Digital Twin research on IVA 100 list for 2022

Read More

Digital Twin research on IVA 100 list for 2022

- 11th May 2022

- No Comment

8th of October was the Academic Ceremony at BTH with promotion of PhD’s and installation of professors among other things on the agenda. From Product Development Research Lab and the […]

Read More

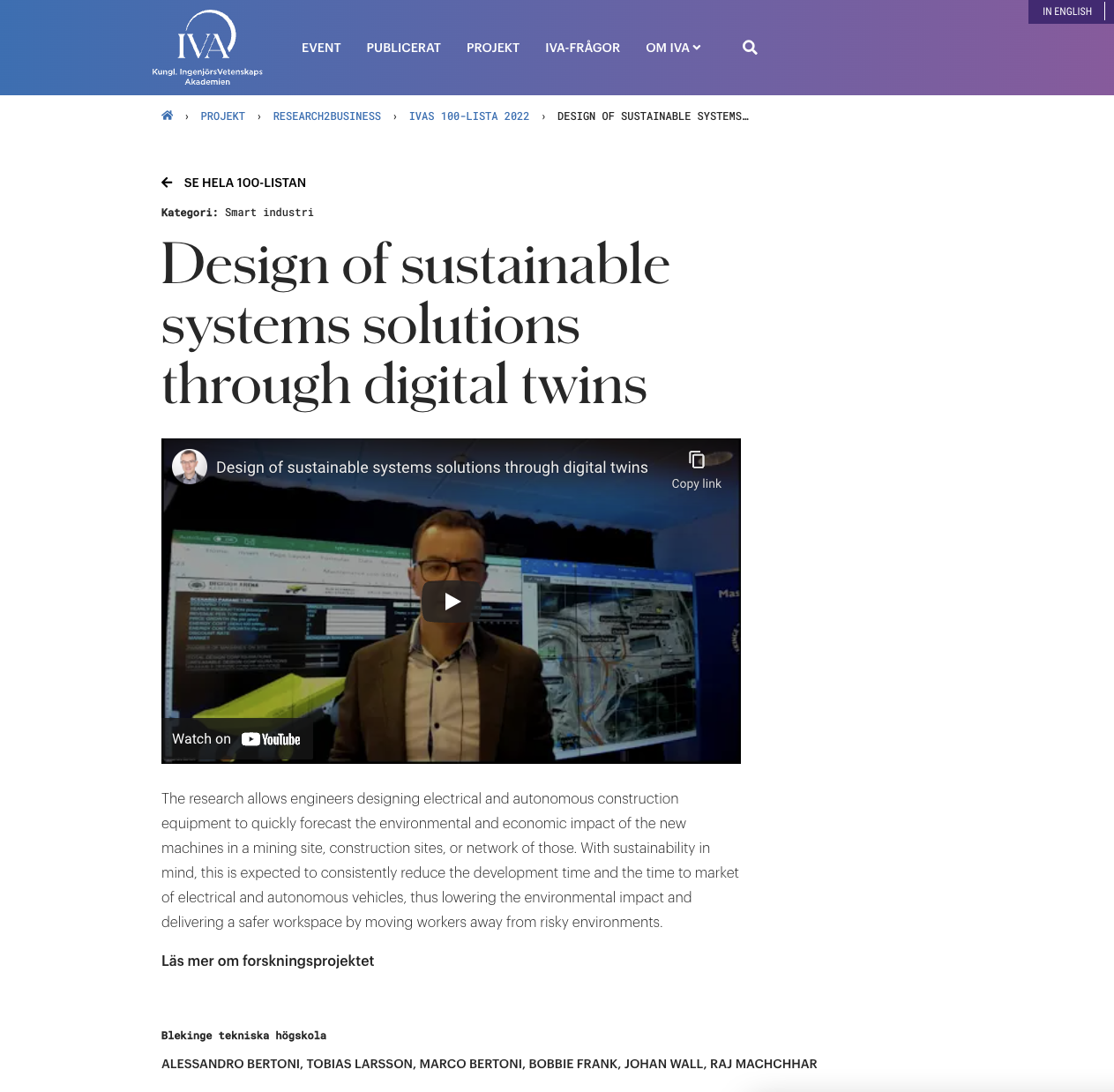

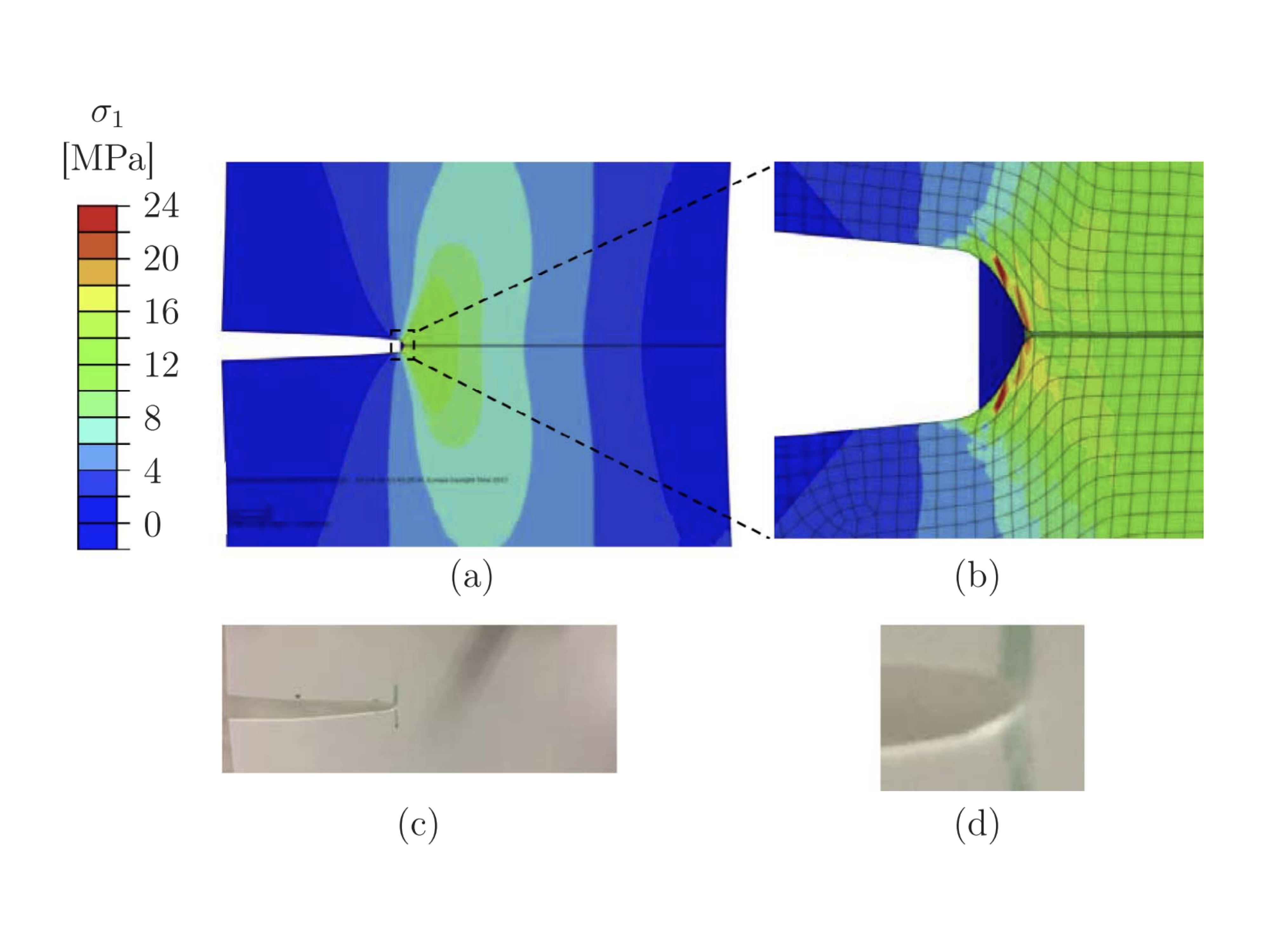

Abstract Large displacement peel was studied for cases where a compliant substrate leads to a large value of the root rotation. An existing simplified beam model to calculate the peel […]

Read More

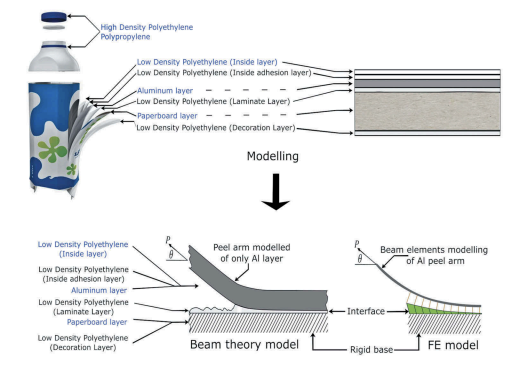

Abstract This research has investigated the essential work of fracture (EWF) from trouser tear test of polyethylene terephthalate (PET), low-density polyethylene (LDPE) films and their corresponding laminate using a convenient […]

