Zero emission Roller of the future

- Post by: Tobias Larsson

- 5th November 2018

- No Comment

Product development and innovation of a future roller

Programme: Mechanical Engineering – Innovative and sustainable product development

Course: MT2554

Corporate partner: Dynapac

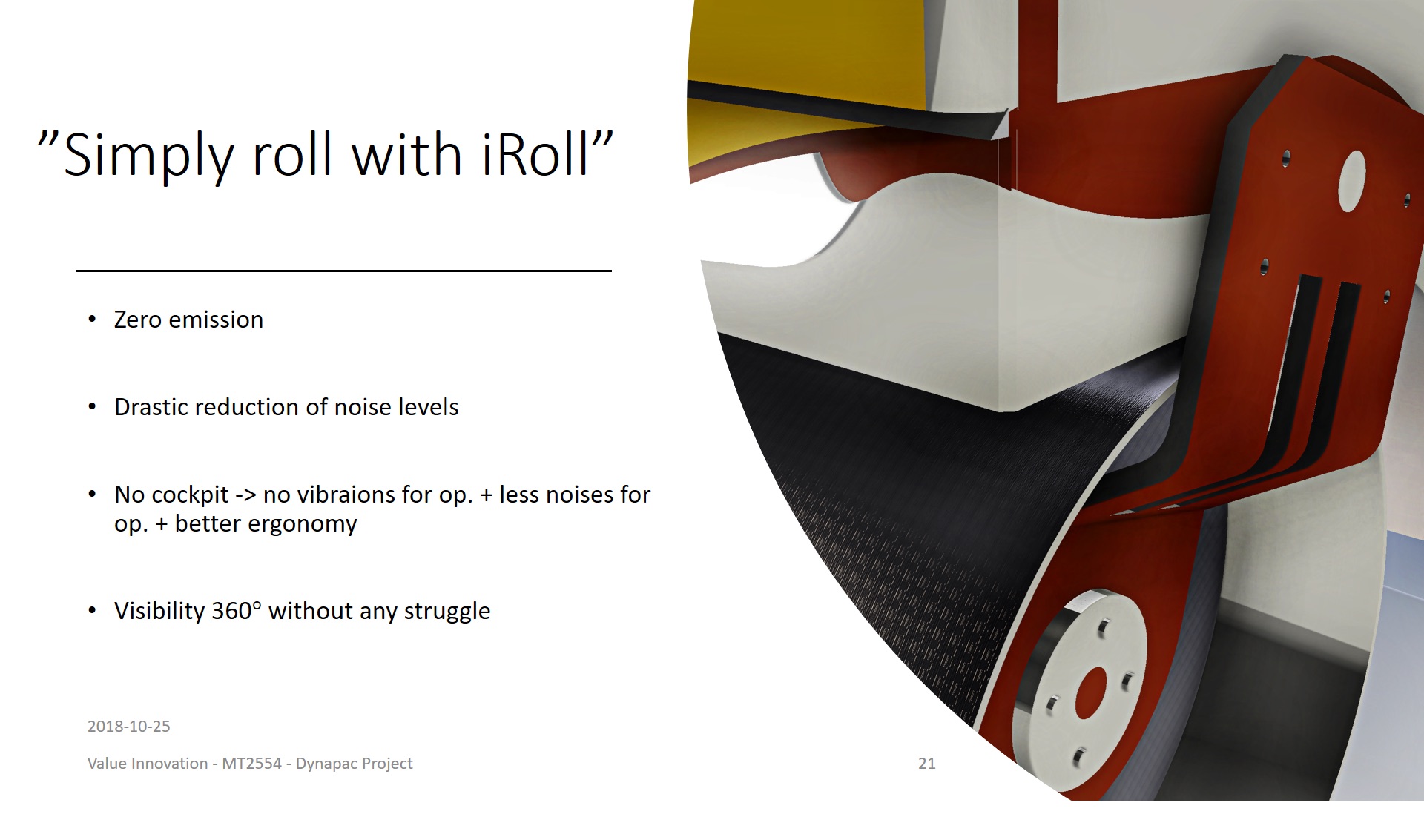

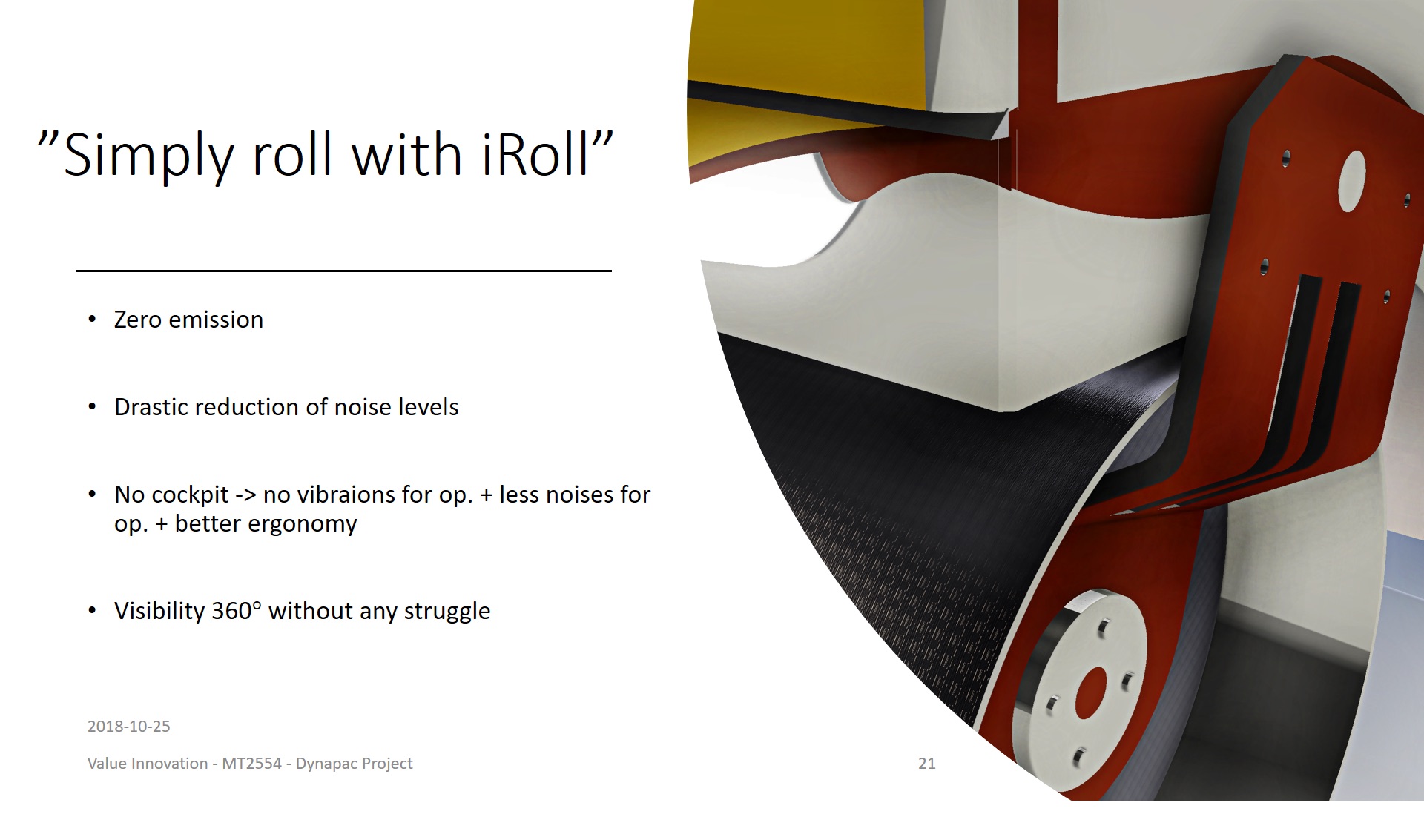

Challenge: Make a roller that has zero emissions, is ergonomic, low sound levels, high visibility and has similar external dimensions as the recent product (CC900).

