Influence of Patterns on Mechanical Properties of Ultrasonically Welded Joints in Copper Substrate and Wire

- Post by: Tobias Larsson

- 9th March 2024

- No Comment

Abstract

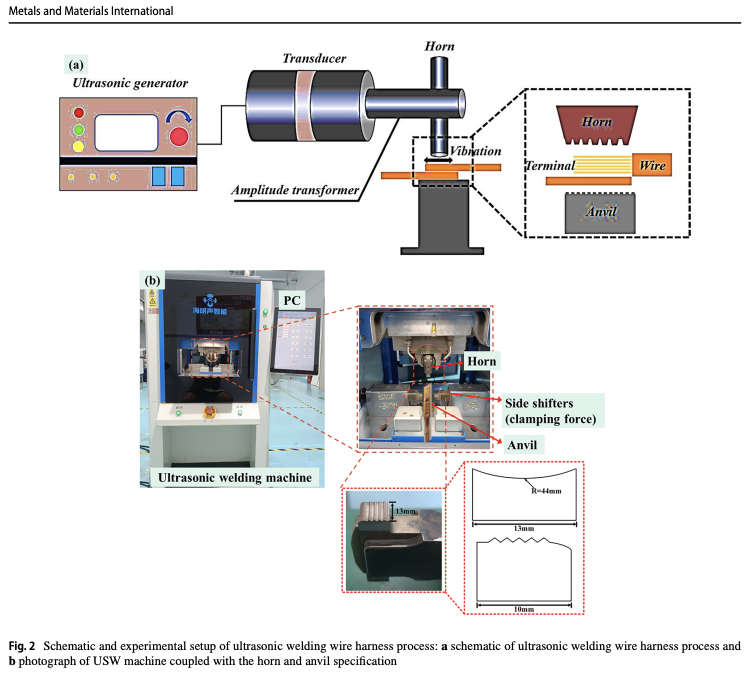

Ultrasonic wire welding is considered a method of choice for creating reliable interconnects in electronics industry including aerospace, batteries and electric vehicles. In this paper, ultrasonic welding tests between EVR252 copper wire and substrate are carried out. Novel pattern morphologies are machined on substrates to explore its influence on mechanical properties of welded joint. Patterns are divided into three different categories e.g., original surface, vertical and horizontal shapes. Cracks, microstructure strength and tensile properties of welded joint are studied and its joining mechanism is analysed. Compared with the reference substrate (S1), the welded joint performance of the longitudinal patterns (S2, S3, S4) has been improved, among which the longitudinal pattern (S4) has the most significant improvement (+ 15%). Likewise, the performance of transverse pattern (S5) welded joints is relatively poor (− 16%). The microstructural analysis using SEM has revealed predominant joint strength on Cu wire surface while maintaining rock-like and compact properties of S4 substrate. Upper side of wire-harness compactness is frequently observed due to vertical direction of patterns on substrate and also increases the strength of welded joint. Values of failure load, failure displacement and failure energy absorption were increased by 7.9%, 72% and 35% for S2, 6.1%, 75% and 42% for S3 and 15%, 87% and 113% for S4 compared to S1. Failure modes of welded joints are mainly characterized into: 1-poor ductility or rupture (no deformation) failure in vertical 3-line pattern joints 2-cylindrical deep holes failure in vertical 3-line zigzag pattern joints and 3-bulging effect failure in horizontal 3-line zigzag pattern joints. Point and line scans EDS measurement were performed to investigate weaker and stable trends of different locations in welded joints. In S4 substrate, 17.9% carbon content at the position of welded joint was investigated, leading to content of less oxides and fraction impurities. However, S1 weld zone contains 38.7% carbon content which can weaken welded joint and reduce durability. Graphical Abstract: (Figure presented.).

Keywords

Copper substrates, Failure and strength analysis, Machined patterns, SEM and EDS analysis, Ultrasonic welding wire harness, Carbon, Copper, Electronics industry, Substrates, Ultrasonic testing, Ultrasonic welding, Welds, Wire, Copper wires, Failure and strength analyse, Machined pattern, Strength analysis, Ultrasonic weldings, Welding wires, Wire harness, Failure (mechanical)

Reference

Abbas, Z., Teng, F., Zhao, L. et al. Influence of Patterns on Mechanical Properties of Ultrasonically Welded Joints in Copper Substrate and Wire. Met. Mater. Int. (2024). https://doi.org/10.1007/s12540-024-01646-4