The BTH Sugar Team visits Brazil to Fuel their Construction Innovation project

- Post by: Christian Johansson

- 26th March 2025

- No Comment

The BTH Sugar team recently completed a visit to Brazil as part of their global design innovation project. The team, currently focused on developing a system solution utilizing AI and machine learning to support productivity in construction, spent a week in São Paulo and Curitiba, engaging with academic and industry partners.

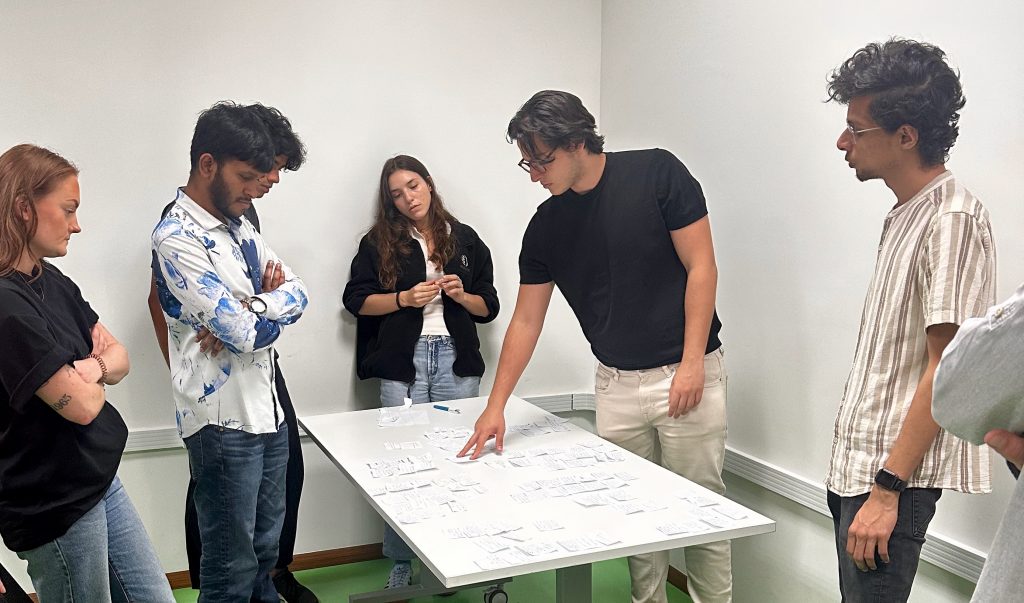

The trip commenced in São Paulo, where the team arrived at the University of São Paulo (USP) campus. The initial two days were dedicated to debriefing what they had learned from their recent Dark Horse prototype development. This session allowed the students to analyze their findings and identify areas for future focus.

Following their time in São Paulo, the Sugar team traveled to Curitiba, the location of the Volvo Group’s campus in Brazil. During their visit, the students delivered presentations to liaisons and other staff members at Volvo CE, outlining their project progress and initial concepts. These presentations led to discussions about potential future developments.

“It was valuable to have personal talks with the people at Volvo CE about their current systems in this field and to know more about what they like and would like to see improvements on,” says Maja Svensson, student from BTH.

A key aspect of the Curitiba visit was the opportunity for the team to engage with professionals in the field. They conducted interviews and had discussions with service professionals from Linck, Volvo’s local dealer organization. These interactions provided valuable insights into the practical aspects of working with Volvo’s construction machinery. Additionally, the team received a presentation on the various connected solutions currently used in Volvo construction equipment.

“The visit to the dealer gave good insight into how their expertise is utilized to provide swift and timely support to customers in dispersed locations,” says Madhav Kothareddy, student at BTH. “Also, many practical challenges with things like connectivity became apparent, showing what a robust solution must factor in,” Madhav concludes.

The visit to Volvo CE included a construction machine driving experience. This allowed the students to gain practical familiarity with operating both a wheel loader and a road grader.

“Seeing demonstrations of systems such as the site simulation and then having the opportunity to drive the machines for real gives many ideas on how to bridge the theoretical modeling and the practical experience for our future prototype,” says Mahfooz Ali Kahn, student from BTH. “It was also awesome to get first-hand experience driving some of the construction machines to understand the operator’s workload in their ‘office’,” Maja continues.

The day concluded with a dinner at a Mexican restaurant with the Volvo liaisons, accompanied by a Mariachi band.

“It was great to once again meet our friends in Curitiba and São Paulo for a well-organized visit with several valuable interactions and experiences for the students,” says Christian Johansson Askling, project leader from BTH. “The trip was incredibly beneficial for the team as a whole, and the VCE Brazil team did an amazing job providing the students access to front-line personnel at multiple levels of the organization,” says Ryan Ruvald, coach from BTH. “Many thanks to Marcio, Massami and their team for your support,” Christian concludes.

Upon returning to São Paulo, the team began processing the information gathered during their meeting with Volvo. This phase marked the start of discussions and ideation for their next prototype iteration, the “Funky System Prototype.” The team is now transitioning back to a distributed work mode, aiming to continue exploring the application of AI and machine learning to improve on-site productivity in construction.

In addition to their project work, the students had the opportunity to explore São Paulo, visit Paulista Avenue, and experience the local cuisine.

SUGAR Project-related information

About the SUGAR project: https://www.productdevelopment.se/education/stanford-me310-global-design-innovation/.

More information about this year’s project can be found at: https://www.productdevelopment.se/?tag=sugar-24-25.