HelmIQ: Revolutionizing Safety with Intelligence.

- Post by: Tobias Larsson

- 14th January 2024

- No Comment

Smart Helmet

Programme: Mechanical Engineering

Course: Project in MT2573 : Transformative PSS Innovation

Corporate partner: Volvo Construction Equipment

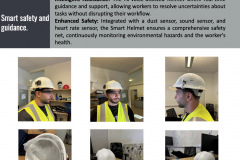

Challenge: Integrating advanced technologies like AI assistance, safety sensors, and a user-friendly HUD into Volvo CE’s smart helmet while maintaining a comfortable and durable design. Achieving a harmonious balance between innovation, productivity, and safety was crucial for success in the dynamic construction environment

Solution: Safety and productivity are the two main aspects of a construction site. Balancing these two priorities is paramount to ensure the efficiency of operations and, more importantly, the well-being of the workers and the project’s overall success. Therefore, integrating cutting-edge technologies like smart helmets can play a pivotal role in achieving this delicate equilibrium by enhancing safety measures while concurrently boosting productivity through innovative features and real-time assistance

Impact: The smart innovative helmet by Volvo CE has a profound impact on the construction industry. By integrating advanced technologies, it enhances safety through real-time monitoring and immediate hazard alerts, significantly reducing accidents. Simultaneously, the helmet streamlines work processes, minimizing downtime, and boosting overall productivity. With its ergonomic design and a Head-Up Display for quick information access, the helmet ensures user comfort while optimizing decision-making on construction sites. In essence, it revolutionizes workplace safety, efficiency, and productivity standards

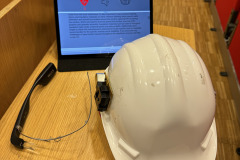

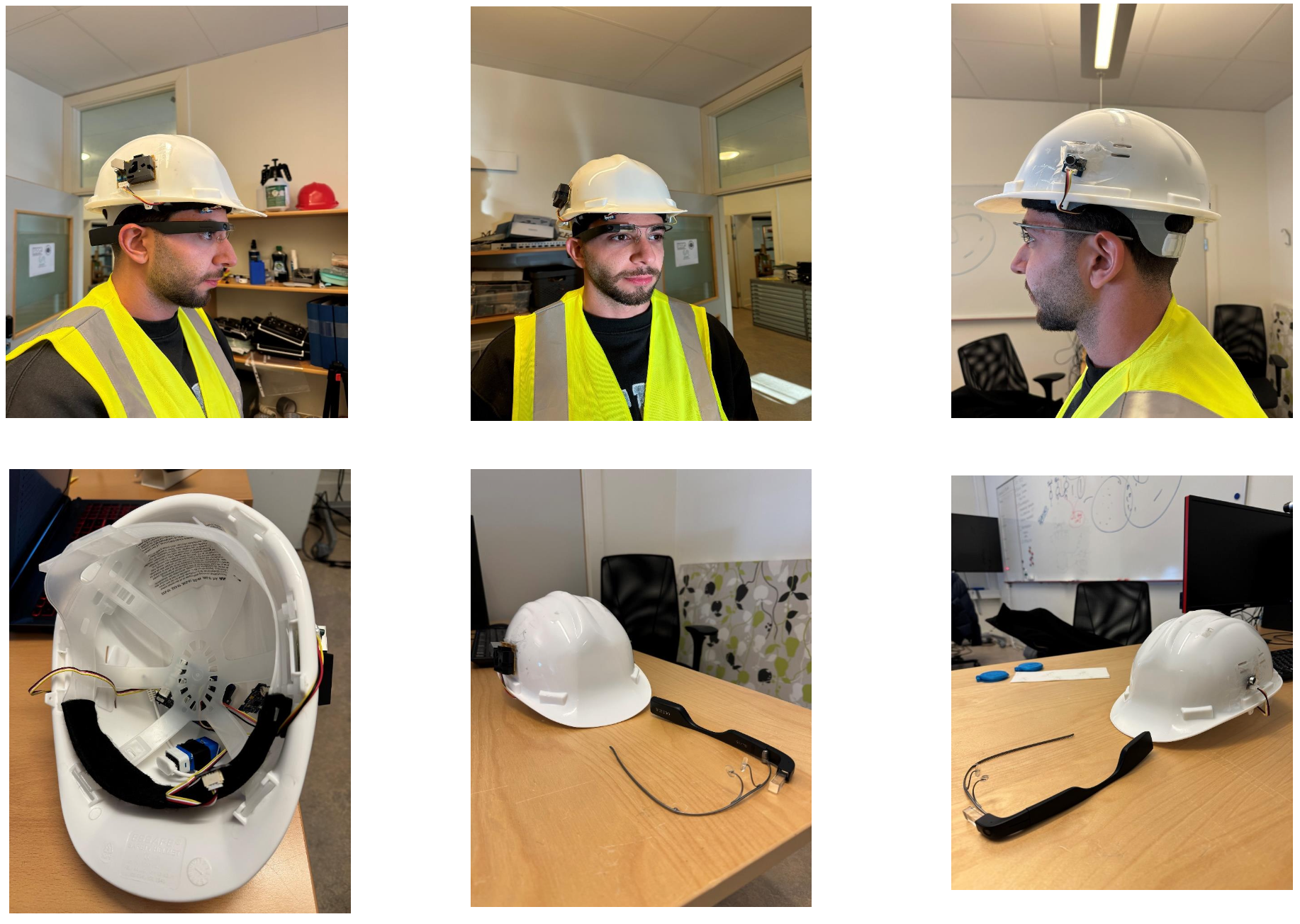

Prototypes:

During the 5 month of work, we made a total of 3 prototypes:

- The first prototype was a simple security helmet where we add a fan in order to curb the heat problem highlighted by constructions workers. We learnt that first it’s did not cool down but as well add some noise issue as the fan was noisy and close to the worker’s ears.

- For the second prototype, we still take a simple security helmet, and we added a plastic film to reflect the screen of a phone in order to have a HUD in front of our eyes. The main problem was the reading direction and rotation of the projected text due to the thickness of the plastic film.

- For the last prototype, we continue working on the HUD system, but we went further with it. We 3D print a “box” for the phone to have an area for it where it can be put in while not maintaining it with our hand in order to have free hands. We also change the plastic film to a thickness one. We learnt that the doubling and reverse problem from the previous prototype was way reduce. However, due to the weight of the 3D print piece in front of the helmet, the users tended to have his head tilted forward so we added some small counterweight at the back of the helmet.

Quotes from sponsor/partner:

“You are free to do everything you want, you can go crazy with the word “smart”.”

/Martin FRANK, Project contact at Volvo

“Wrote down everything you managed to find during those 5 months of work, it will always be useful for us at the end.”

/Martin Frank, Project Contact at Volvo

Project team:

- Simon Bååth: MSC in Mechanical Engineering, class of 2019

- Kevin Ha: MSC in Mechanical Engineering, class of 2019

- Benjamin Domenge: ERASMUS student studying General engineering program at ECAM Lyon, class of 2020

- Omar Abasi: MSC in Mechanical Engineering, class of 2019

- Aghiad Mijel: MSC in Mechanical Engineering, class of 2019

More info

Image Archive