Digital Twin

- Post by: Tobias Larsson

- 19th January 2020

- No Comment

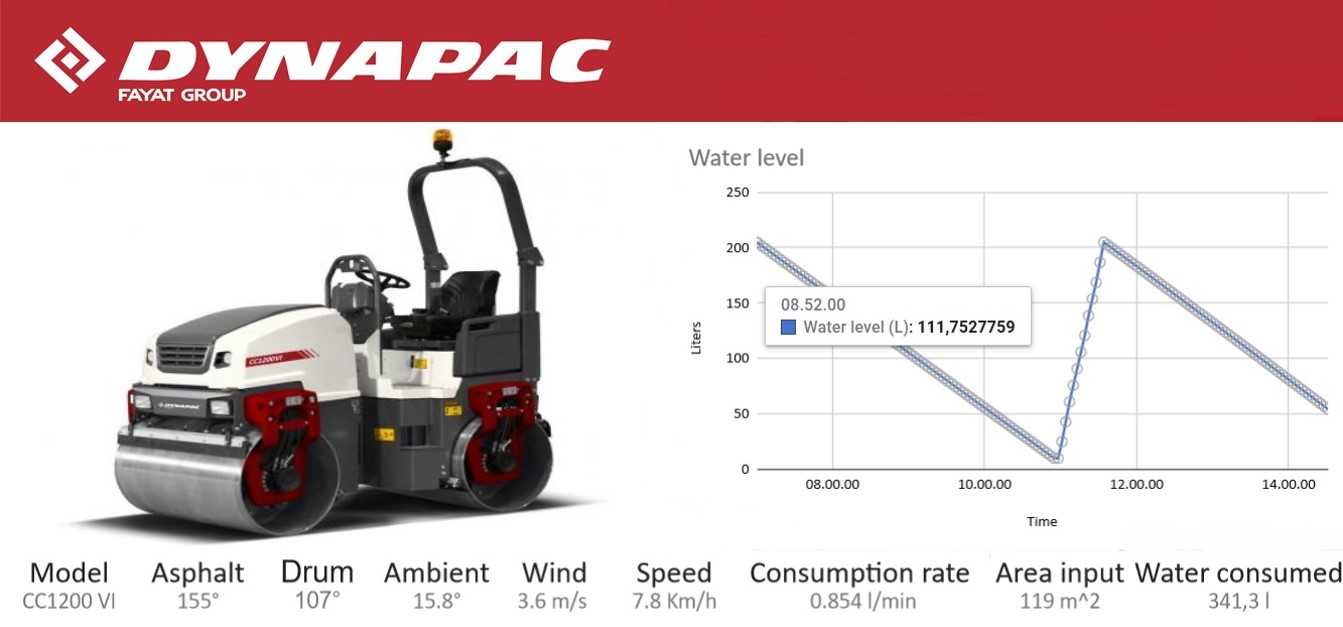

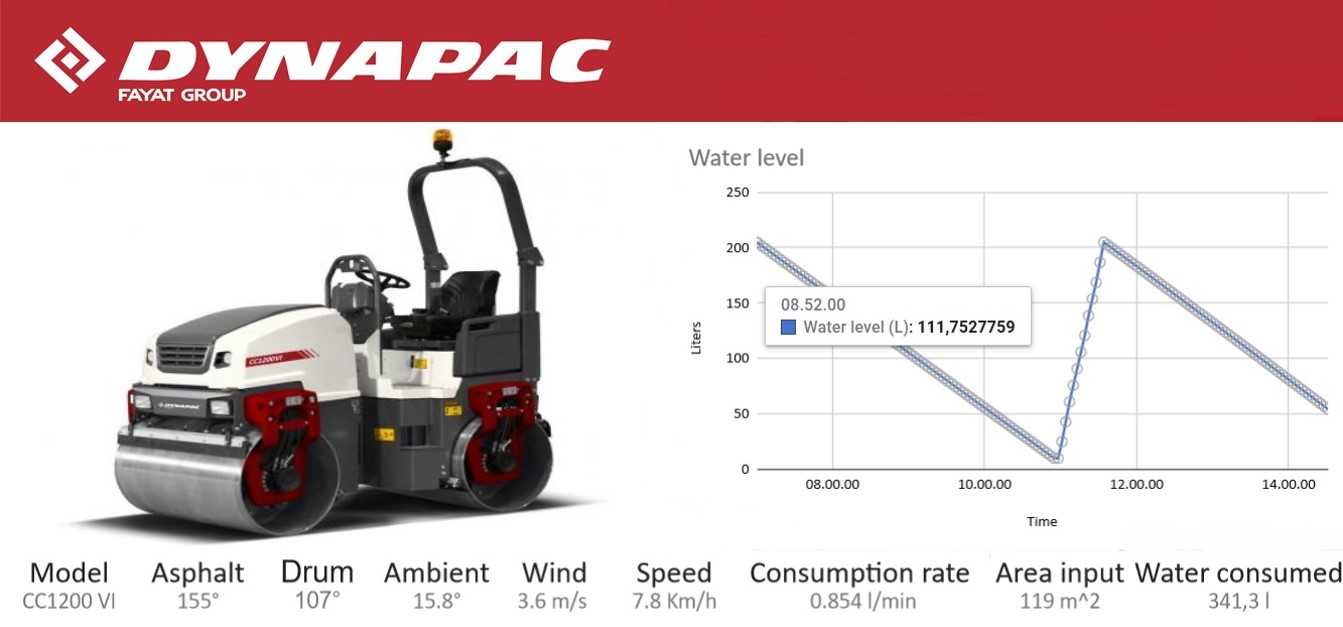

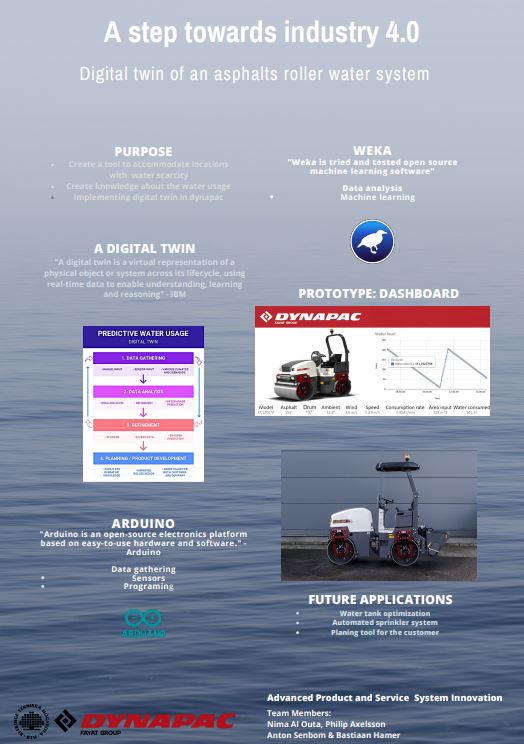

Predicting water usage on asphalt rollers

Programme: Master in Mechanical Engineering – Innovative and sustainable product development

Course: MT2556, Extreme Product-Service Innovation

Corporate partner: Dynapac

Challenge: By not knowing how much water is needed for a certain compaction job, construction companies have to estimate how much water is used for the whole job as well as on a day to day basis.

