Abstract During the running production of automotive body components drifts in theprocess window is seen causing problems with non-conforming parts. Up until now, these driftshave been counter-acted based on the […]

Read More

Abstract During the running production of automotive body components drifts in theprocess window is seen causing problems with non-conforming parts. Up until now, these driftshave been counter-acted based on the […]

Read More

Alexander Barlo presented his licentiate thesis entitled “Failure Prediction of Complex Load Cases in Sheet Metal Forming: Emphasis on Non-Linear Strain Paths, Stretch-Bending and Edge Effects” in front of an […]

Read More

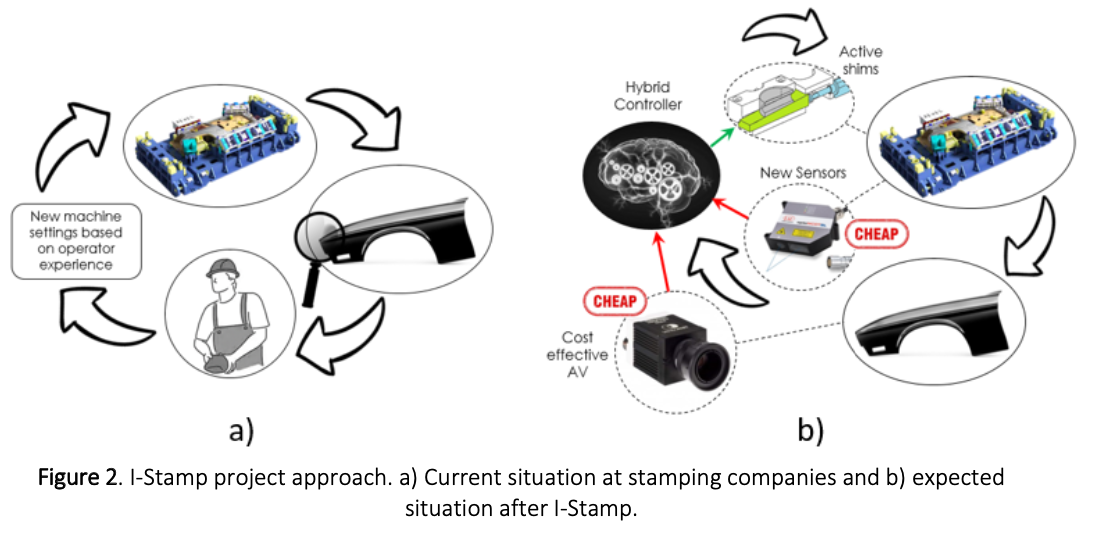

The partners of I-STAMP project met in Mondragon Spain between 6th and 7th February to discuss project progress and exchange learnings. I-STAMp project aims to develop cost-effective and affordable actuators […]

Read More

September 14 the KKS profile Model Driven Developmennt and Decision Support MD3S that has been running since 2013 (6 year KKS profile & 3 year profile+) held a final seminar […]

Read More

The machine tool investment for stamping (presses and tools) is cost intensive in the automotive industry. The machine tool investment for stamping (presses and tools) is cost intensive in the […]

Read More

8th of October was the Academic Ceremony at BTH with promotion of PhD’s and installation of professors among other things on the agenda. From Product Development Research Lab and the […]