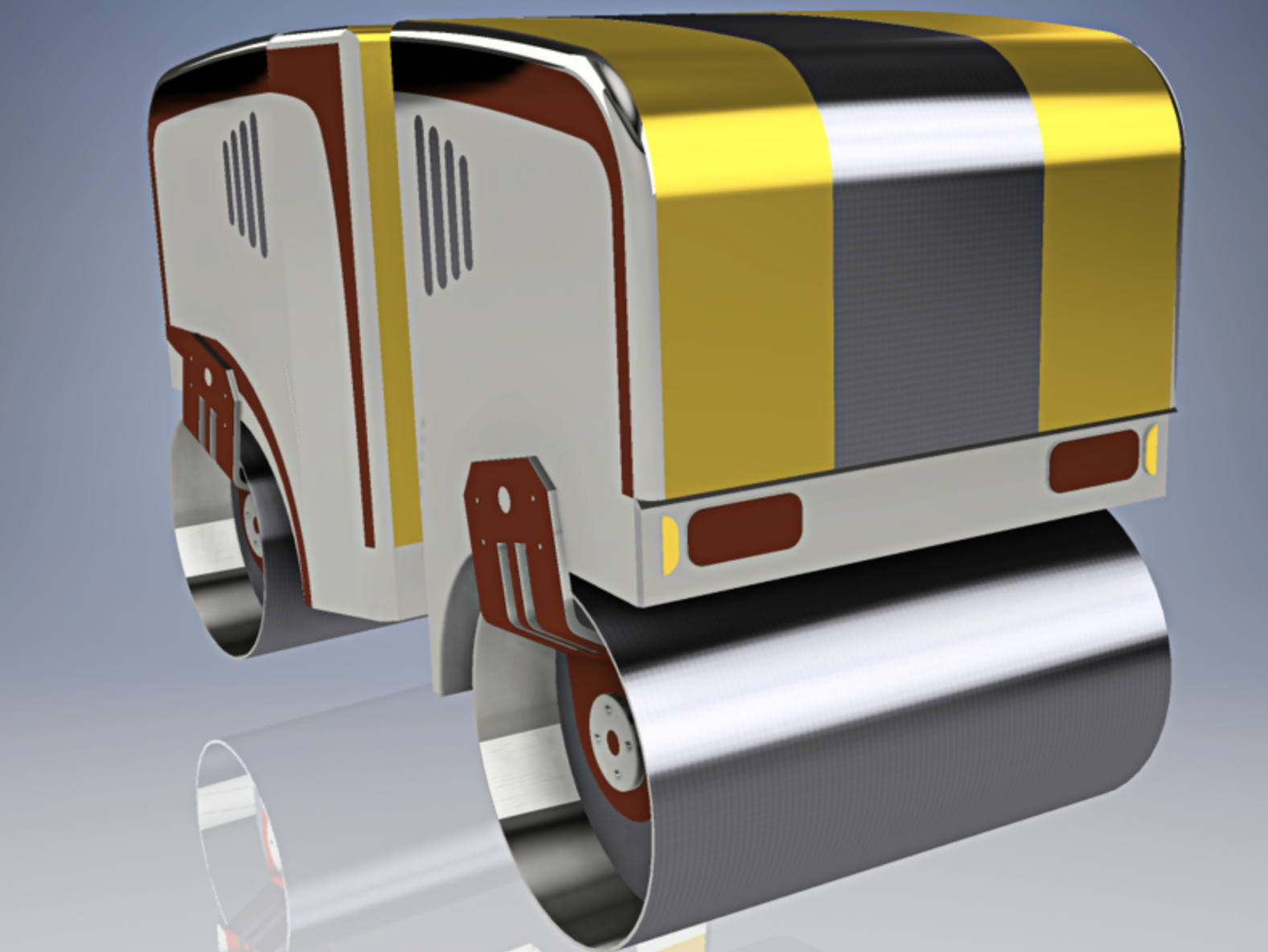

