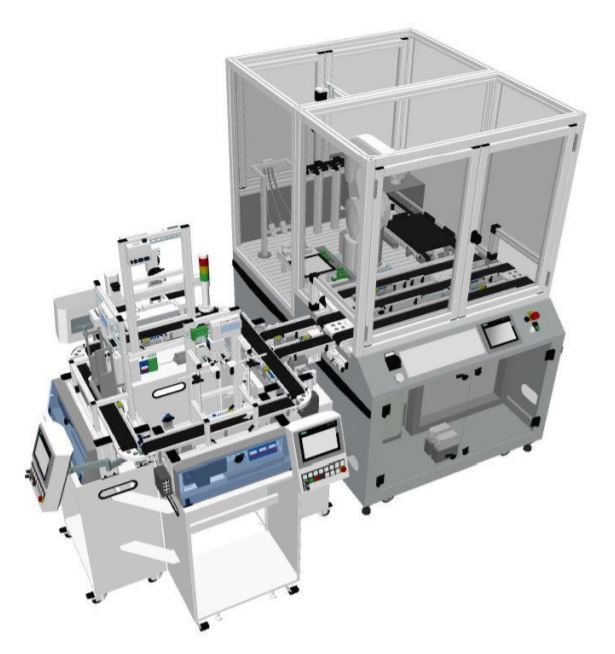

The partners of I-STAMP project met in Mondragon Spain between 6th and 7th February to discuss project progress and exchange learnings. I-STAMp project aims to develop cost-effective and affordable actuators […]

Read More

I-STAMP project progress meeting in Spain

- 12th February 2023

- No Comment