Read More

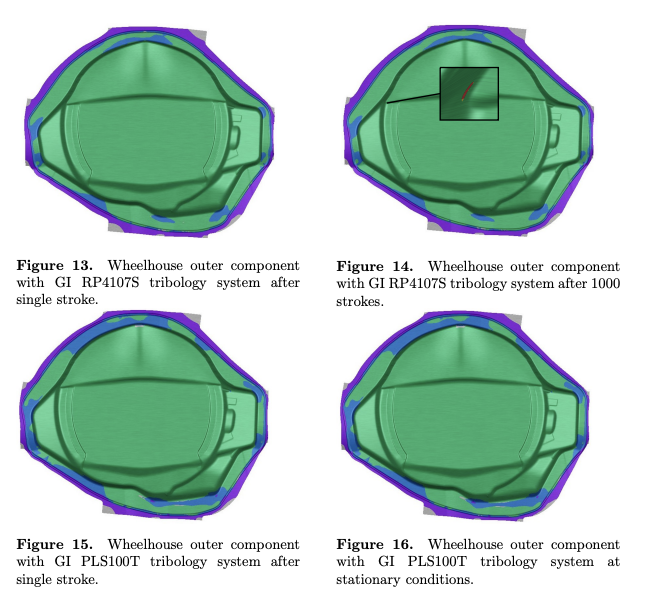

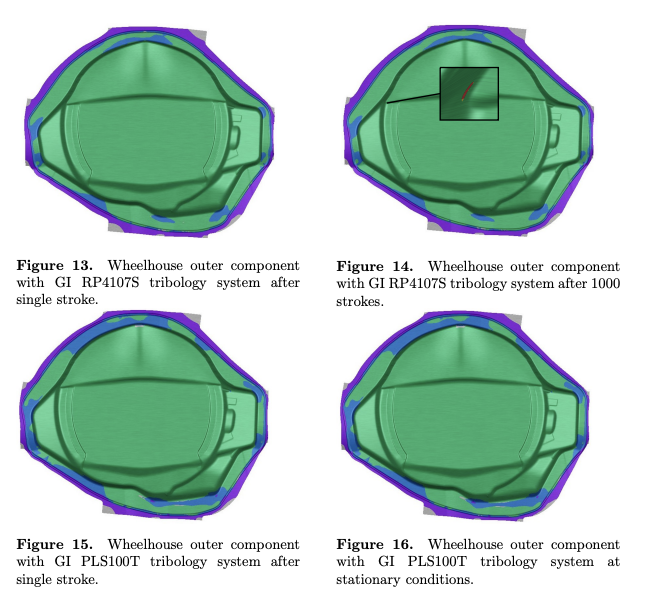

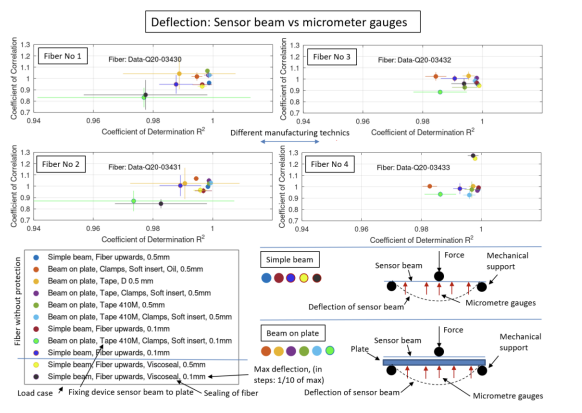

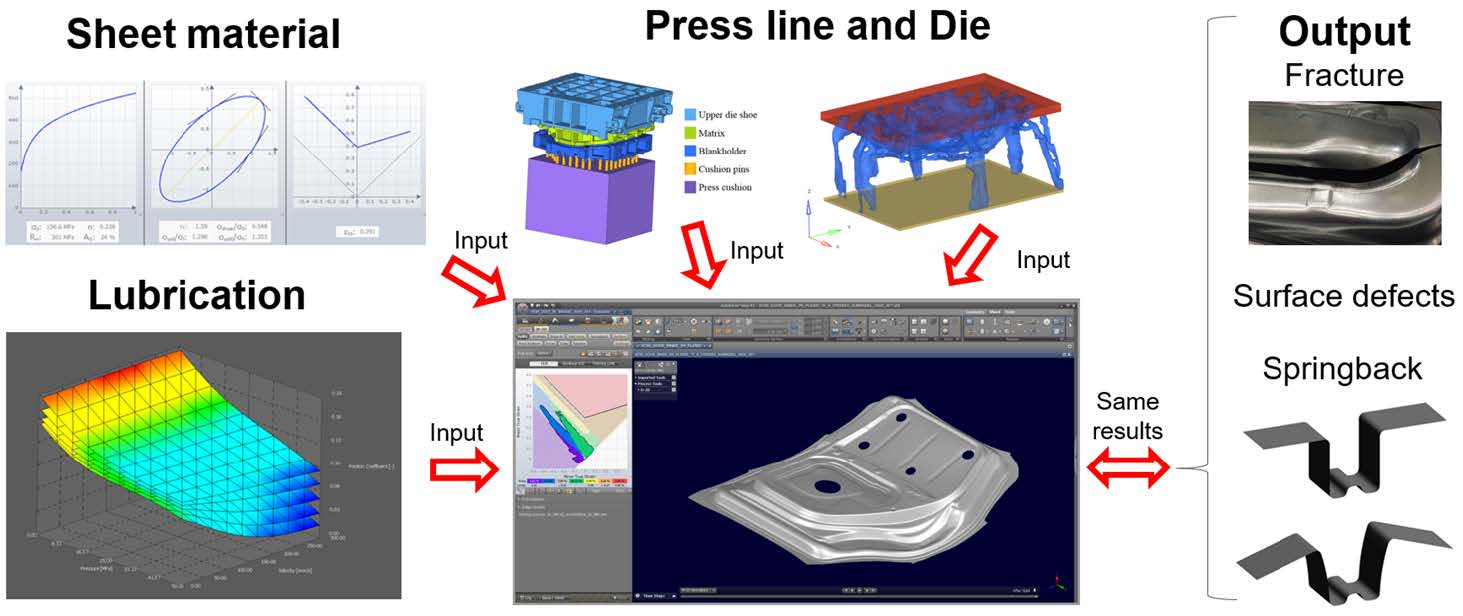

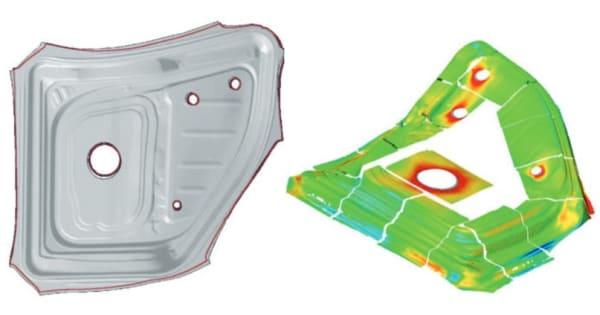

Abstract Cost and time for die tryout are significant within the car industry, and elastic deflections of dies and presses are most commonly not considered during the virtual die design […]

Read More

WHO ARE YOU AND WHAT IS YOUR BACKGROUND? My name is Johan Pilthammar and I live in Hällevik, Sölvesborg, with my wife and four children. I work as a research […]

Read More

Abstract Ability to predict and control involved parameters and hence the outcome of sheet metal forming processes demand holistic knowledge of the product/-process parameter influences and their contribution in shaping […]

Read More

Concluding remarks and results PREDICT has generated results and tools that are used to increase reliability of failure prediction of sheet metal forming simulation in finite element models (FE-model). The […]

Read More