cx.Link for Volvo CE delivered at Stanford EXPE

- Post by: Christian Johansson

- 14th June 2016

- 4 Comments

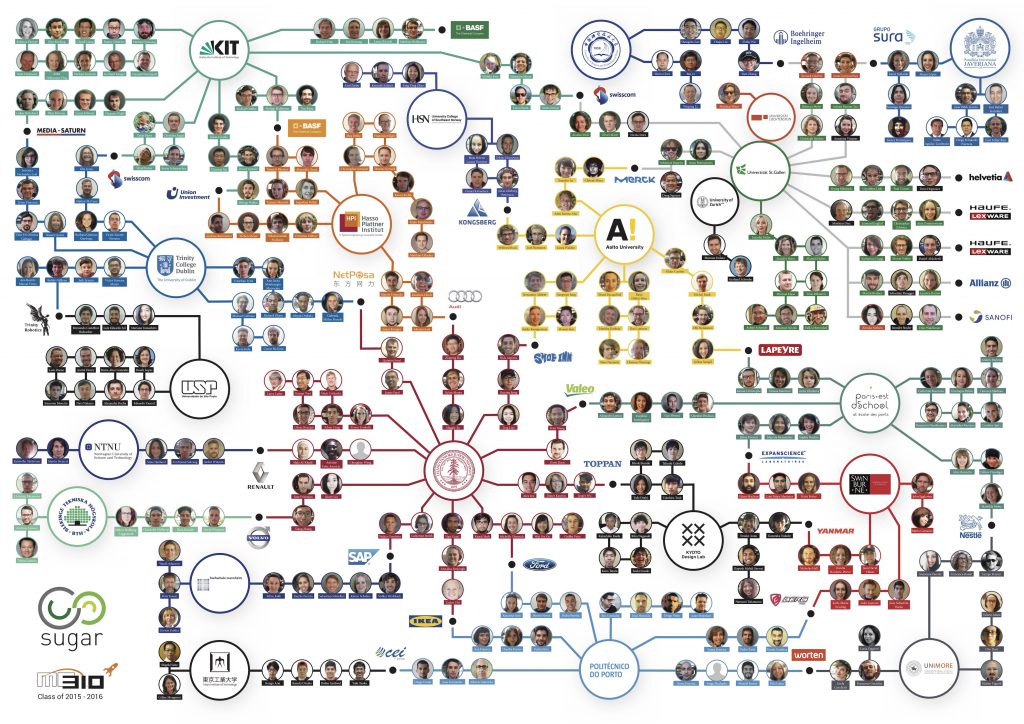

The Volvo CE Stanford ME310 project has been completed with the annual Stanford EXPE at Stanford University on June 2nd. Students from MSPI and Mechanical Engineering at BTH together with Mechanical Engineering counterparts at Stanford have presented their results for how autonomous machines should collaborate and build trust with their human collaborators at future construction sites.

The cx.Link

The cx.Link is a concept to support autonomous construction vehicles operating alongside human workers on major construction sites. As a leader in the construction industry, Volvo Construction Equipment (Volvo CE) are exploring concepts for running fully autonomous construction machines in aiming to increase productivity and to enhance safety for people in the sites. Even in this scenario there will be people on the site, maintaining machines and leading the operations. Therefore, the aim of the project is to create a system that will enable efficient communication between human workers and automated machines and thus such a system will increase safety and foster trust between the human workers and machines.

Jenny Elfsberg, Director Emerging Technologies, and Martin Frank, Specialist Intelligent Machines, are the liaisons from Volvo Construction Equipment, responsible for the project and the challenge the students begin with. “We want to explore how we can build trust between semi- and fully automated machines and humans. The best way is to use fresh, unspoiled engineering students to go crazy with prototypes,” says Martin Frank, who has been the coach from Volvo CE throughout the year.

“We started with a very open prompt with the design challenge, then they went out on needfinding, interviewing, observing – watching and listening to understand what solution is needed,” Martin continues.

