Digital Twin

- Post by: Tobias Larsson

- 19th January 2020

- No Comment

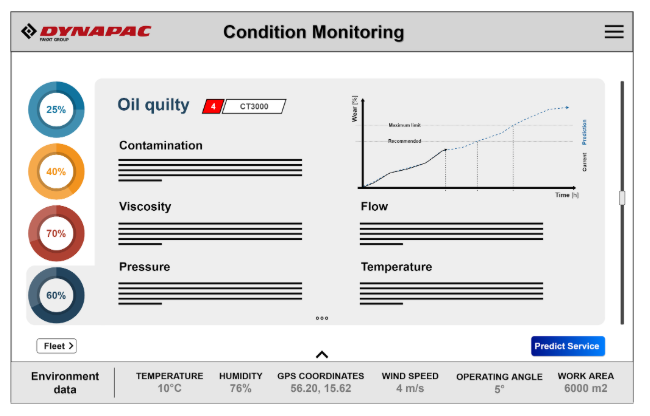

Predictive maintenance of hydraulic oil

Programme: 2015 Master in Mechanical Engineering – Innovative and sustainable product development

Course: MT2556, Extreme Product-Service Innovation

Corporate partner: Dynapac

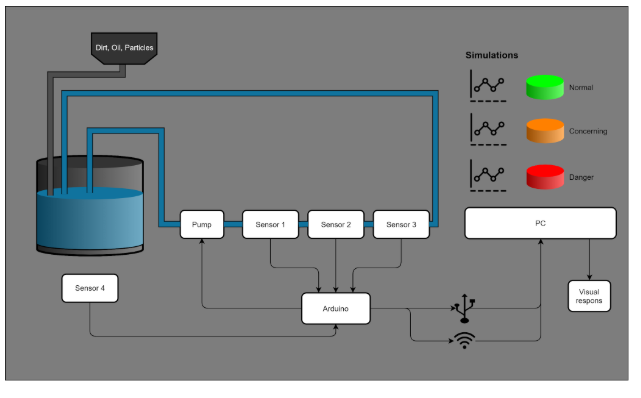

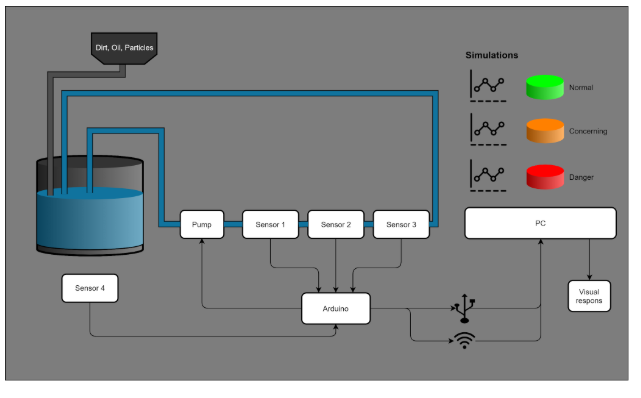

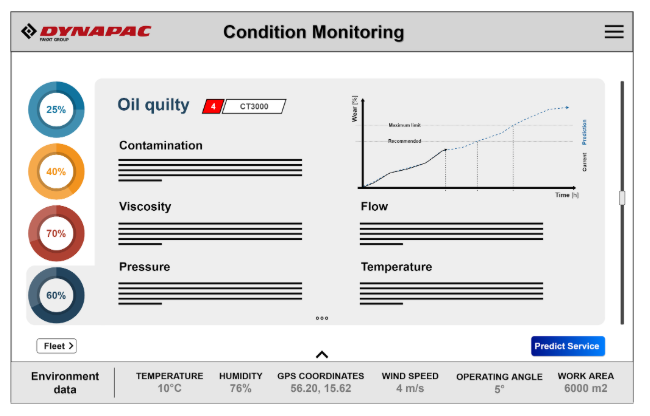

Challenge: The world is facing a shift towards an industrial revolution called industry 4.0. Manufacturing companies are preparing to migrate to this technical advancement, some more willingly than others, hoping to gain new values and offerings. Currently, Dynapac is evaluating the implementation of Digital Twin and its possibilities. Furthermore, the outcome was divided into a concept and a prototype. The concept describes the broader aspect through the mapping of the proposed system and its offerings, in the future. Whilst the prototype showcased the possibility of gathering sensor-data and making simulations of a Digital Twin for the hydraulic system.

