Fracture toughness analysis of aluminum (Al) foil and its adhesion with low-density polyethylene (lpde) in the packing industry

- Post by: Tobias Larsson

- 22nd July 2021

- No Comment

Abstract

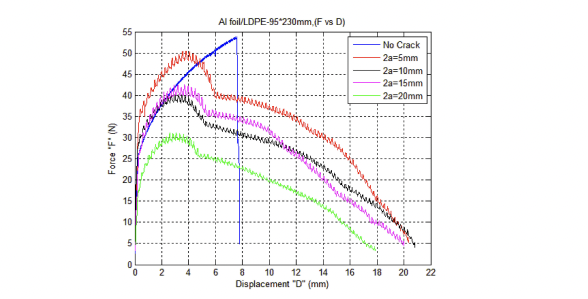

Liquid food packages consist of various polymers films, which are bonded together with Aluminum foil (Al-foil) using adhesion or by direct heat. The main aim of this research was to define important material properties such as fracture toughness and some FE-simulation material model parameters such as damage initiation, damage evolution, and the adhesion between Al-foil and low-density polyethylene (LDPE) film. This investigation is based on both physical experiments and FE simulations in ABAQUS with and without initial cracks of different lengths for comparison purposes. The final FE model in ABAQUS was used to compare the numerical input parameters in an extensive study with the ambition to investigate the materials’ parameters in cases with or without adhesion between laminates. Finally, the relation between the theoretical and experimental results for Al-foil using linear elastic fracture mechanics and modified strip yield model were shown, and the fracture toughness was calculated for two different thicknesses of Al-foil.d that it is up to the individual designer whether they exhibit paternalism in their design decisions or not.

Keywords

PAluminum foil, FE model, Fracture toughness, Laminate, LDPE film

Citation

Sharif, U.; Sun, B.; Islam, M.S.; Majeed, K.; Ibrahim, D.S.; Adewale, O.O.; Akhtar, N.; Zaki, Z.I.; El-Bahy, Z.M. Fracture Toughness Analysis of Aluminum (Al) Foil and Its Adhesion with Low-Density Polyethylene (LPDE) in the Packing Industry. Coatings 2021, 11, 1079. https://doi.org/10.3390/coatings11091079.