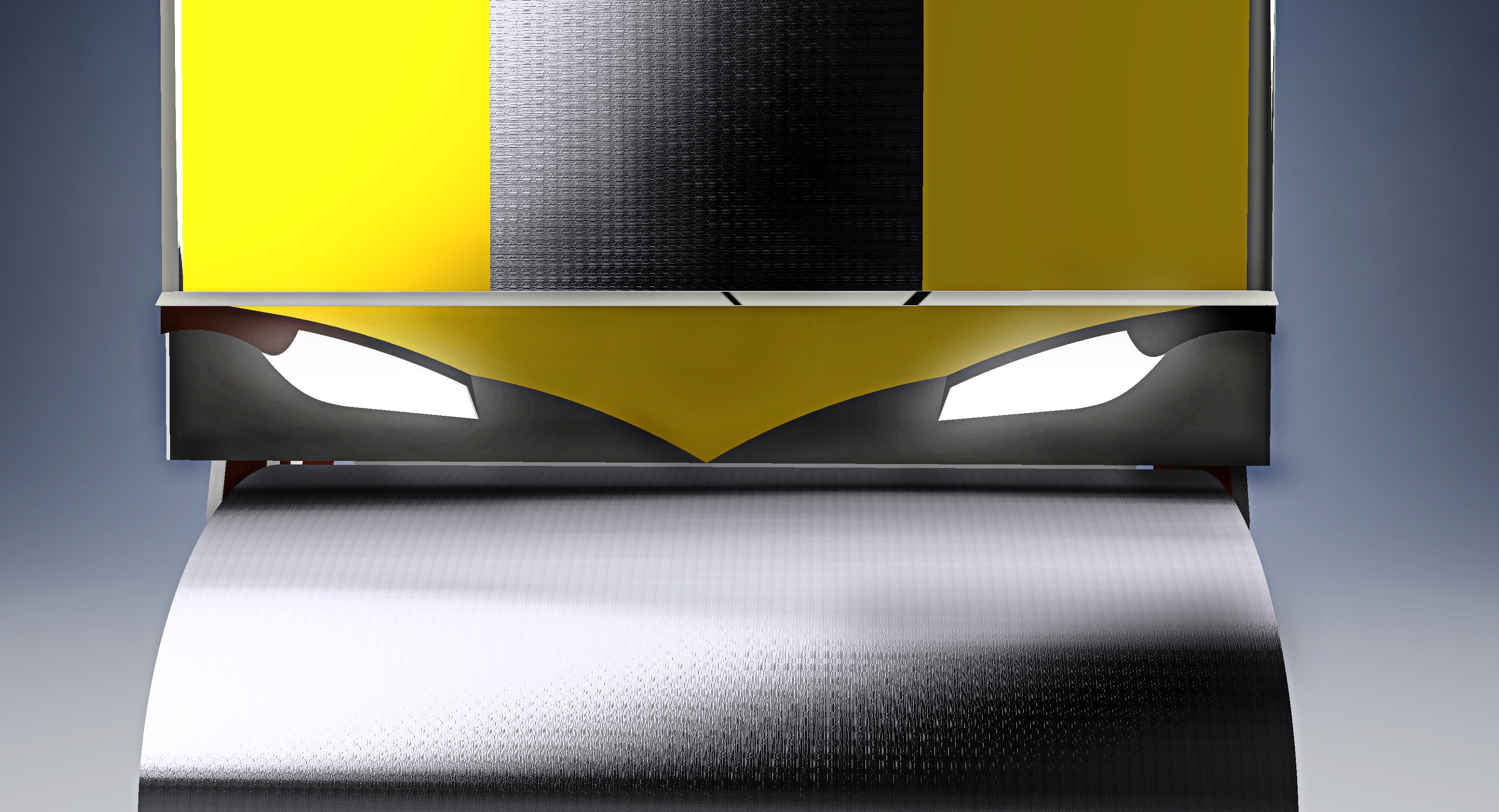

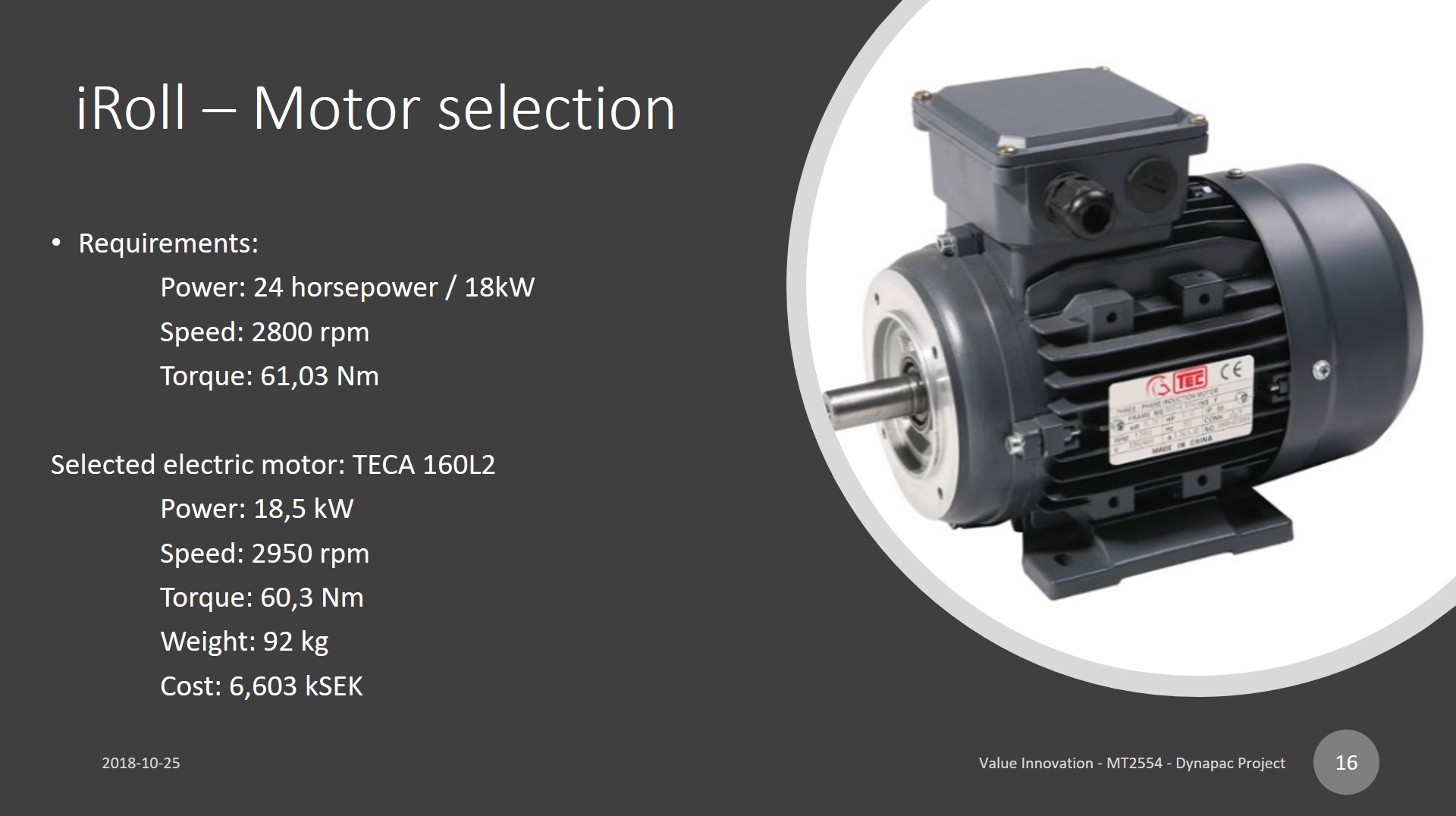