Christian Johansson has been the faculty responsible for the project from the BTH side; “It’s been a really interesting project this year and a very good outcome. From a process perspective they have been doing a good job and my job has been mainly to allow the students to trust the process and let them work things out, basically mainly being supportive in their decisions. Some push here and there may be needed, but this year it’s been less of that, basically just ensuring that things are going smoothly and that the corporate partner is aligned with where we’re going.”

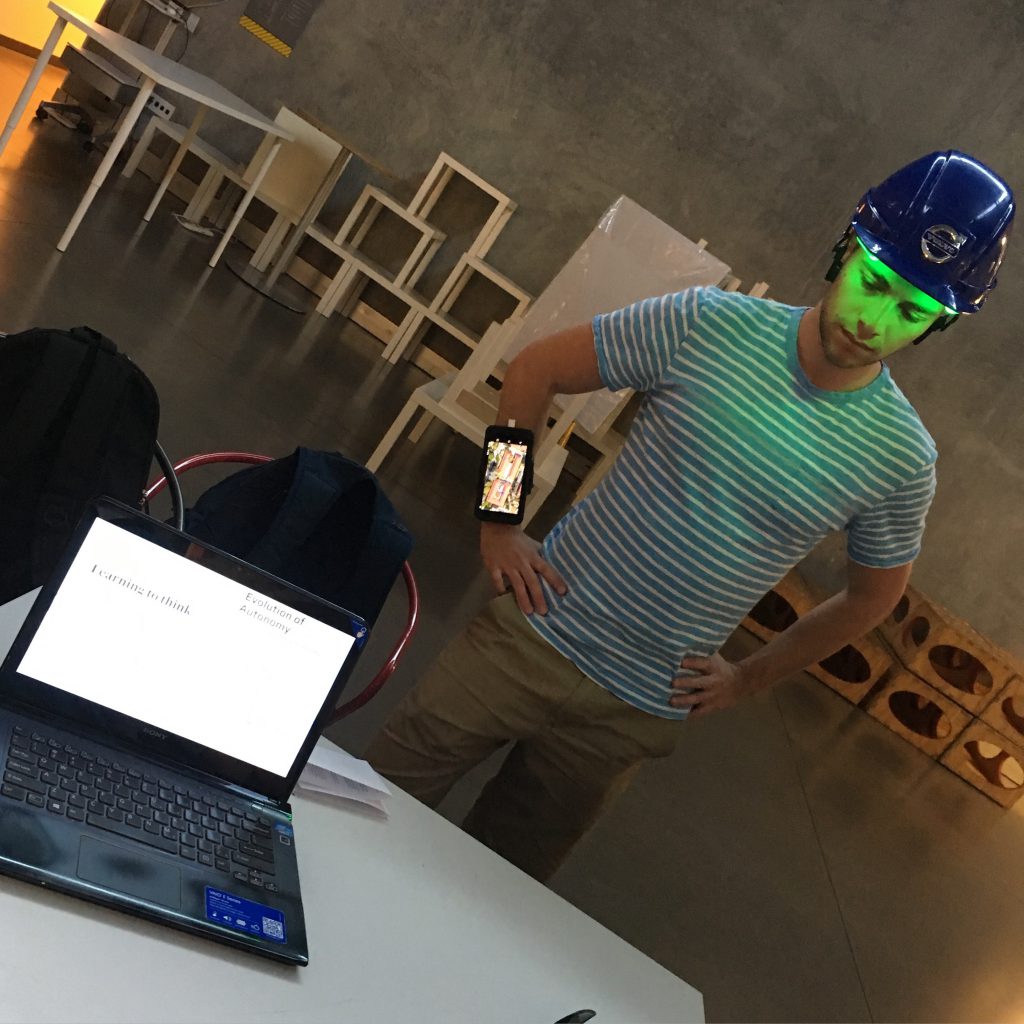

The system consists of a command center, smart hard-hat, machine pod and a wrist mounted display. The command center monitors the site for potential collisions. An alert is sent to the affected worker if a dangerous scenario is detected. The alert changes the color status of workers hard hat as well as the beacon light of the machine. The machine pod integrates today’s machines into a connected system, by transmitting location and position data. The beacon light conveys the current status of the machine. The hard-hat system is made up of an integrated bone conduction headset and light indicator. This provides workers with reliable audio and visual communication. The display provides workers with machine trajectories and intentions in real time. The display serves as a platform that enables workers to interact with machines, and provides workers with insight into the autonomous systems knowledge.