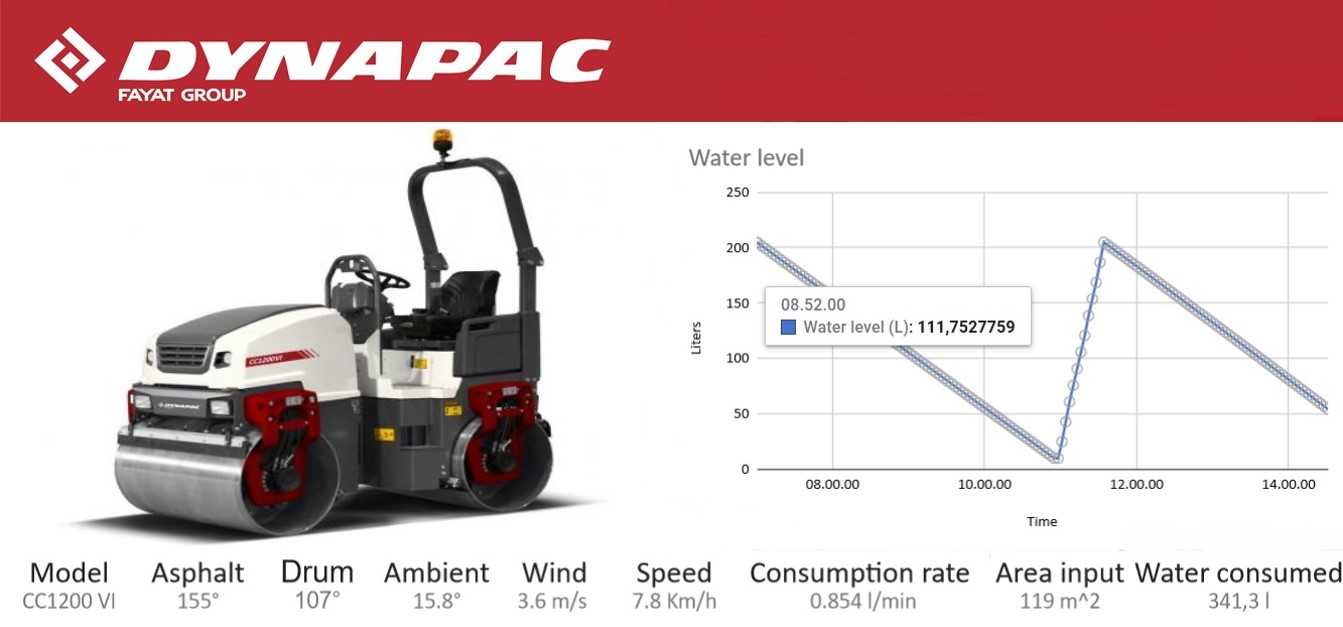

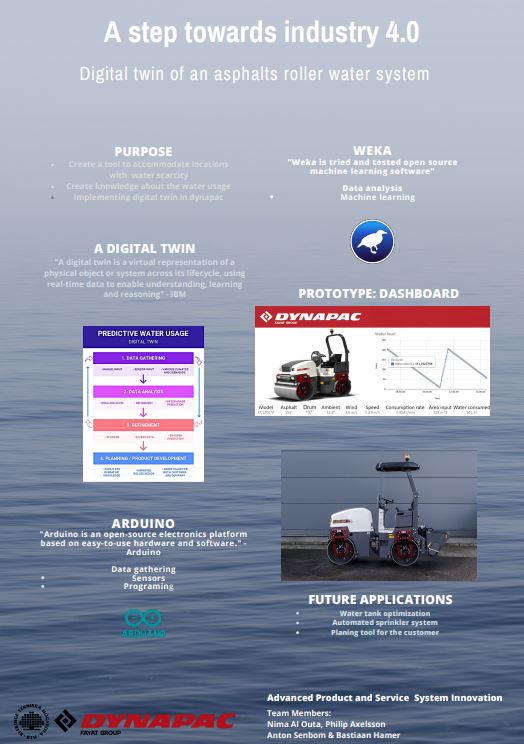

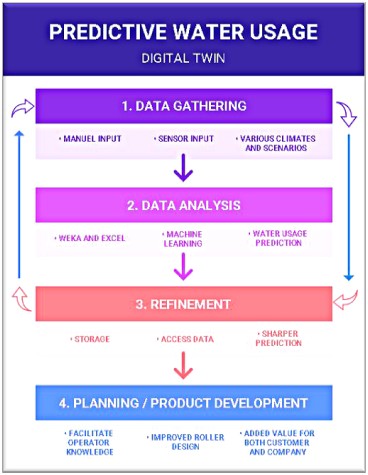

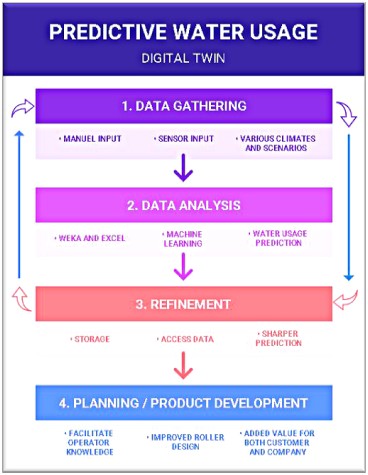

Solution: By implementing a digital twin which is able to predict water usage, the guess work is eliminated and there by time and money is being saved.

Impact: When it comes to Dynapac, they benefit from a digital twin of the watering system because they will receive data on how much water is being used and with the gathered information, they will be able to optimize the water tank for future rollers.

Prototypes:

