V-Com presented at Stanford University

- Post by: Christian Johansson

- 25th June 2019

- No Comment

V-Com, a precautionary system that communicates safety-critical information between truck drivers and vulnerable road users was presented by six final year MSc students from Blekinge Institute of Technology and Stanford University at this year’s Stanford EXPE – design experience. In their capstone project, ME310, which runs from October to June, they move in a Design Thinking process through phases of needfinding, ideation, prototyping and more to arrive at a final detail designed product to display at the final exhibition, the EXPE.

The BTH team of Dastan Gomli and Erik Lindström, having worked with their American colleagues (Charvi Aggarwal, Catie Cuan, Gaurav Gude, and Bhargav Reddy) using distance-spanning technology through the better part of the academic year, travelled to Stanford a few weeks before the final event to complete the final system prototype.

This year’s project was the first time that Volvo Group Connected Solutions, with its Innovation Lab that has recently established an office just a stone's throw from Stanford in Mountain View, was project sponsor having taken over the baton from sister company Volvo CE. Jenny Elfsberg, who is heading up Volvo Group’s Silicon Valley office, and also has been involved with ME310 during a decade explains why this sponsorship is so valuable to the company;

“The ME310 course is a great way for our company to engage with academia and both support the students and generate unique value for the company. During a full school year with a team of students both in Sweden and USA we get to take part in a design thinking journey, from day one, when we provide the challenge, and all the way through. We get to witness the struggle with a distributed team finding ways to collaborate effectively, we get to see their needfinding activities and their insights, which by itself adds tremendous value to us, because we rarely have time to perform proper, in-depth needfinding, and when we do it many of us have difficulty to see beyond the traditional Volvo product range, which is crucial in order to identify truly valuable innovative solutions. We also get to see several prototyping iterations – including testing of the prototypes, from which we learn a lot. The final presentation, at the ME310 EXPE, only give a brief taste of the full year experience. The way we get to engage with the faculties – both at Stanford and BTH, the master students and the design journey is truly unique, and time and money well spent.”, says Jenny

The prompt – “Enhancing partnership between humans and vehicles in the connected society”

Automation, electrification and connectivity is changing our society. Volvo Group with Trucks, Buses and Construction Equipment are working with different and increased levels of these capabilities. With these changes, they want to understand how professional drivers and operators are affected since full automation is still somewhat distant in the future and the transition will be gradual. They also want to understand how to improve the quality of the professional drivers and the operators lives by leveraging the positives of the new technology.

At the same time as vehicles and machinery is advancing, the entire society is becoming more connected, with the advent of the Smart City around the corner. The drivers and operators will become collaborators with inhabitants and infrastructure of the Smart City. Vehicles will need to operate safely and efficiently in connected urban environment. Volvo wants to explore and develop the relationships between citizens, drivers/operators and the smart solutions in this landscape – via the assistance of technology.

“I think this year’s challenge is a really interesting one from an innovation point of view because we are working at the intersection of several interesting developments, with future autonomous and electrified heavy vehicles are brought into the mix of the smart city where we will still have many unprotected road users inhabiting the streets. This gives an opportunity for novel solutions to serve needs of these stakeholders that I have confidence in the students to uncover.” , says Christian Johansson Askling, responsible teacher from BTH.