More detailed information and VR videos about the cx.Link solution can be found at the project website: http://www.me310volvoce2016.com/.

More on the ME310 2015/16 project here.

About ME310

The ME310 course at Stanford University is a three-quarter global design course starting in October and finishing at the EXPE event in June. The course features ten corporate-sponsored projects that all have global partner universities from around the world. For the last four years, mechanical engineering at BTH have been the only Swedish participants. Sponsors include major global brands, such as Volvo Construction Equipment, the Volkswagen Group, Renault, and SAP to name a few.

The course projects start in October with a global kick-off where the global team members as well as the corporate liaisons gather the teams in Stanford. Here they are handed their initial prompt by the sponsor and they also spend effort to build a good team spirit, which will enable effective collaboration over the coming months when they are geographically dispersed. “It’s important at the kickoff to make sure that they become one team and that they’re off to a flying start,” says Jenny Elfsberg.

The curriculum for the course is Design Thinking, depicting an entrepreneurial approach to design with much emphasis of prototyping as an approach to open-ended ill-defined problems where the students make extensive needfinding to define the problems. This is the same as the core curriculum for the MSPI program at BTH, which means that our students are somewhat familiar with the approach to design that is practiced.

“It’s generally a very good experience for students to have been working in global teams. Also, working with project where sponsors are very motivated in supporting the team is also important. They are required to follow through their projects until final prototype and show something, hopefully, captivating at EXPE,” says Christian.

An important credo is to preserve ambiguity for an extended part of the design process, with the strong belief that innovation is not a linear path known beforehand for the students. The students go through numerous iterations of prototyping and frequently venture into the field of the specific problem they are addressing.

Martin stressed that for the Volvo project it was “important to get the students out into the dirt and see how things are going on for real in a site. You can only find so much reading off the Internet, but there are so many subtle things going on at a site that you need to see with your own eyes.”

Final solutions are often highly developed mechanical and mechatronic systems and associated services, which are well-rooted in user needs to address these ill-defined problems. These are then unveiled at the EXPE at the end of the academic year. In attendance we usually find faculty all over the world, corporate liaisons, and also a fair share of other interested parties who wants to review both the results and the engineering talent at work.

On what happens next, Martin stresses that the knowledge will be shared within Volvo CE and that some of the findings can be applied in other projects being initiated. “This is also an excellent opportunity for us to learn more about the design thinking process and to see how the prototyping iterations can be applied to drive innovation much earlier with the rougher prototypes.”

“- ME310 Global Design Innovation and the Design Thinking approach is proving itself to be a valuable experience for both students and partners. For BTH students to be able to collaborate “in real life” with one of our research partners, and also with prestigious Stanford University, is simply a great experience. Challenging, but also rewarding”, says Professor Tobias Larsson of BTH Mechanical Engineering.

Previous years BTH/Stanford projects here.

Videos

Interviews with the students about their experience from working in the project:

Interview with David Winqvist (in Swedish) about his experience from working in the project:

Interviews with coaches Martin Frank (Specialist Intelligent Machines, Volvo CE) and Christian Johansson (Senior Lecturer, BTH) about their experiences in supporting the students:

Slideshow about EXPE 2016 for the Volvo CE team:

Interview with Hillevi Hallberg Lyggemark:

Another interview with David:

Also, d.School in Paris has put together this short video from the EXPE:

More pictures

4 Comments on “cx.Link for Volvo CE delivered at Stanford EXPE”

Comments are closed.