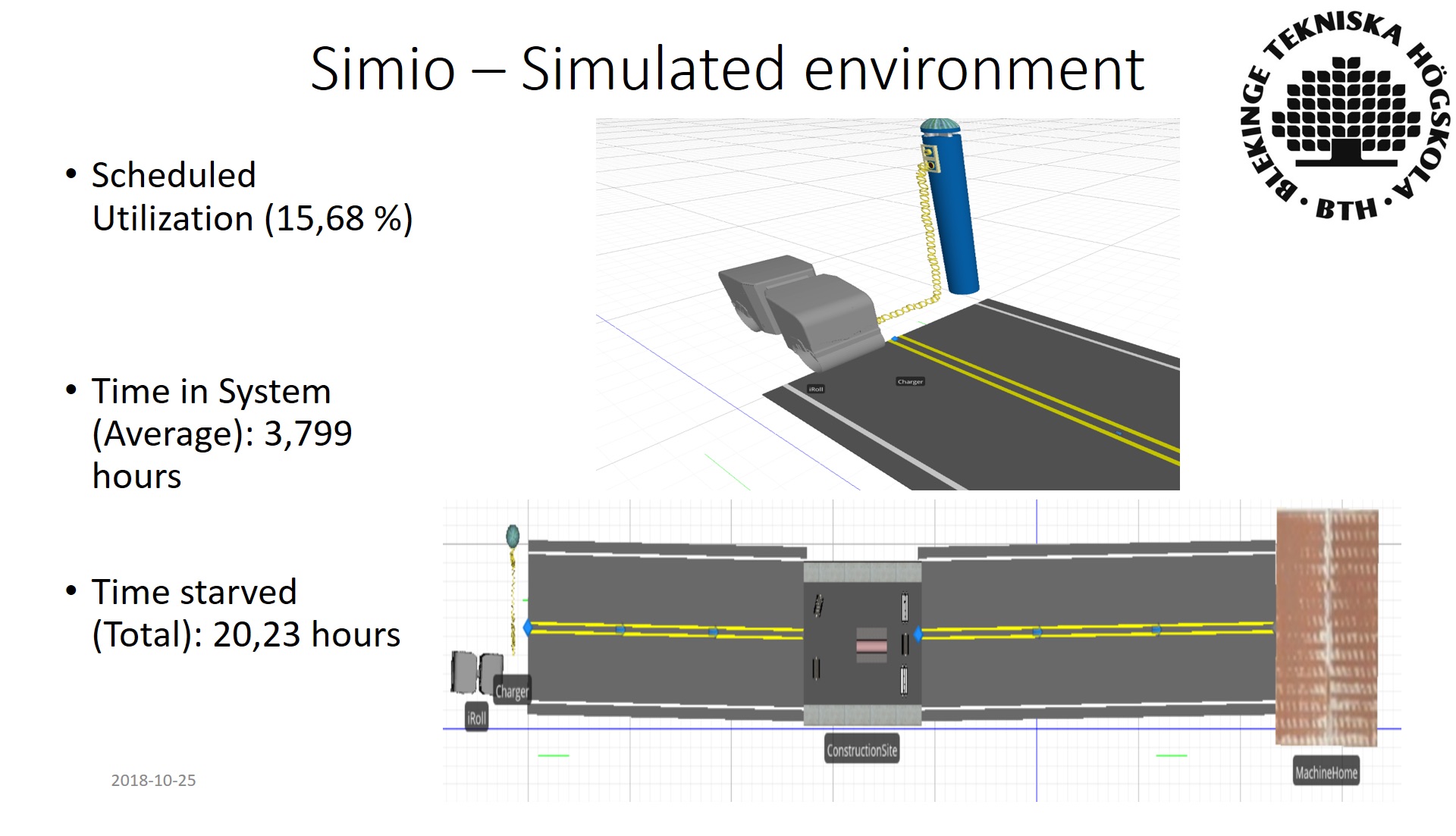