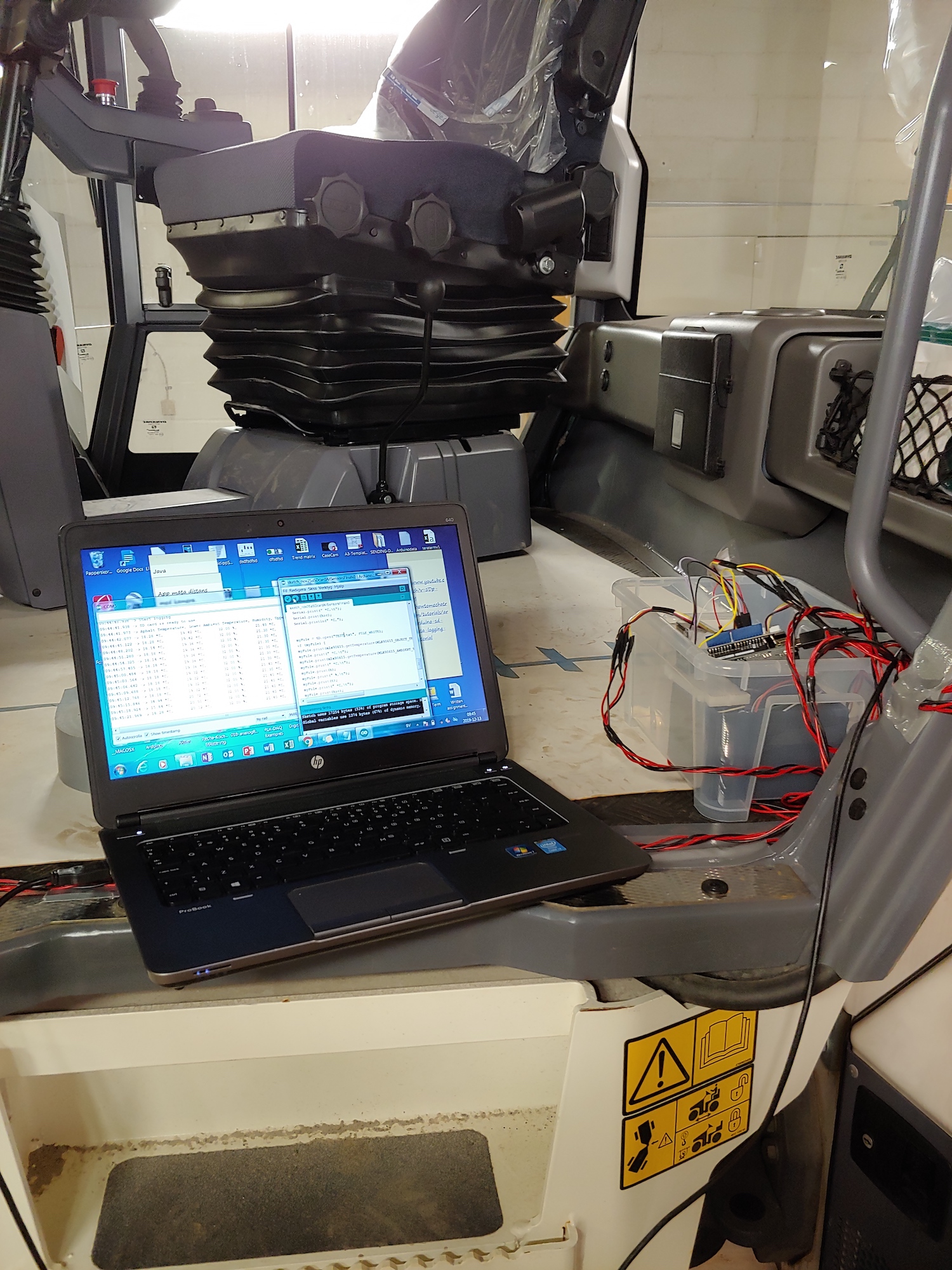

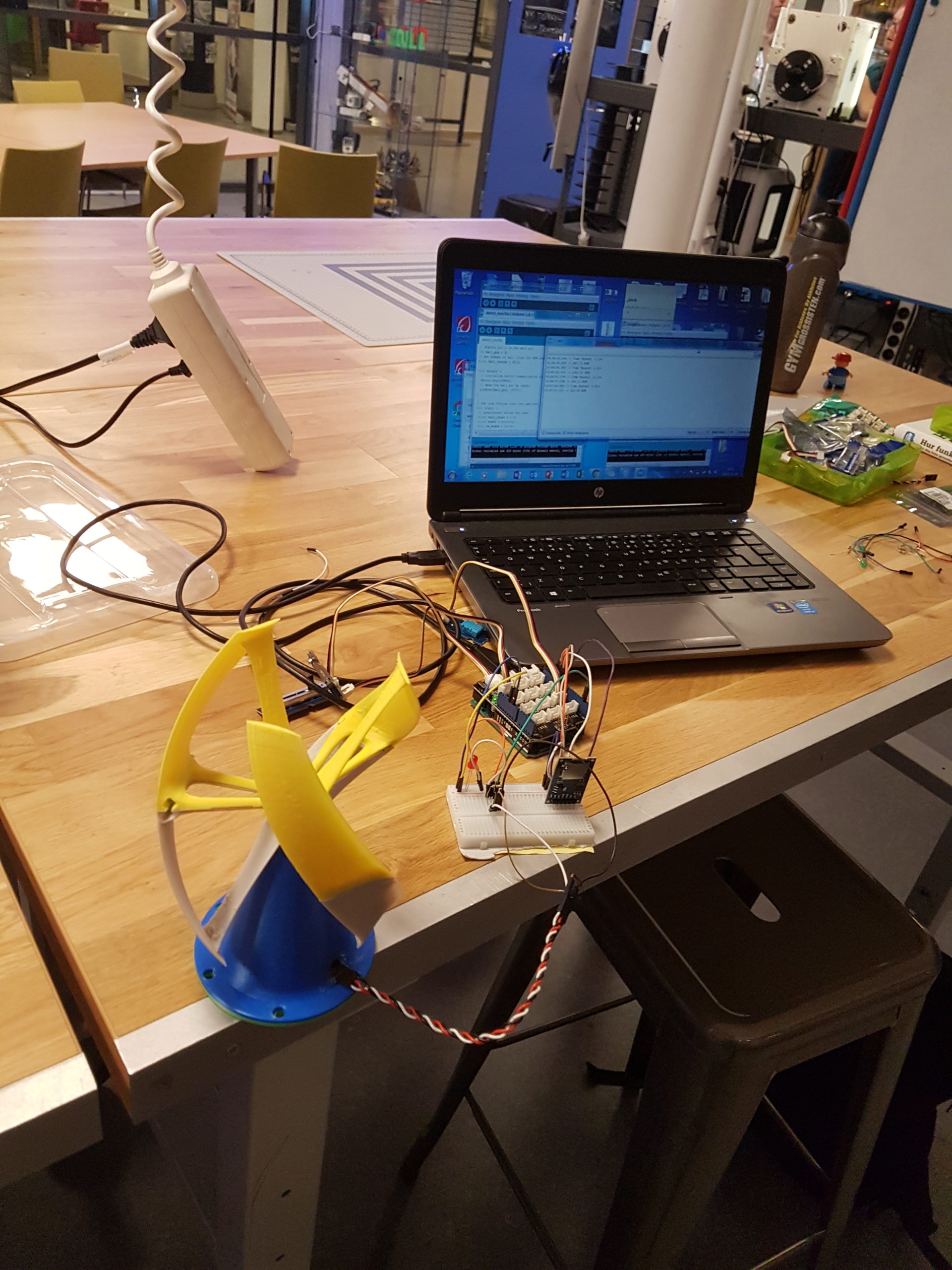

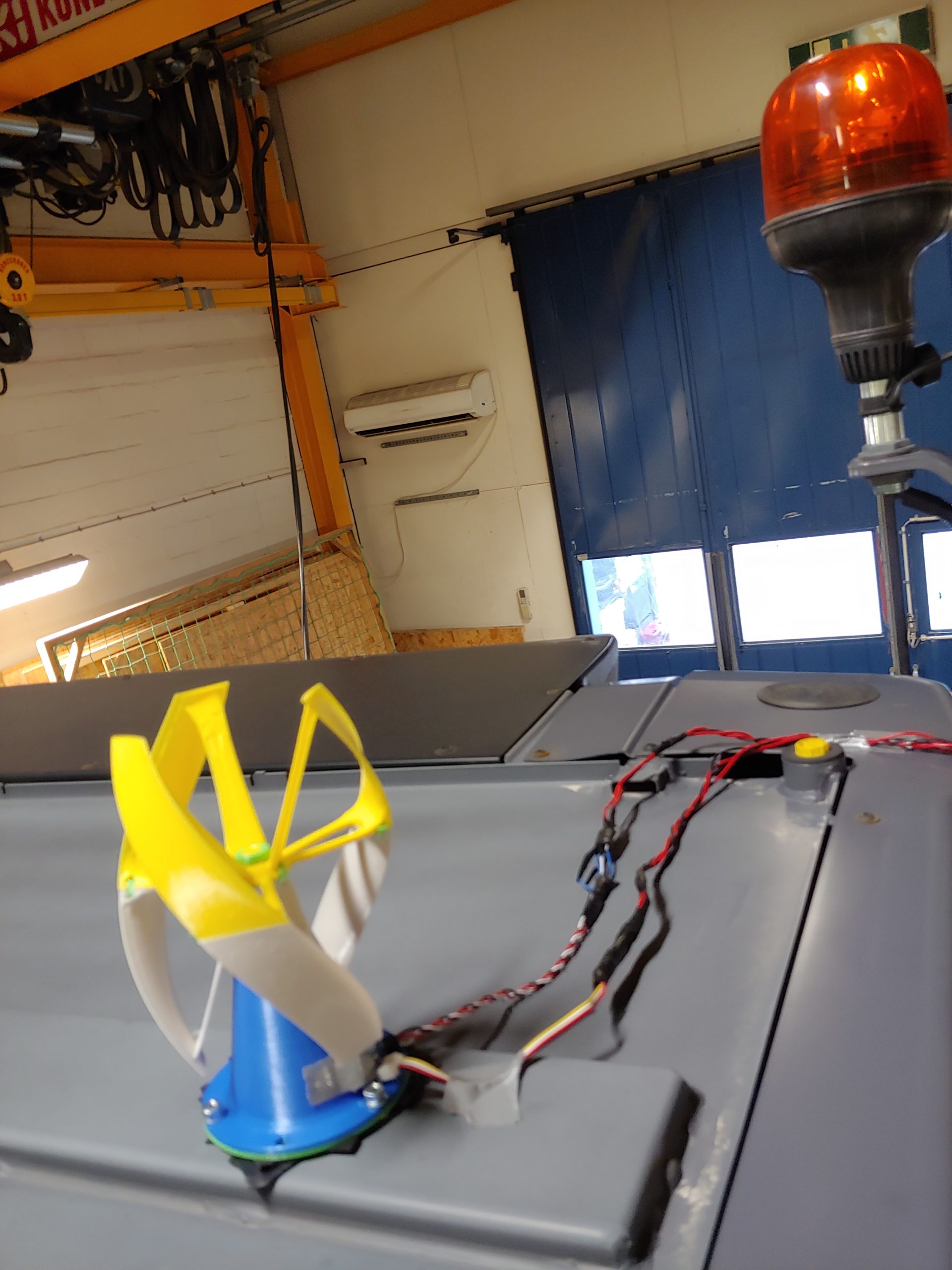

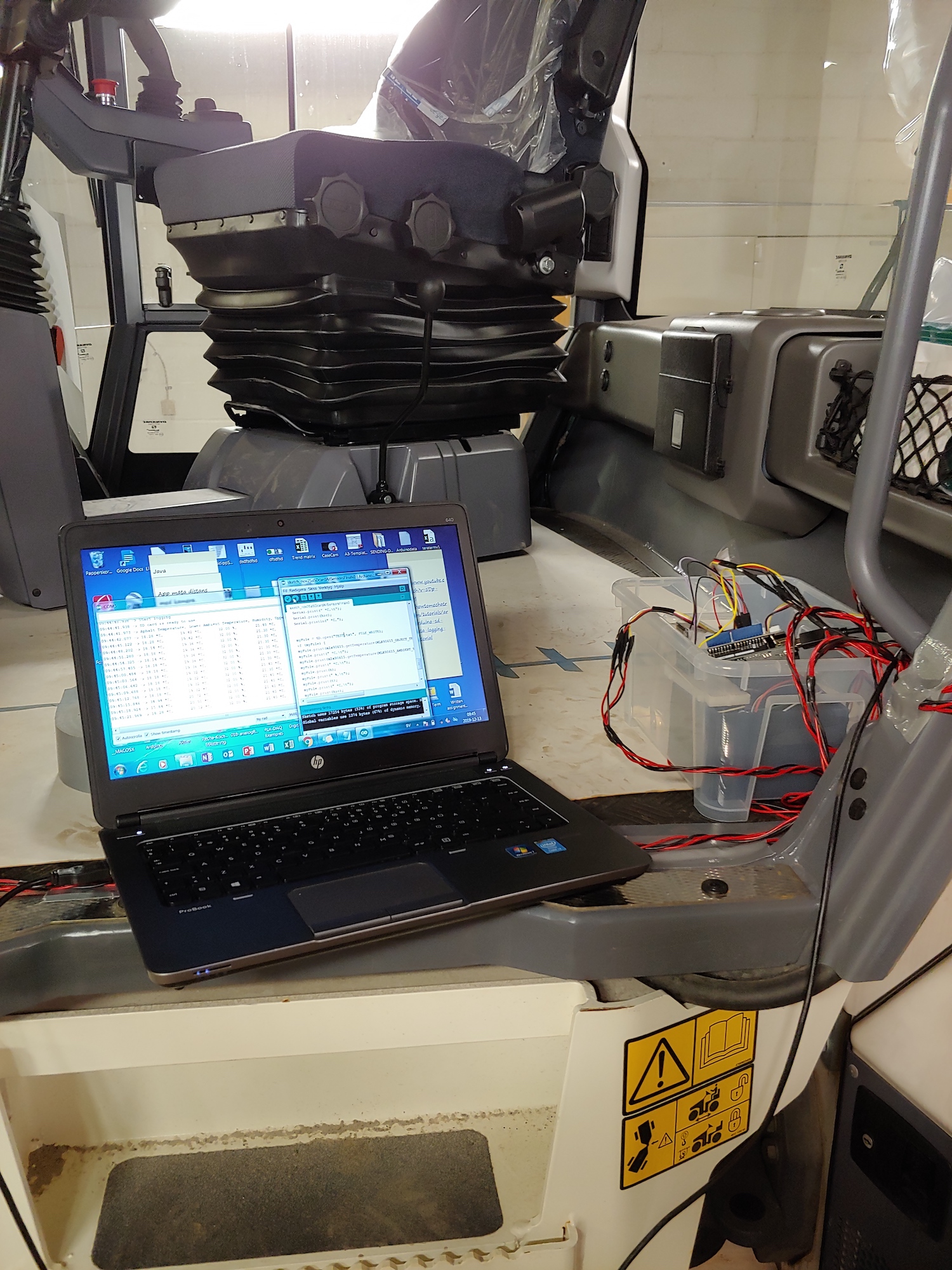

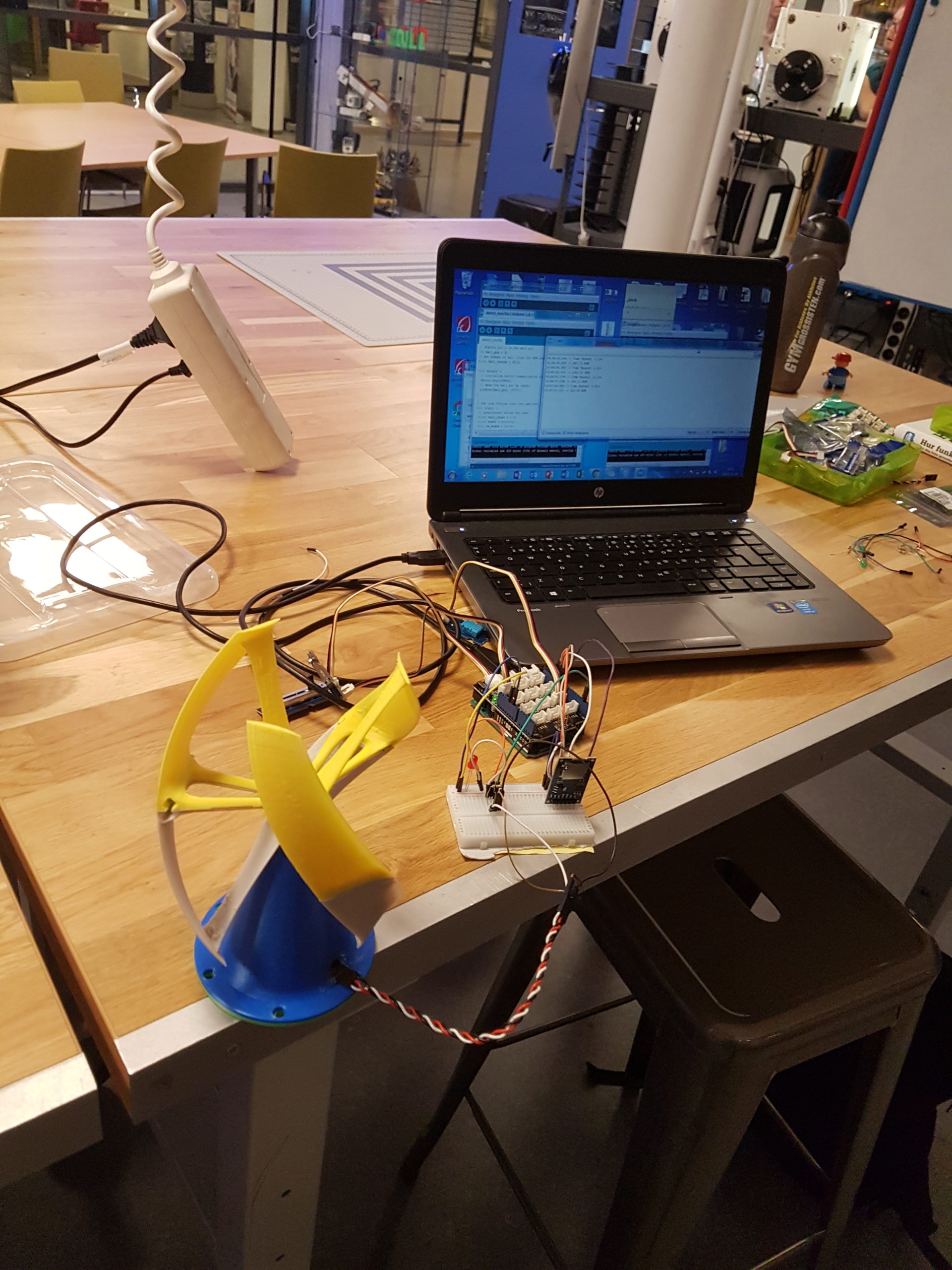

