what we know today, and be able to explore new and uncharted territory. This I am able to do at BTH with some of the large industry influences in Sheet Metal Forming in Europe.

Research poster

Video presentation

Projects

Publications

- Diva link…