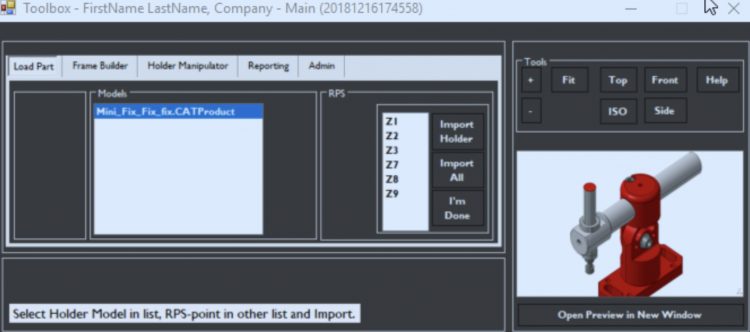

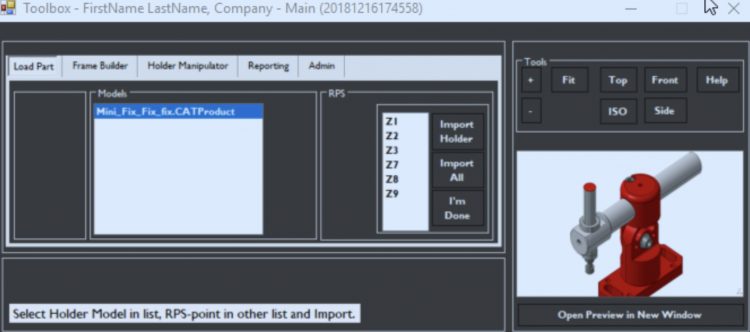

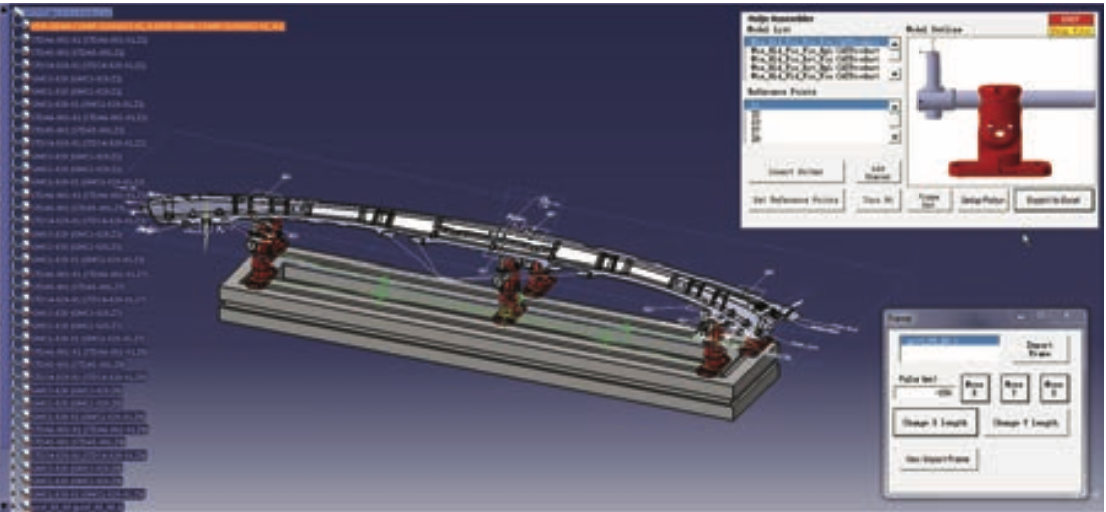

Abstract In the production of automotive body components, fixtures are an important part of the ongoing work on geometrical assurance. The fixture is uniquely defined for each component, and the […]

Read More

Abstract In the production of automotive body components, fixtures are an important part of the ongoing work on geometrical assurance. The fixture is uniquely defined for each component, and the […]

Read More

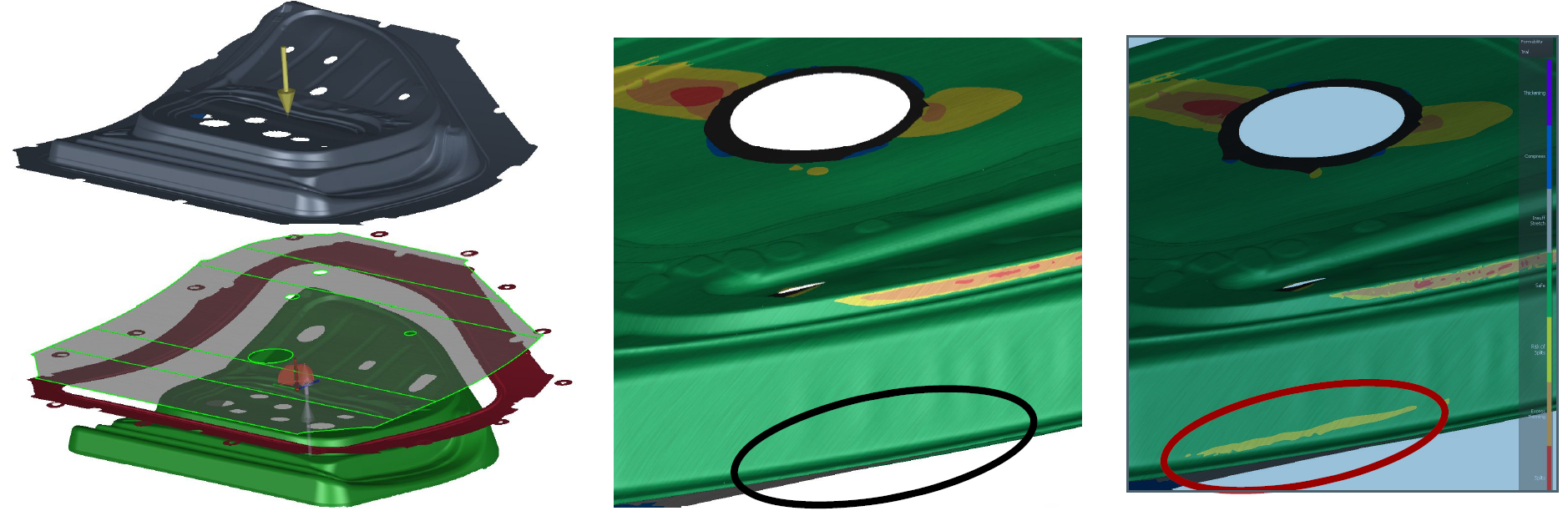

ABSTRACT With growing demands on quality of produced parts, concepts like zero-defect manufacturing are gaining increasing importance. As one of the means to achieve this, industries strive to attain the […]

Read More

ABSTRACT In production of automotive components, control-measuring is an important activity to assure that geometries meet expected tolerances. This is done via randomly taking parts out of production for control-measuring […]

Read More