Solution: The world is facing a shift towards an industrial revolution called industry 4.0. Manufacturing companies are preparing to migrate to this technical advancement, some more willingly than others, hoping to gain new values and offerings. Currently, Dynapac is evaluating the implementation of Digital Twin and its possibilities. Furthermore, the outcome was divided into a concept and a prototype. The concept describes the broader aspect through the mapping of the proposed system and its offerings, in the future. Whilst the prototype showcased the possibility of gathering sensor-data and making simulations of a Digital Twin for the hydraulic system.

Impact: The main advantage of Digital Twin is the ability to use historical and current data to predict future events. Thereby, Predictive Maintenance, enables real-time condition monitoring for better machine care and control, simulating recommended service with the option for scheduling that service and ordering parts ahead of time. Thus, eliminating dead time and increasing work efficiency.

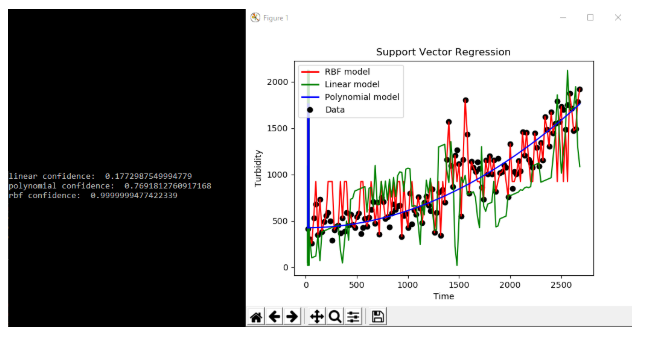

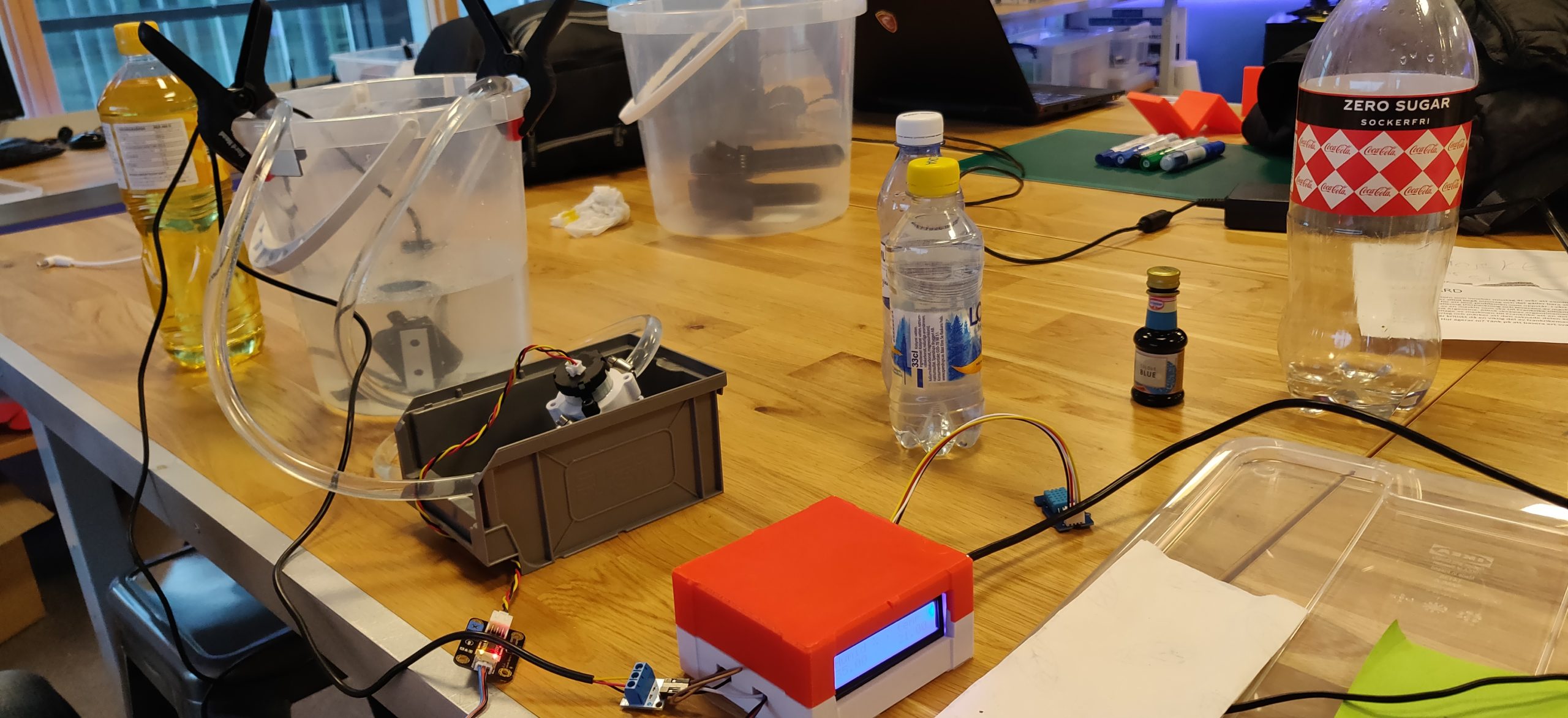

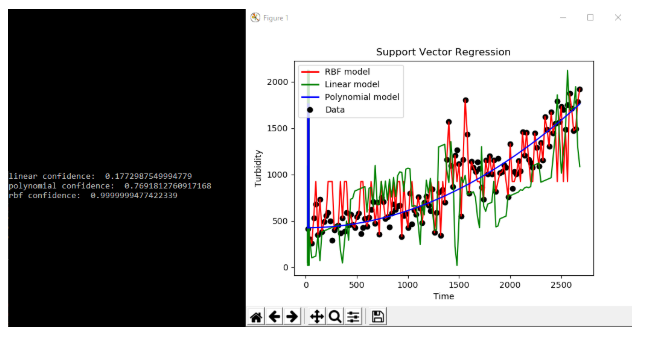

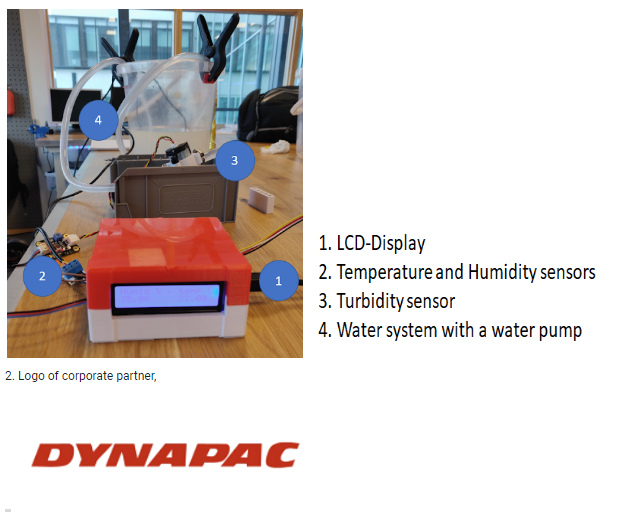

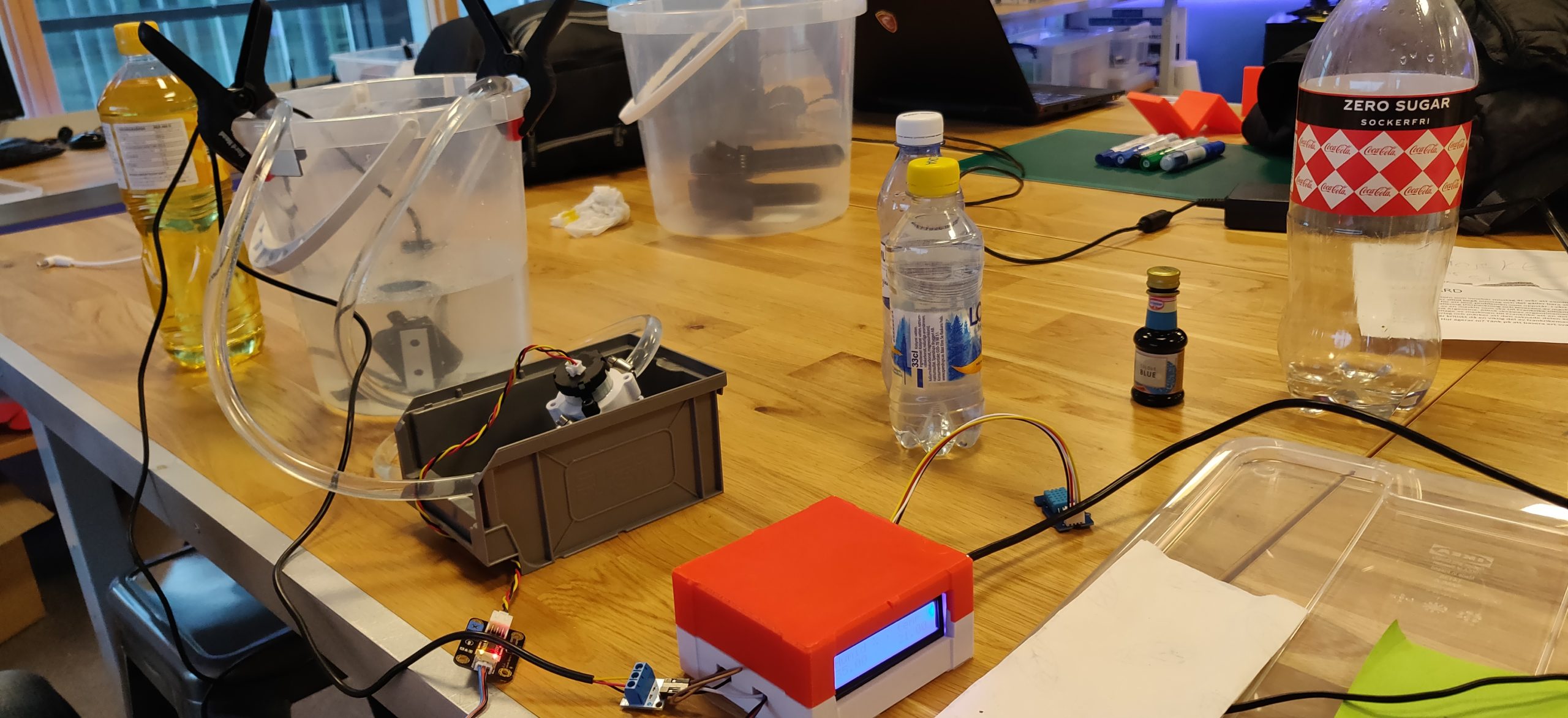

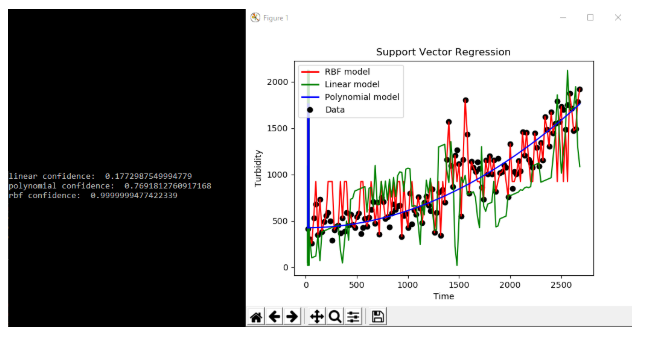

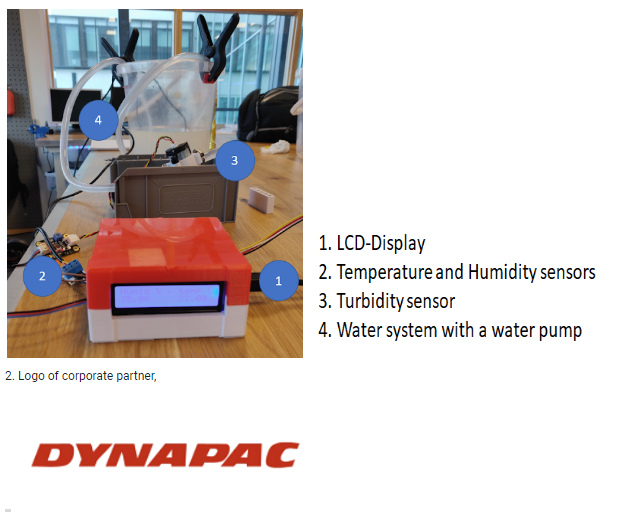

Prototypes: We decided to simulate a hydraulic system through creating a similar setup that uses water instead. This was controlled through arduino which also gathered all data from the sensors. The sensors were measuring water temperature, surrounding humidity, surrounding temperature and turbidity. 3D-printing were used to create attachments for the sensors. Those sensor data was later used to train a machine learning algorithm to be able to predict the future turbidity of the water.

Quotes from sponsor/partner: The partners (Dynapac) were pleased with the concept and the results. They hadn't developed any concept themselves so they were unsure of why they need a digital twin and thought we presented a positive result.

Project team: Andreas Andersson, Mathias Petersson, Mustafa Al-shuwaili, Abrahim Abdulkarim, MSC in Mechanical Engineering