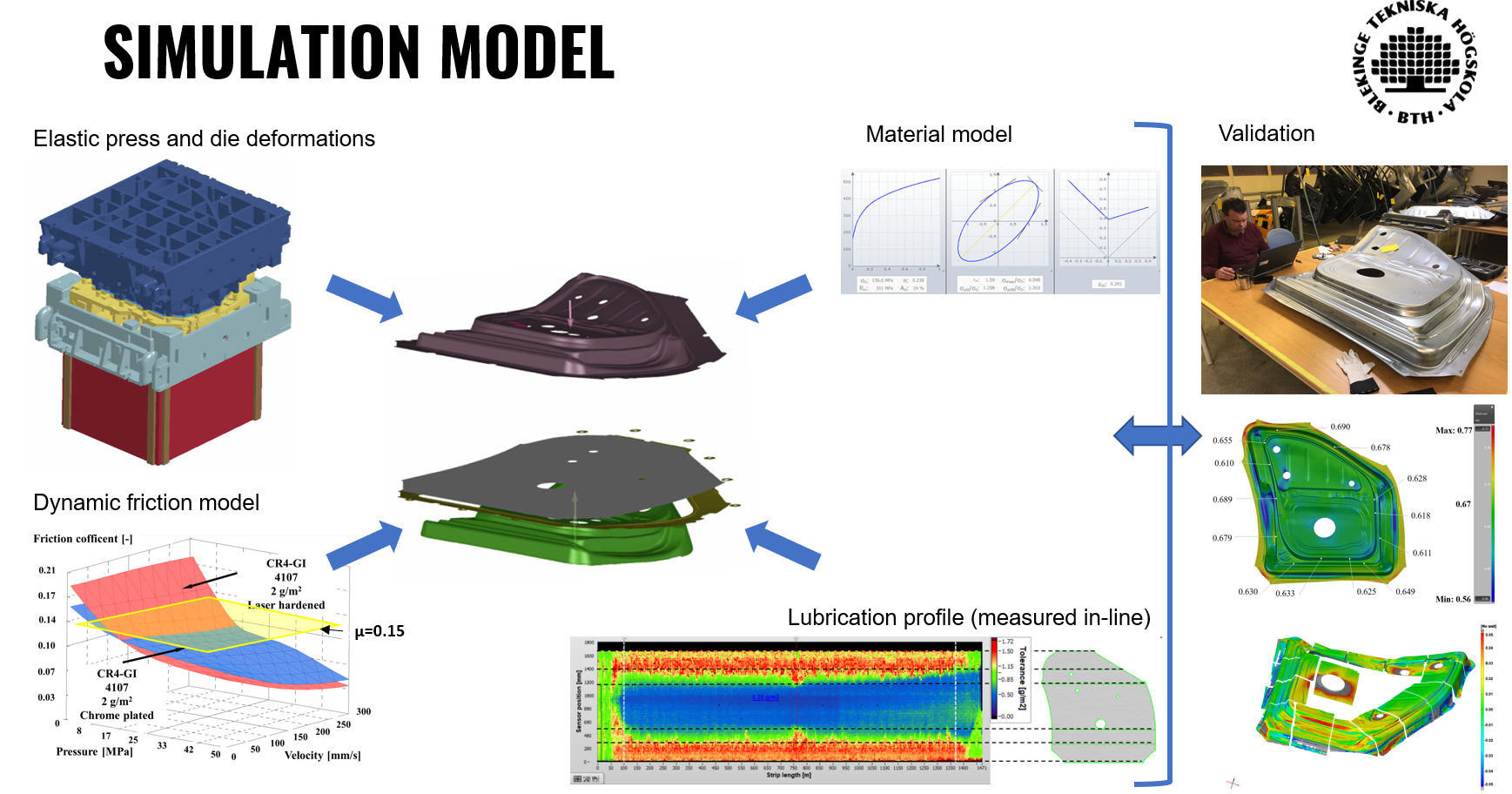

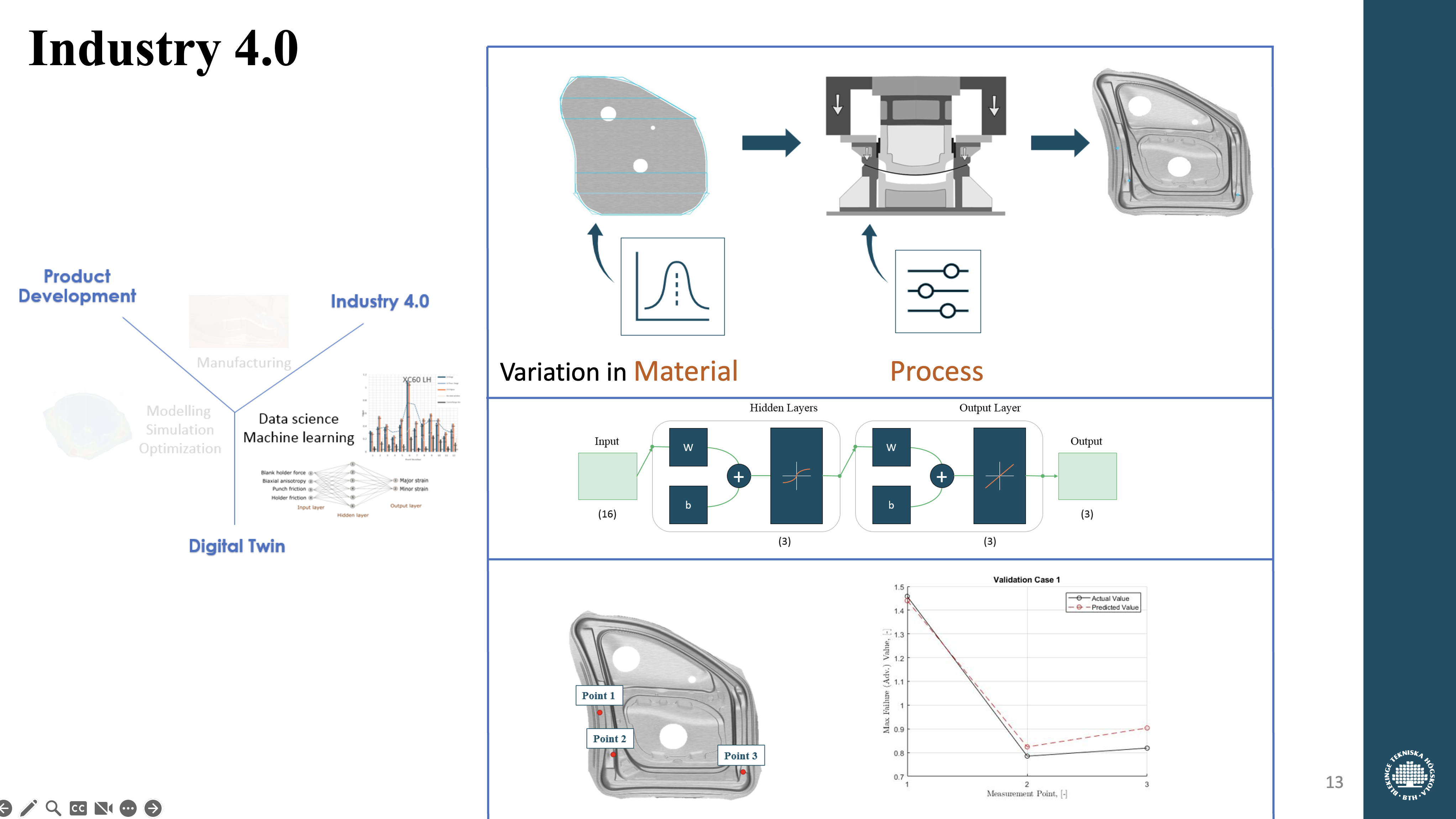

The PREDICT project have been running between 2020-2024, and was recently closed. Project leader Shafiqul Islam shares the project summary in this video. PREDICT has generated results and tools that […]

Read More

PREDICT project finalized with good results!

- 5th August 2024

- No Comment