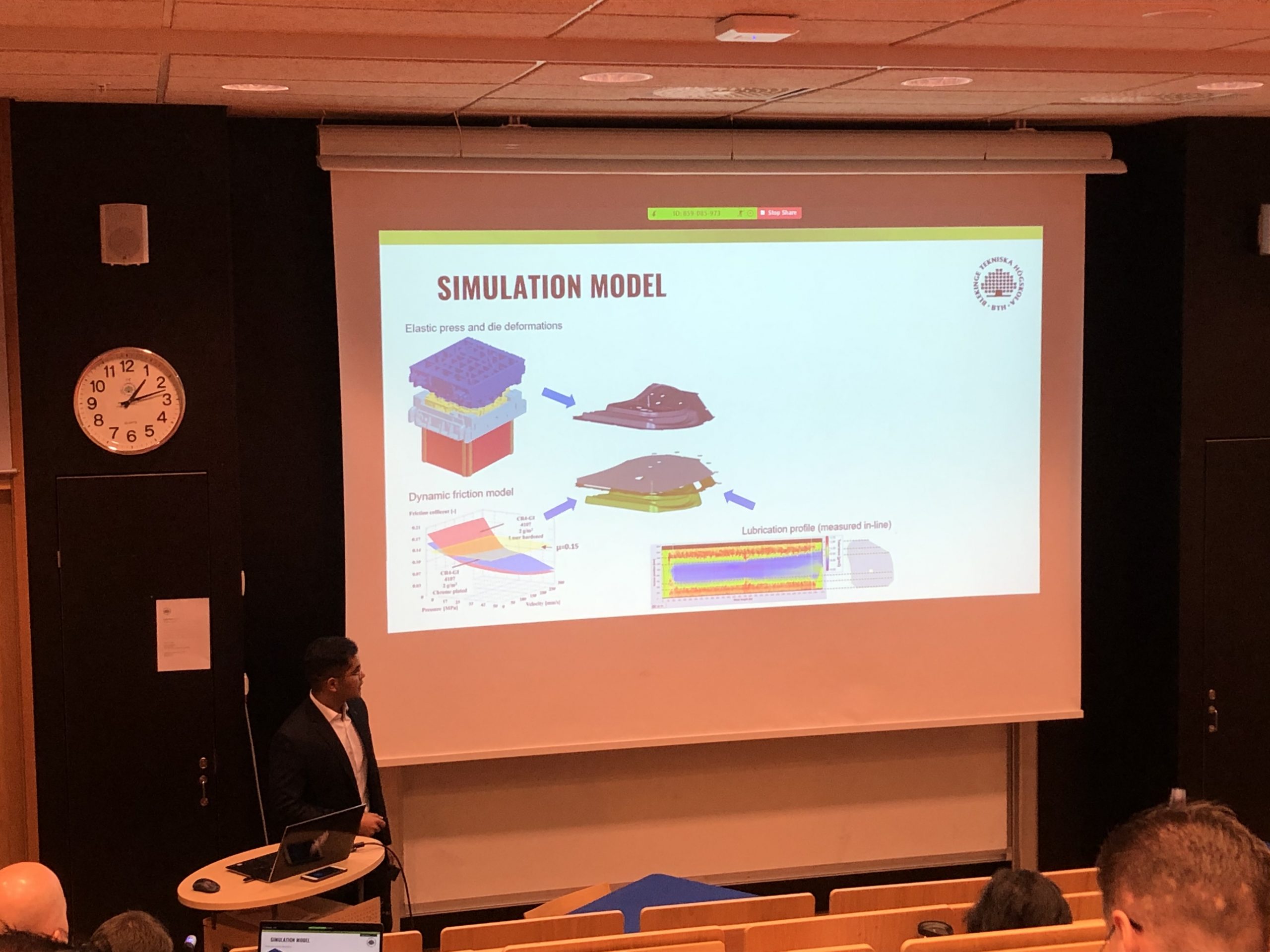

Monday afternoon Mats Sigvant (PhD, Technology Development, Volvo Cars and Adjunct Lecturer at Mechanical Engineering, BTH) held is trial lecture for appointment as Docent at BTH (Associate Professor). The title of the trial lecture was “Sheet Metal Forming Simulation: essential for the automotive industry and also an interesting academic challenge”. Some 50 people followed the […]

Read More

Congratulations on the “docent” Mats Sigvant!

- 14th June 2023

- No Comment