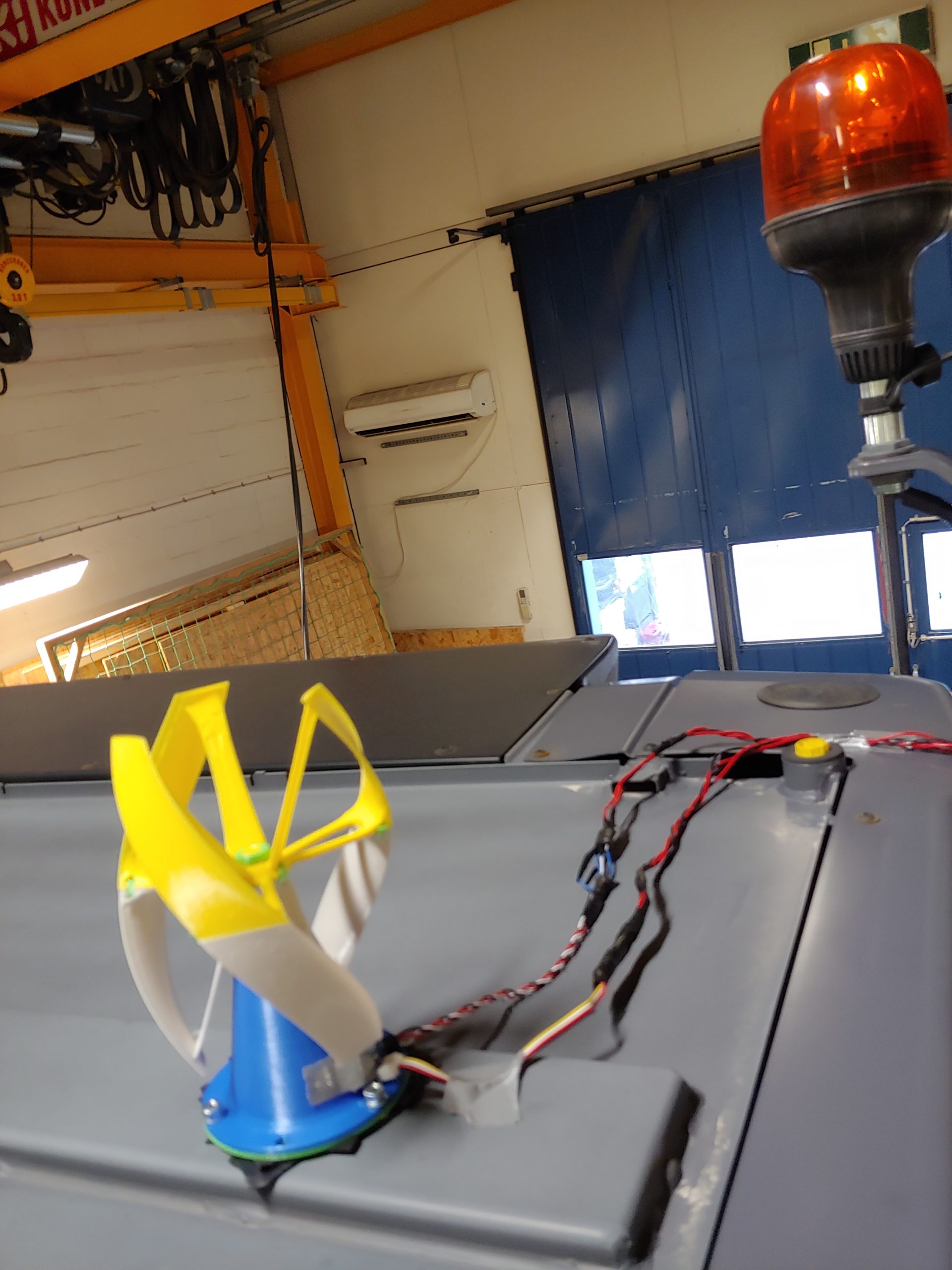

With Arduino we built a sensor gathering package which measure drum temp., ambient temp., humidity, asphalt temp., wind speed and then store the data on a SD-card. A turbine was build with 3D