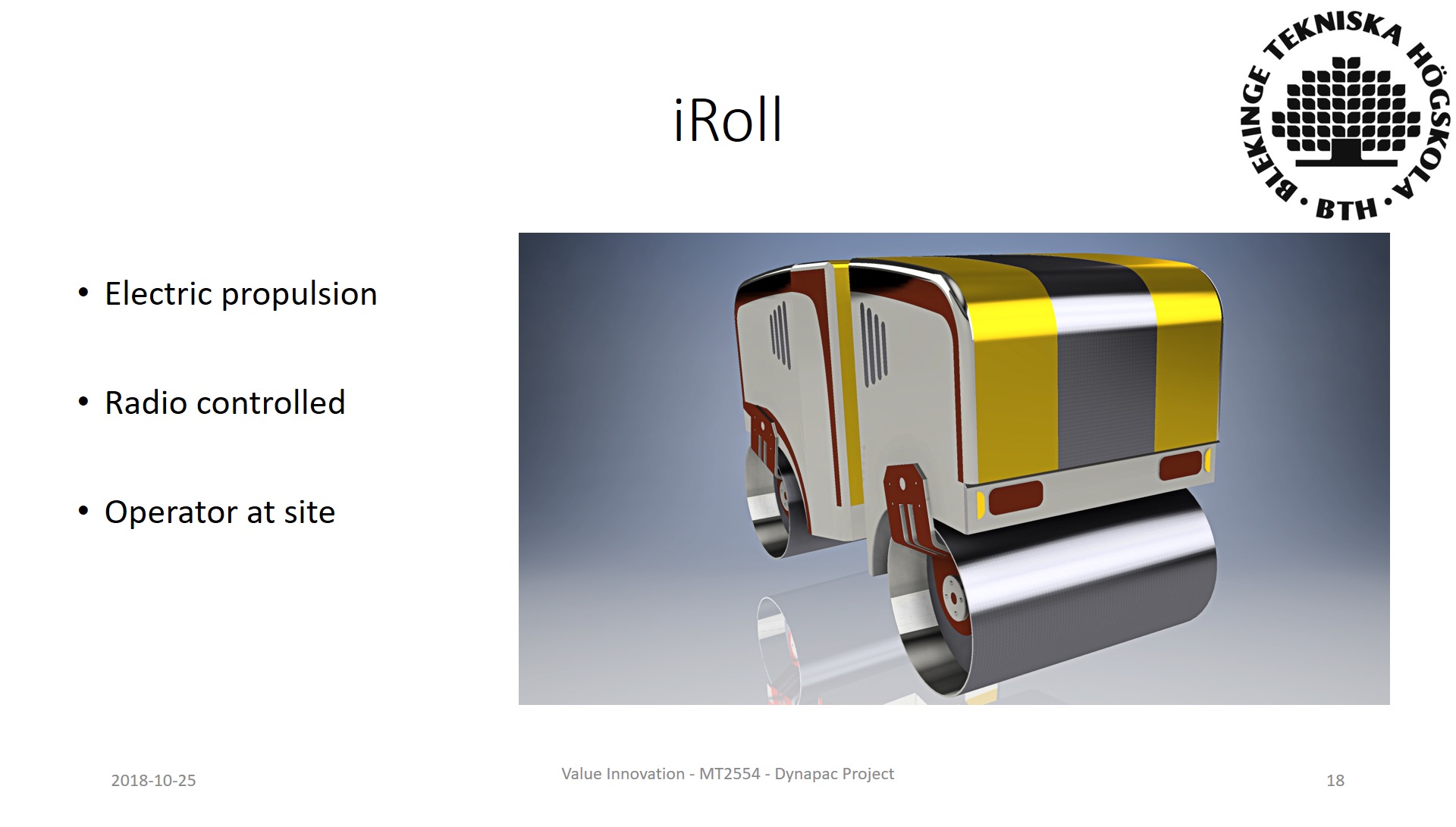

