Congratulations Sravan Tatipala, Licentiate in Mechanical Engineering!

- Post by: Tobias Larsson

- 20th December 2019

- 3 Comments

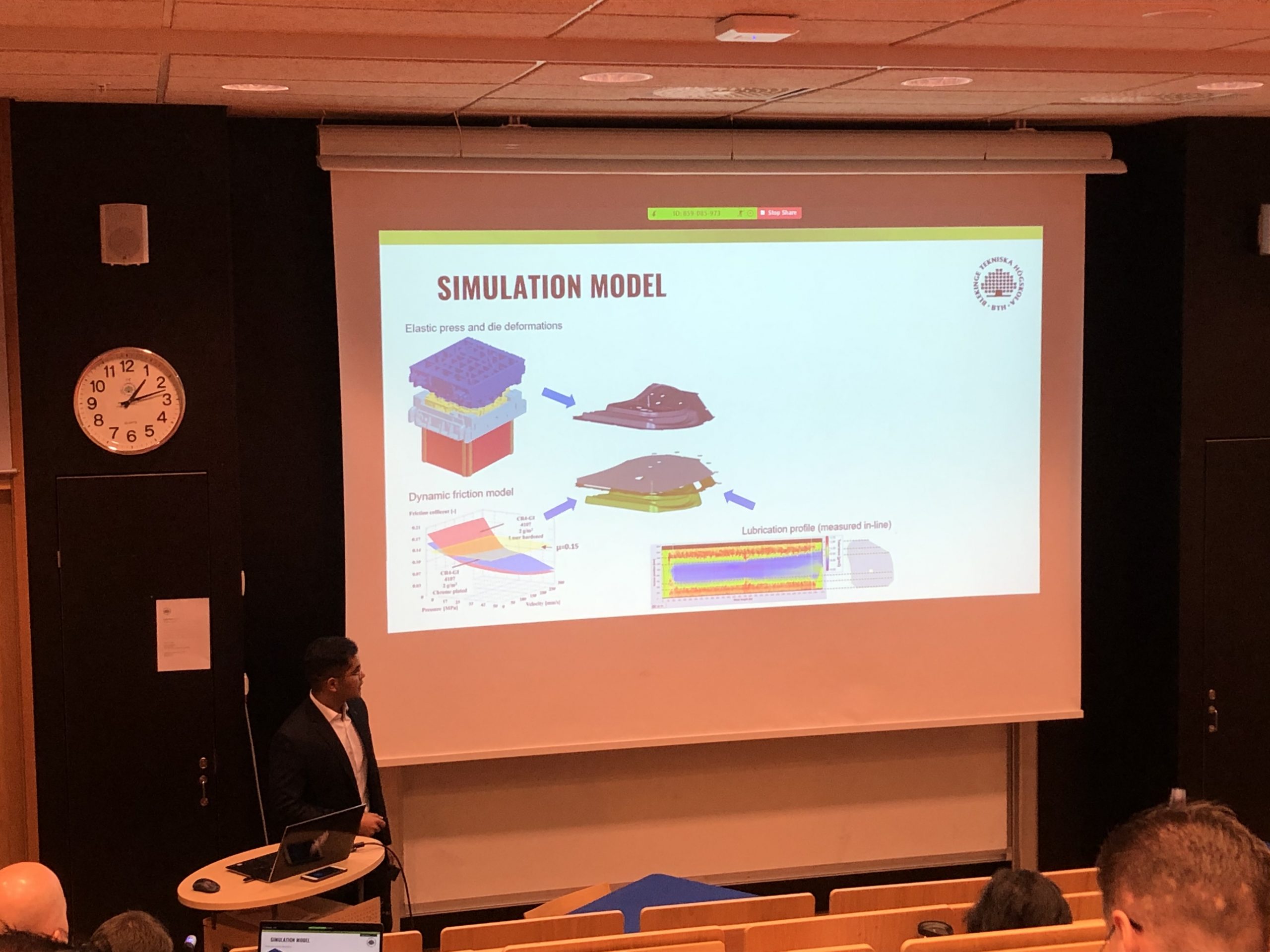

Sravan Tatipala presented his licentiate thesis entitled “Sheet metal forming in the era of industry 4.0: using data and simulations to improve understanding, predictability and performance” in front of an interested audience both present, and via online, on Friday afternoon.

Sravan presented the context and motivation for his research and then took the audience through research methodology and findings (thesis consists of a summary part and three individual research publications) and then landed in a summary of his findings.

Opponent for the day was the researcher Mehdi Tarkian of Linköping University. Mehdi went went deeper into details to press Sravan and enrich the knowledge around the material and in order to get a sense of how Sravan had approached the research and also on how conclusion where made.

At the end also the audience had the chance to ask questions on the research.

Examiner Professor Tobias Larsson then concluded by declaring that Sravan had passed the exam and achieved the licentiate degree.

Besides the examiner the supervisors of Sravan has been Assistant Professor Christian Johansson Askling and Assistant Professor Johan Wall.

Thesis abstract

A major issue within automotive Sheet Metal Forming (SMF) concerns ensuring desired output product quality and consistent process performance. This is fueled by complex physical phenomena, process fluctuations and complicated parameter correlations governing the dynamics of the production processes. The aim of the thesis is to provide a deeper understanding of the challenges and opportunities in this regard within automotive SMF. The research is conducted in collaboration with a global automotive manufacturer.

The research shows that systematic investigations using process simulation models allow exploration of the product-process parameter interdependencies and their influence on the output product quality. Furthermore, it is shown that incorporating in-line measured data within process simulation models enhance model prediction accuracy. In this regard, automating the data processing and model configuration tasks reduces the overall modelling effort.

However, utilization of results from process simulations within a production line requires real-time computational performance. The research hence proposes the use of reduced process models derived from process simulations in combination with production data, i.e. a hybrid data- and model-based approach. Such a hybrid approach would benefit process performance by capturing the deviations present in the real process while also incorporating the enhanced process knowledge derived from process simulations. Bringing monitoring and control realms within the production process to interact synergistically would facilitate the realization of such a hybrid approach.

The thesis presents a procedure for exploring the causal relationship between the product-process parameters and their influence on output product quality in addition to proposing an automated approach to process and configure in-line measured data for incorporation within process simulations. Furthermore, a framework for enhancing output product quality within automotive SMF is proposed. Based on the thesis findings, it can be concluded that in-line measured data combined with process simulations hold the potential to unveil the convoluted interplay of process parameters on the output product quality parameters.

Keywords: Modelling, Simulation, Industry 4.0, Sheet Metal Forming, Process Monitoring, Process Control, Automation, Finite Element Analysis, Smart Manufacturing, Mechanical Engineering

Video of the presentation

3 Comments on “Congratulations Sravan Tatipala, Licentiate in Mechanical Engineering!”

Comments are closed.