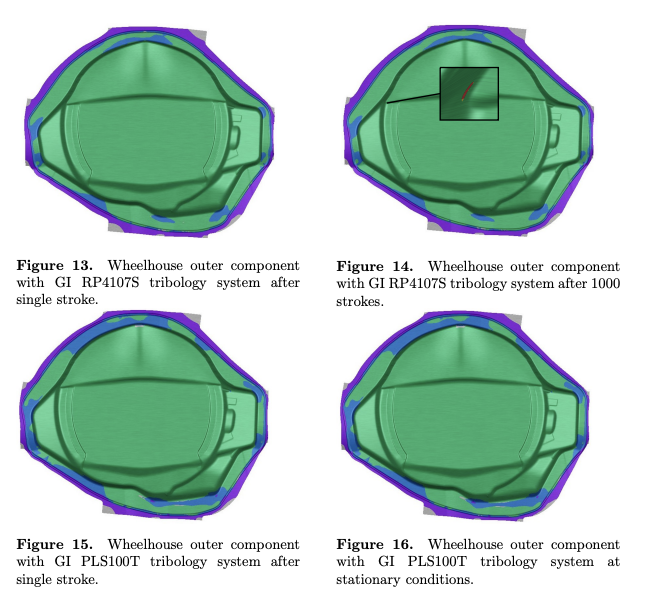

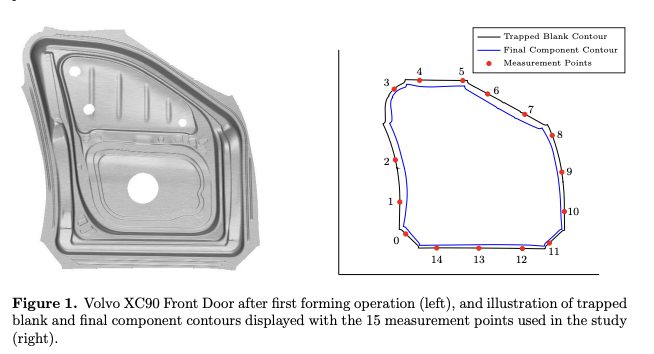

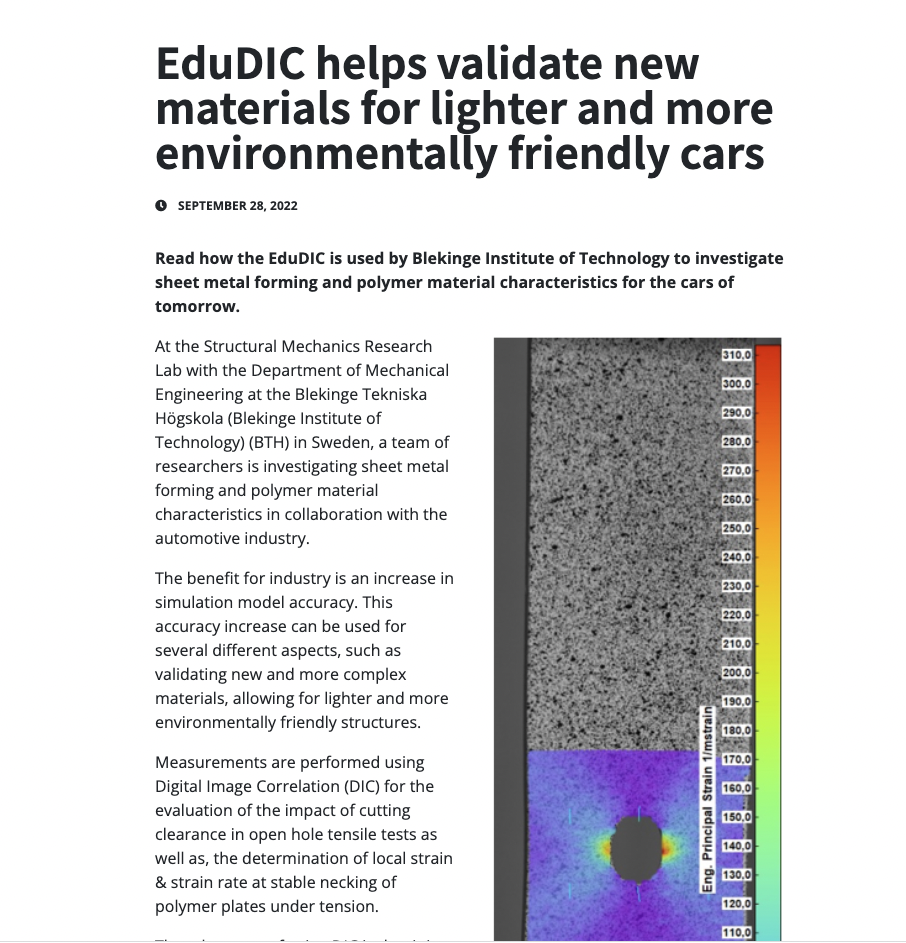

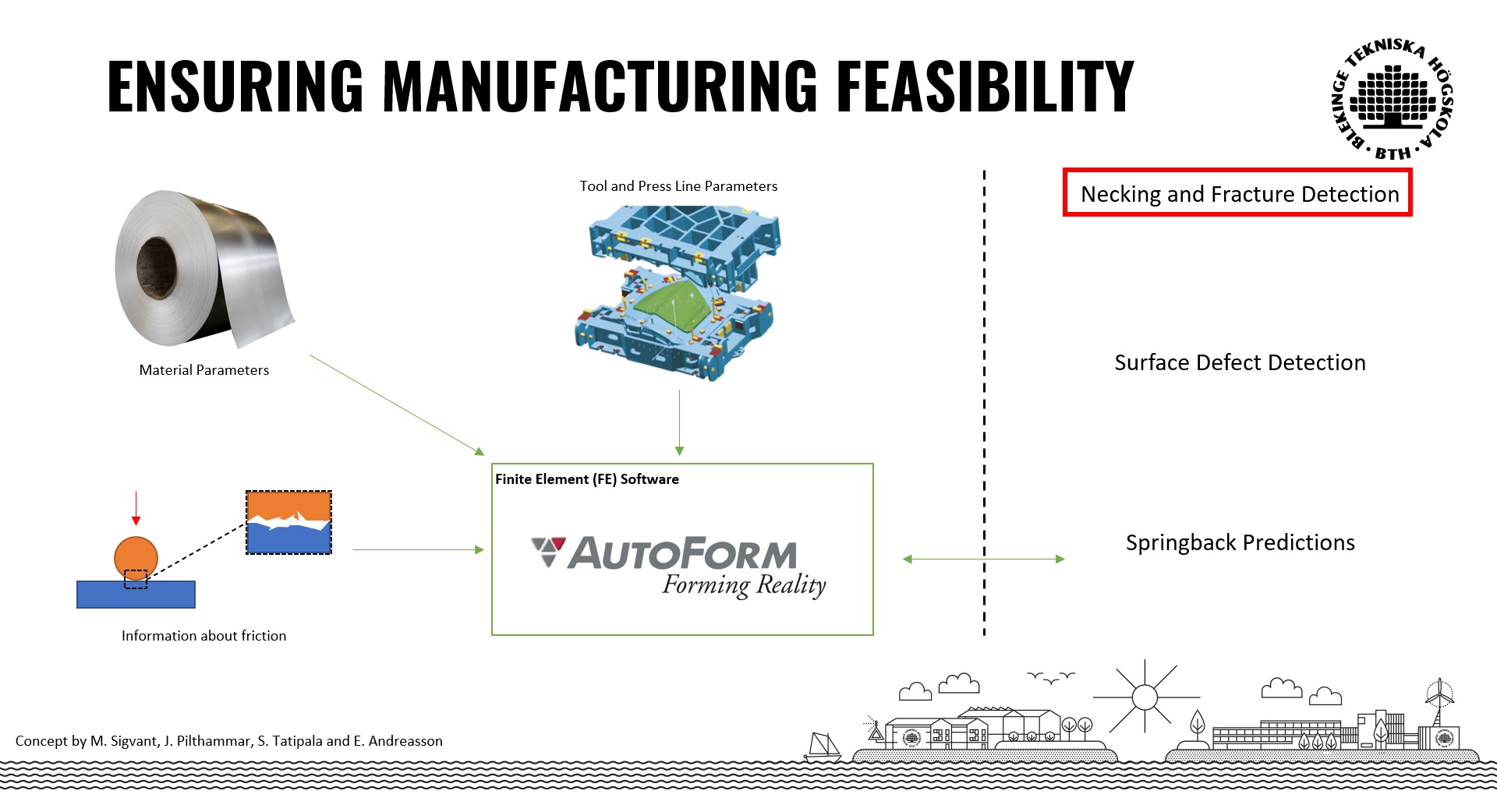

Abstract During the running production of automotive body components drifts in theprocess window is seen causing problems with non-conforming parts. Up until now, these driftshave been counter-acted based on the knowledge and experience of the press line operators.This experience-based process control will however become more troublesome in the future asrecycled material grades will undoubtedly present […]

Read More