printing to measure wind speed with a hall sensor. Applied it on a real roller to get some real data sets. Learnt about Arduino and that more data sets in different scenarios would be useful.

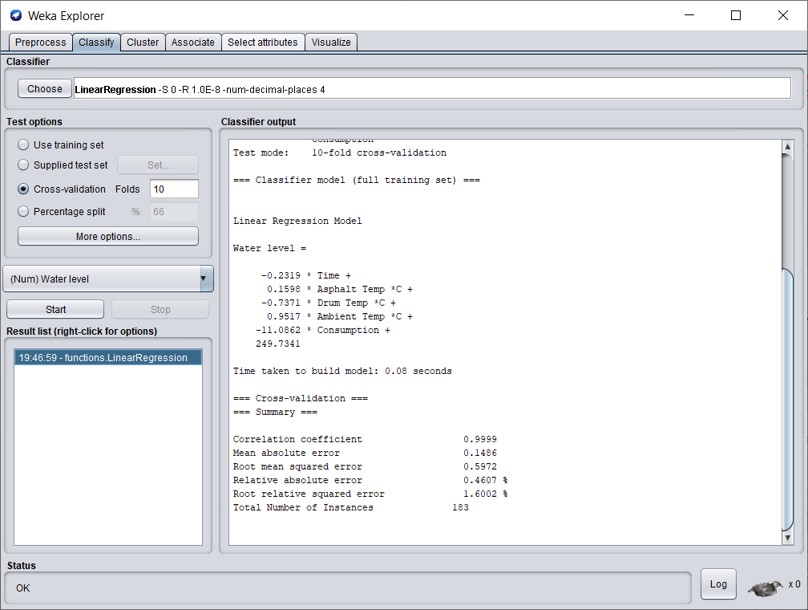