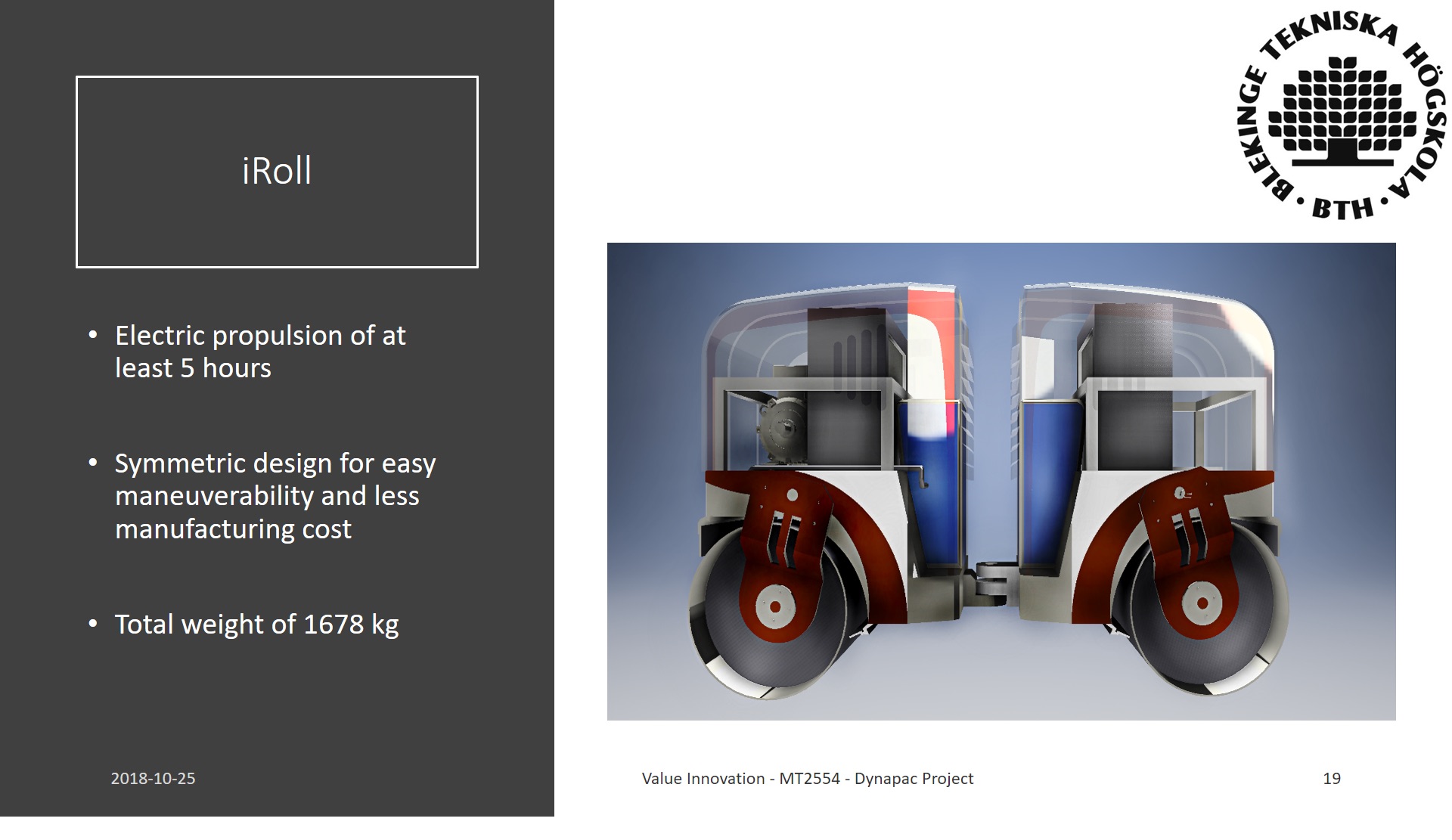