Read More

Today, Shafiqul had a morning of presentation and discussion as he defended his PhD thesis “Fracture and Delamination in Packaging Materials: A Study of Experimental Methods and Simulation Techniques” in front […]

Read More

Eskil Andreasson successfully defended his PhD thesis “Mechanics and Failure in Thin Material Layers – Towards Realistic Package Opening Simulation” in front of a full house and grading committee, and […]

Read More

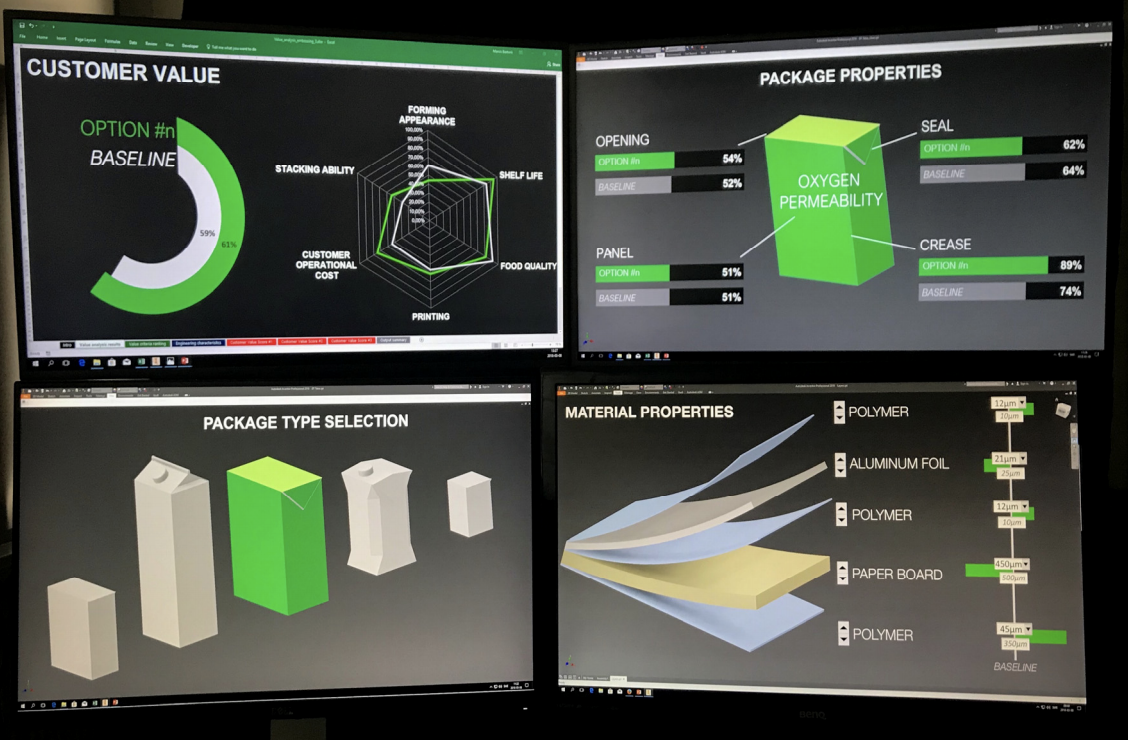

ABSTRACT Consumer perception of food packaging solutions is driven by early design decisions on paperboard configuration and manufacturing technologies. Simulation Driven Design is common to frontload design activities, but is […]

Read More

En delegation bestående av forskare från bland annat BTH, Lunds universitet, Swerea IVF, Tetra Pak och Volvo Cars har diskuterat hållbar materialformning och dess tillämpningar inom bil- och förpackningsindustrin vid ett veckolångt besök i Kina. Symposiet arrangerades av BTH, Shanghai Polytechnic University och Kunming University of Science and Technology.

Read More

ABSTRACT The fracture mechanics properties of injection-moulded low-density polyethylene (LDPE) sheets were investigated both experimentally and numerically. The total work of fracture was determined experimentally, by means of fracture mechanics […]

Read More

In the Extreme PSS Innovation course, students from BTH’s masters programmes in Mechanical Engineering, Industrial Management and Engineering, and Sustainable Product-Service System Innovation (MSPI) are given challenges from real industrial companies to solve. The course is a central part of BTH’s mantra “In Real Life”.

Read More