About V-Com

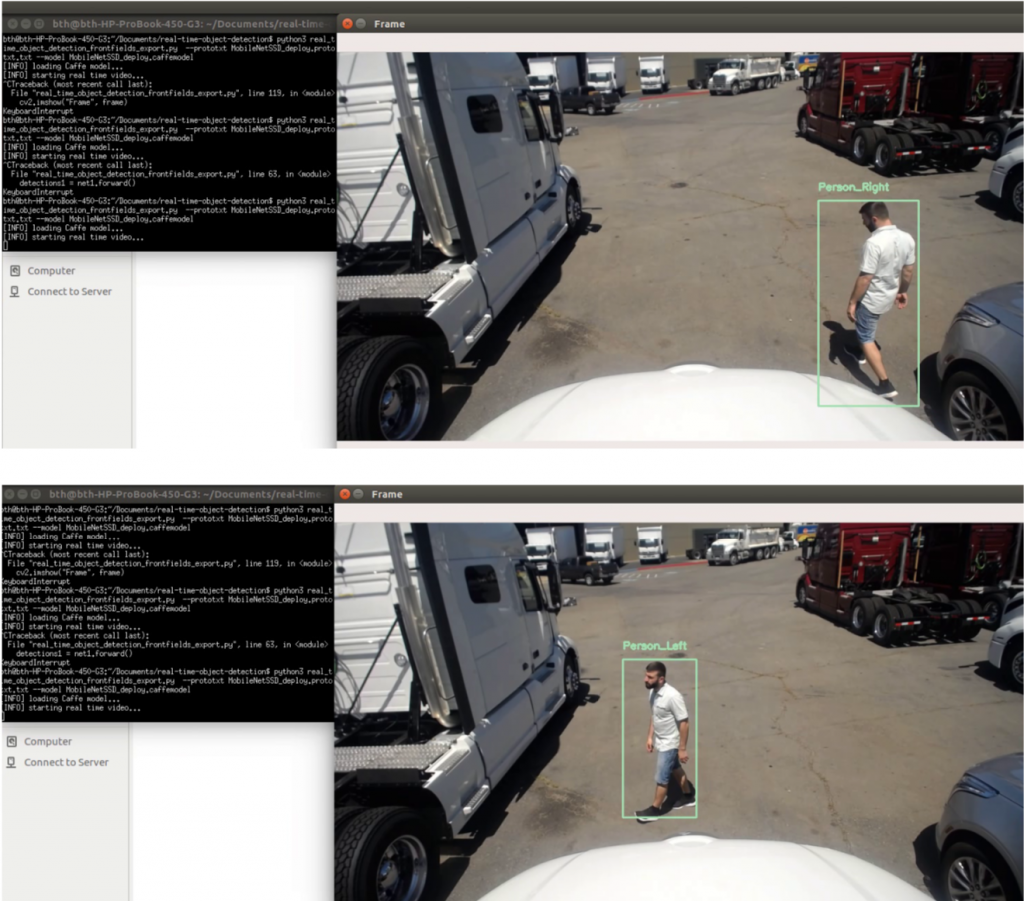

V-Com is a system of sensing, computation and communication components that aims to support vulnerable road users as they are in the near proximity of large vehicles, such as buses and trucks. For this prototype, the students have mounted their solution as an add-on on a truck.

The sensing technology consists of two parts; first a vision system that uses machine learning algorithms to detect people in the close proximity. The second part is a series of ultrasonic sensors that are mounted on the side of the truck and that sense where on the side of the truck an obstacle is located.

With this information the computing algorithms determine what is the appropriate response that the communication parts of the system should emit.

The communication part of the solution consists of a series of high-intensity LED-matrices and audio output speakers that are mounted around the truck. As a pedestrian or cyclist come within a close proximity of the truck, the outputs will alert them about that they are observed to be close and also what the intentions of the vehicle is. At the same time the truck driver is also alerted about the presence of vulnerable road users close by. The system is also able to detect where the driver has their attention directed and convey this information to the people outside.

In the future, as we see a transition towards higher levels of autonomy in traffic, and also in trucks and buses, this type of system can be a valuable addition to the collaborative interface between autonomous vehicle and vulnerable road users, specifically in urban areas.

Presenting at EXPE

On June 6 the team consisting of two Mechanical Engineering students from BTH and four Mechanical Engineering students from Stanford University presented their final product, the V-Com, at EXPE at Stanford University’s campus in California. The team delivered an informative presentation about the challenge, trends in society, the needs of their users, and ultimately the solution and its technology in Hewlett’s main auditorium.

In the afternoon, the team had brought in a delivery truck on campus upon which they had assembled and mounted the V-Com system for live display. Visitors got to experience the system in live operation and had the opportunity to talk with the students about the presented prototypes as well as the journey to reach this results. Further, the students had facilitated a tour of the past 9 months of work – through various design activities and prototypes – in the back of the truck, where many interesting discussions and views was raised by visitors to the team’s booth.