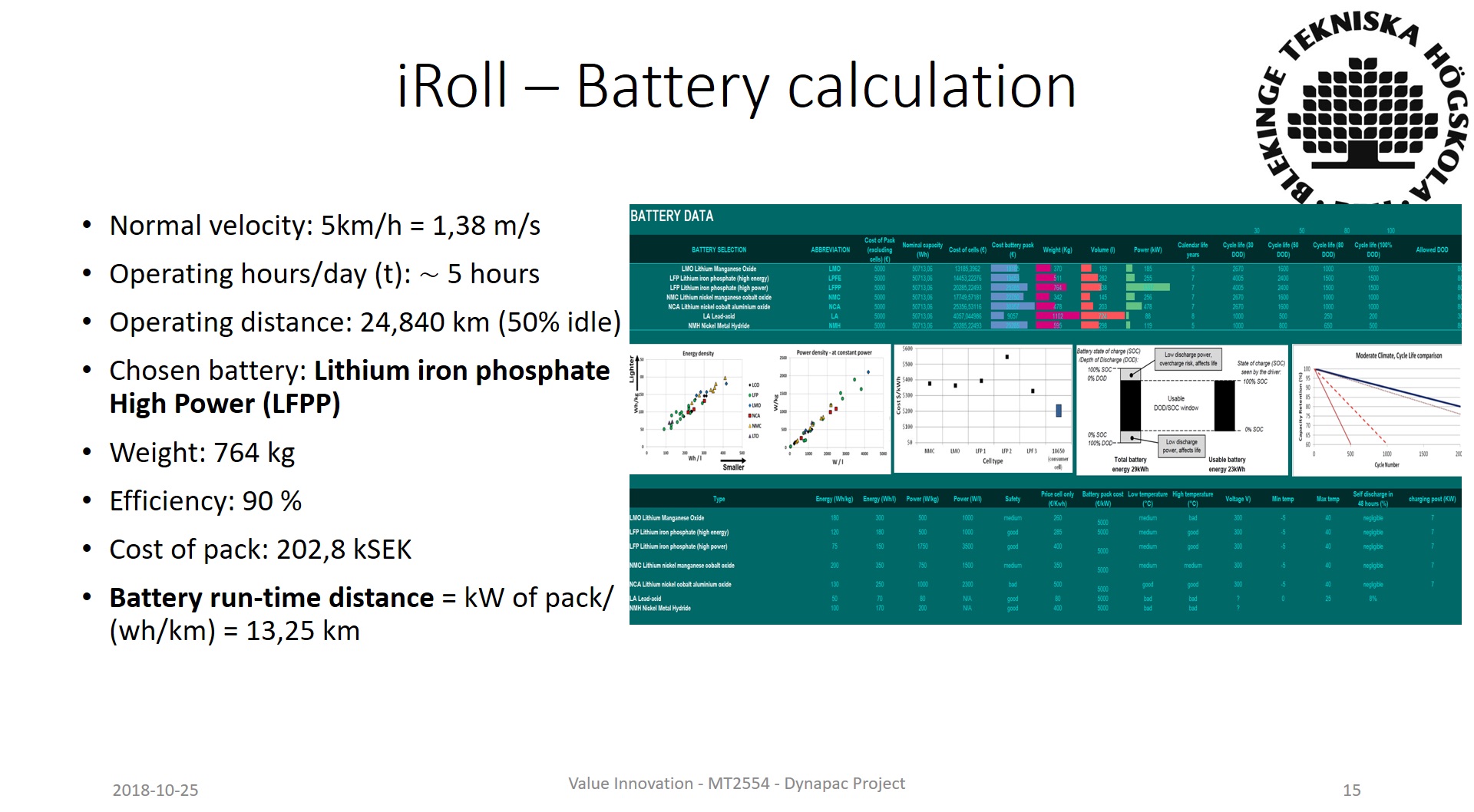

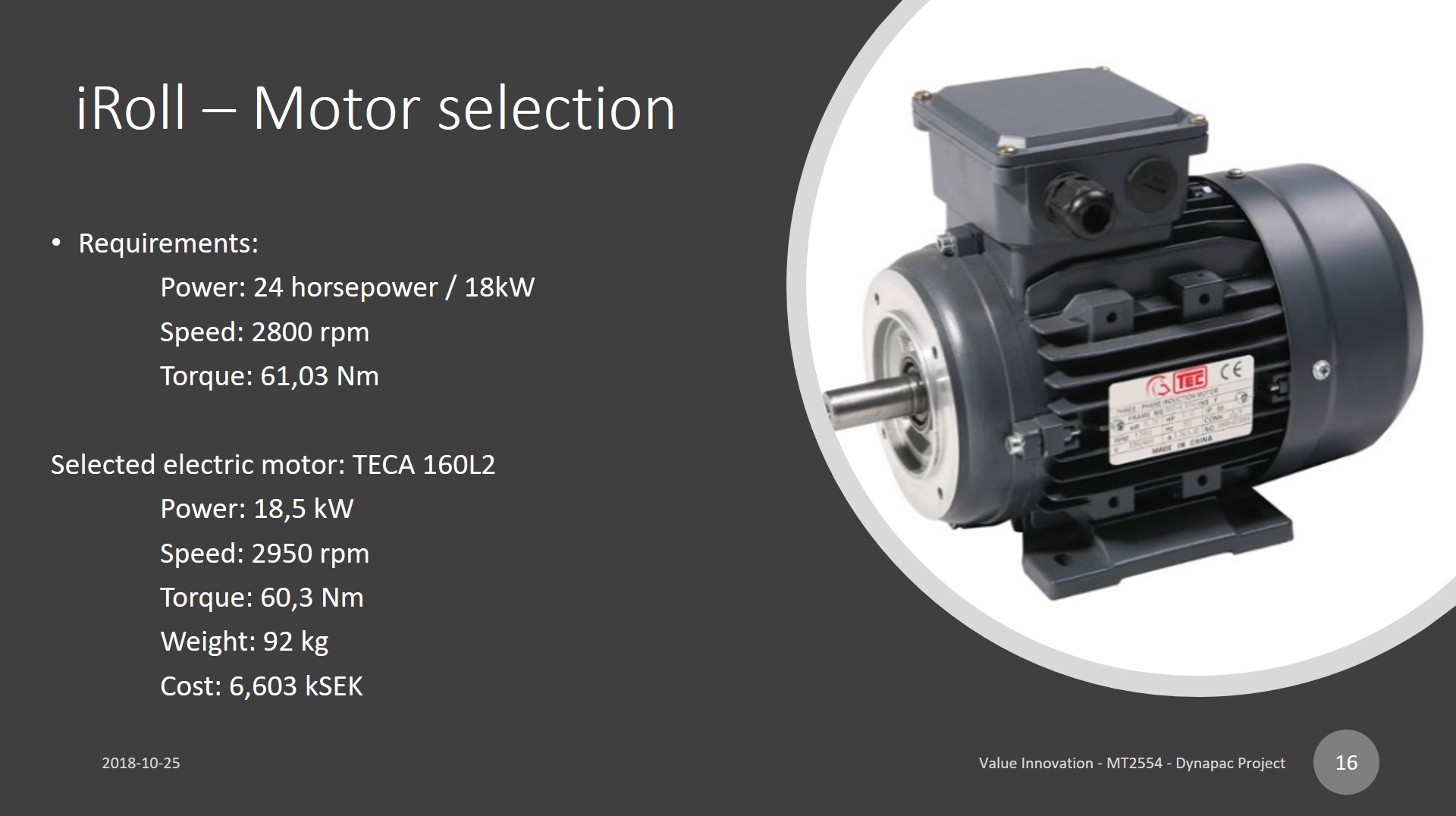

