Reverse Engineered Design Automation: Applying Knowledge Based Engineering Techniques to a Case of Automotive Fixtures Design Configuration

- Post by: Christian Johansson

- 22nd August 2019

- No Comment

Abstract

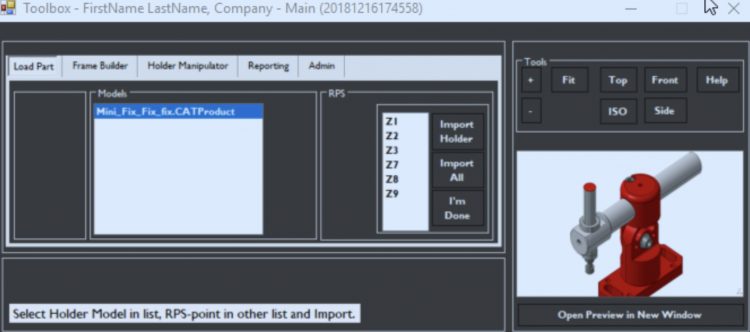

In the production of automotive body components, fixtures are an important part of the ongoing work on geometrical assurance. The fixture is uniquely defined for each component, and the design and configuration of these are time-consuming and takes a lot of effort. The objective with this paper is to explore the use of a design automation approach and application to semi-automate the configuration process of the fixture product. The paper presents an approach to automate the configuration of the fixtures in a flexible way, by reverse engineering the configuration of the fixture product from a generic blueprint that represents the expected outcome of the process, using a knowledge-based engineering approach applied to a computer aided design (CAD) environment. A reverse-engineered design automation toolbox for a CAD-software is developed. The toolbox is developed to lead a user through the configuration process, in the way that the experts want it done, end-to-end, making use of some unconventional solutions from a design automation perspective.

Keywords

Knowledge management; Case study; Computer Aided Design (CAD); Design Automation; Customization;

Citation

Johansson, C. (2019). Reverse Engineered Design Automation: Applying Knowledge Based Engineering Techniques to a Case of Automotive Fixtures Design Configuration. Proceedings of the Design Society: International Conference on Engineering Design,1(1), 1583-1592. doi:10.1017/dsi.2019.164

Download

http://urn.kb.se/resolve?urn=urn:nbn:se:bth–18518

https://doi.org/10.1017/dsi.2019.164