Tommy Hansson, responsible for Innovation Lab at Volvo Group Connected Solutions, says about the results:

“What is exciting with this team’s work is the focus on the intermediate period between fully autonomous and where we are today – how we can improve our safety solutions through this concept that the students developed. Generally, you either focus automation full-scale in 5-10 years or you look at today's solutions, but this I think addressed the gap in between. It is very interesting to be able to give feedback back to the pedestrian and reinforce the communication between the vehicle, the driver, and the pedestrian. ”

Chris Konnick, HR business partner for staff and support, continues about working with students:

“I was really impressed with how they came up with a very practical everyday solution that is very innovative, but also somewhat out of the box. They tried to make something that not only leads Volvo's products forward but that also an innovation for everyone in the community as well.”

The next step for the prototype is now for Volvo to bring the prototype into their Silicon Valley innovation office, the Hub335, for continued exploration and integration with other developments. Further, the results will be communicated in several other business units where the solution, ideas, and also needs that were uncovered will be food for further developments into this field of seeking further safety gains for vulnerable road users.

Tommy continues;

“We will now spread this within the Volvo Group. Based on that we will see what we can take further in projects that are going on and new initiatives. We will actively facilitate the knowledge transfer.”

Further on the value of working with students in these kinds of projects, Tommy continues:

“What I think is beneficial with students is that they are new to these areas; with beginner’s mind and new perspectives. Also, the methodology that is used, starting from a Needfinding perspective, means that you go in with open eyes and not really have a solution in mind. You are not clouded by your surroundings. It is common when you have worked in a large company for a while – and have been in that domain, in that team – to ave a fixed direction – which is something the students don't have.”

Chris continues about working with students:

“I think the biggest benefit was using students in any class and especially in this one is that they have the benefit of not knowing what they can’t do. As an employee, you focus on what you can’t do and what’s the limit, whereas for the students the sky's the limit for them.”

Further, for Volvo, Chris says that the benefits of working with potential future employees in this program is:

“This is a great way for Volvo to attract talent because the way you attract talent is getting people excited to work for you, and by tapping into these ideas and interacting with these students you’re learning first-hand what future candidates and future generations want to work with and what motivates them. If you can implement that when they're ready to join the workforce – they feel invested already before they start working for you and your ideas. They know they were creating the ideas of the future; ‘I want to be a part of that future’.“

Now, as summer is approaching and the semester draws to a close, Erik and Dastan will finalize their master thesis, and continue towards moving from university studies to the next step in their careers into employment in industry, hopefully practicing design thinking principles for many years to come.

Previous projects and info

The ME310 course at Stanford University is a three-quarter global design course starting in October and finishing at the EXPE event in June. The course features ten corporate-sponsored projects that all have global partner universities from around the world. For the last four years, mechanical engineering at BTH have been the only Swedish participants. Sponsors include major global brands, such as Volvo Construction Equipment, the Volkswagen Group, Renault, and SAP to name a few.

The curriculum for the course is Design Thinking, depicting an entrepreneurial approach to design with much emphasis of prototyping as an approach to open-ended ill-defined problems where the students make extensive needfinding to define the problems. This is the same as the core curriculum for the MSPI program at BTH, which means that our students are somewhat familiar with the approach to design that is practiced.

“- ME310 Global Design Innovation and the Design Thinking approach is proving itself to be a valuable experience for both students and partners. For BTH students to be able to collaborate “in real life” with one of our research partners, and also with prestigious Stanford University, is simply a great experience. Challenging, but also rewarding”, says Professor Tobias Larsson of BTH Mechanical Engineering.

For more information about the ME310-project, including previous years’ projects, and PDRL’s Stanford University collaboration, see the pages listed below;

- All ME310 related

- All ME310 2018/19 related

- ME310 2017-2018: The pains of today and concerns of tomorrow (Volvo CE)

- ME310 2016-2017: From elephants to ants – from earth to Mars (Volvo CE)

- ME310 2015-2016: Human-Autonomous Machine Interaction (Volvo CE)

- ME310 2014-2015: Urban Mining (Volvo CE)

- ME310 2013-2014: Urban Mining (Volvo CE)

- ME310 2012-2013: Idéum (Volvo CE, Michano AB)