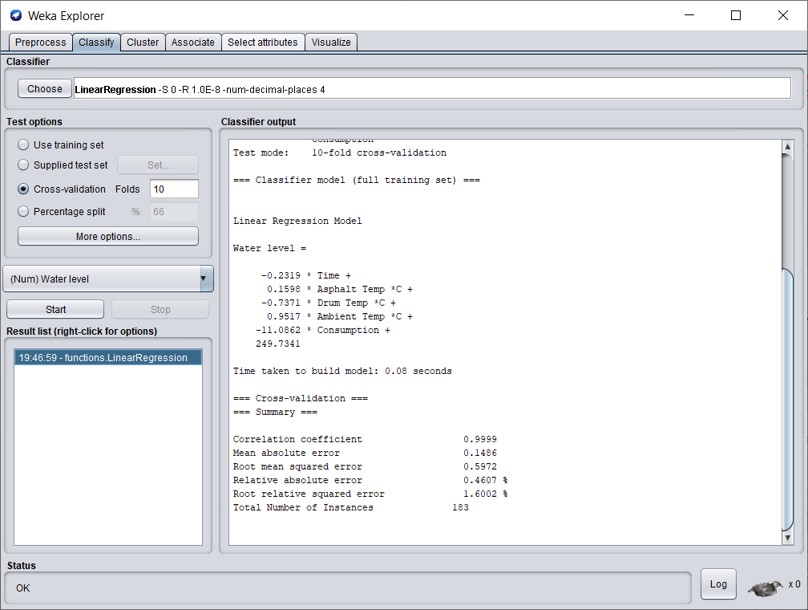

Did data analysis through Weka and excel, used weka to have a basis for doing a prediction through linear regression in excel. Excel allows for input of square meters to calculate the water needed for a specific job. Learnt more about the programs and how it works with performing predictions from some available data sets.

Quotes from sponsor/partner: –

Project team:Anton Senbom, MSC in Mechanical Engineering, class of 2014. Bastiaan Hamer, MSC in Mechanical Engineering, class of 2014. Philip Axelsson, MSC in Mechanical Engineering, class of 2012. Fatme Al, MSC in Mechanical Engineering, class of 2015.