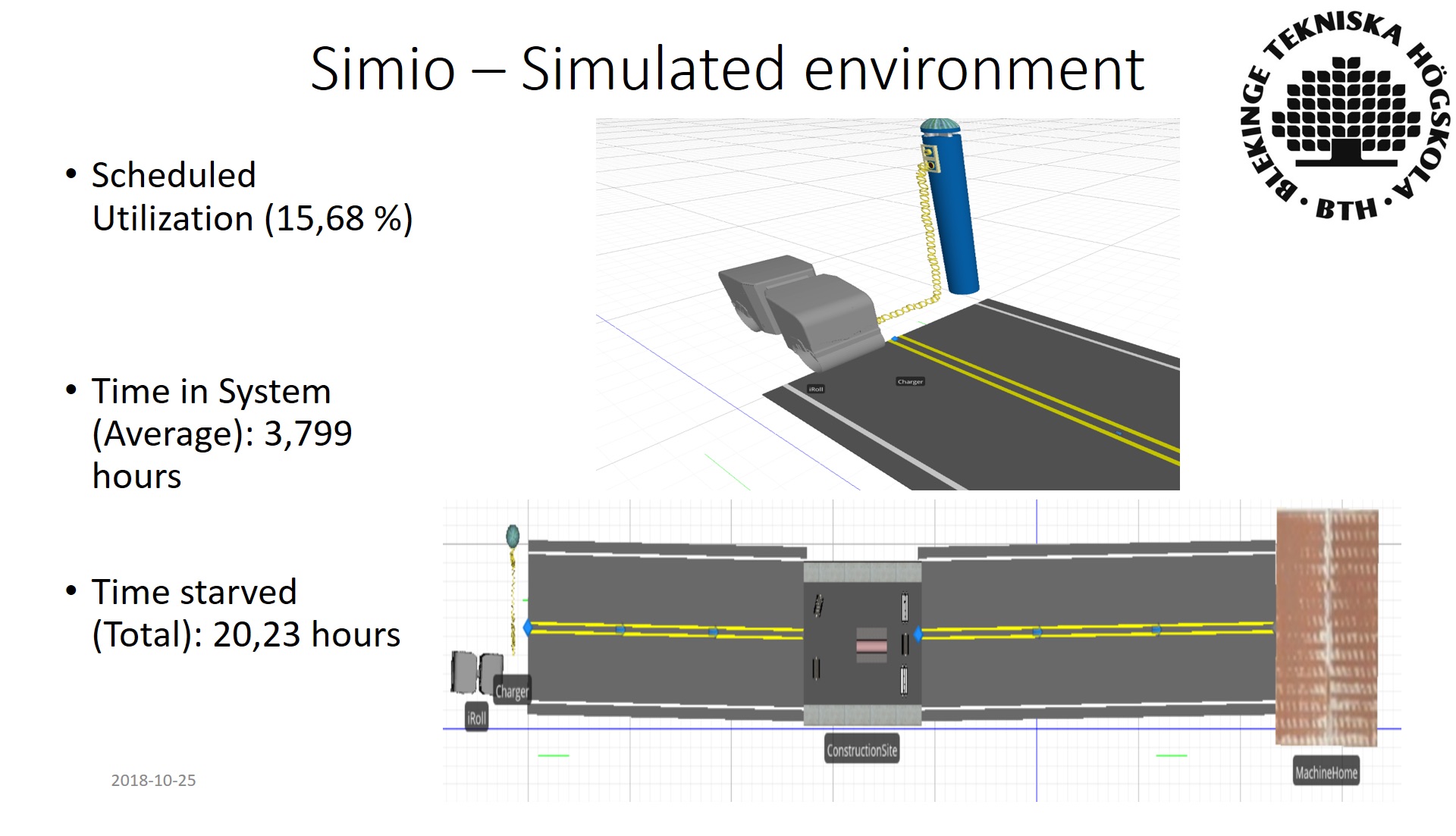

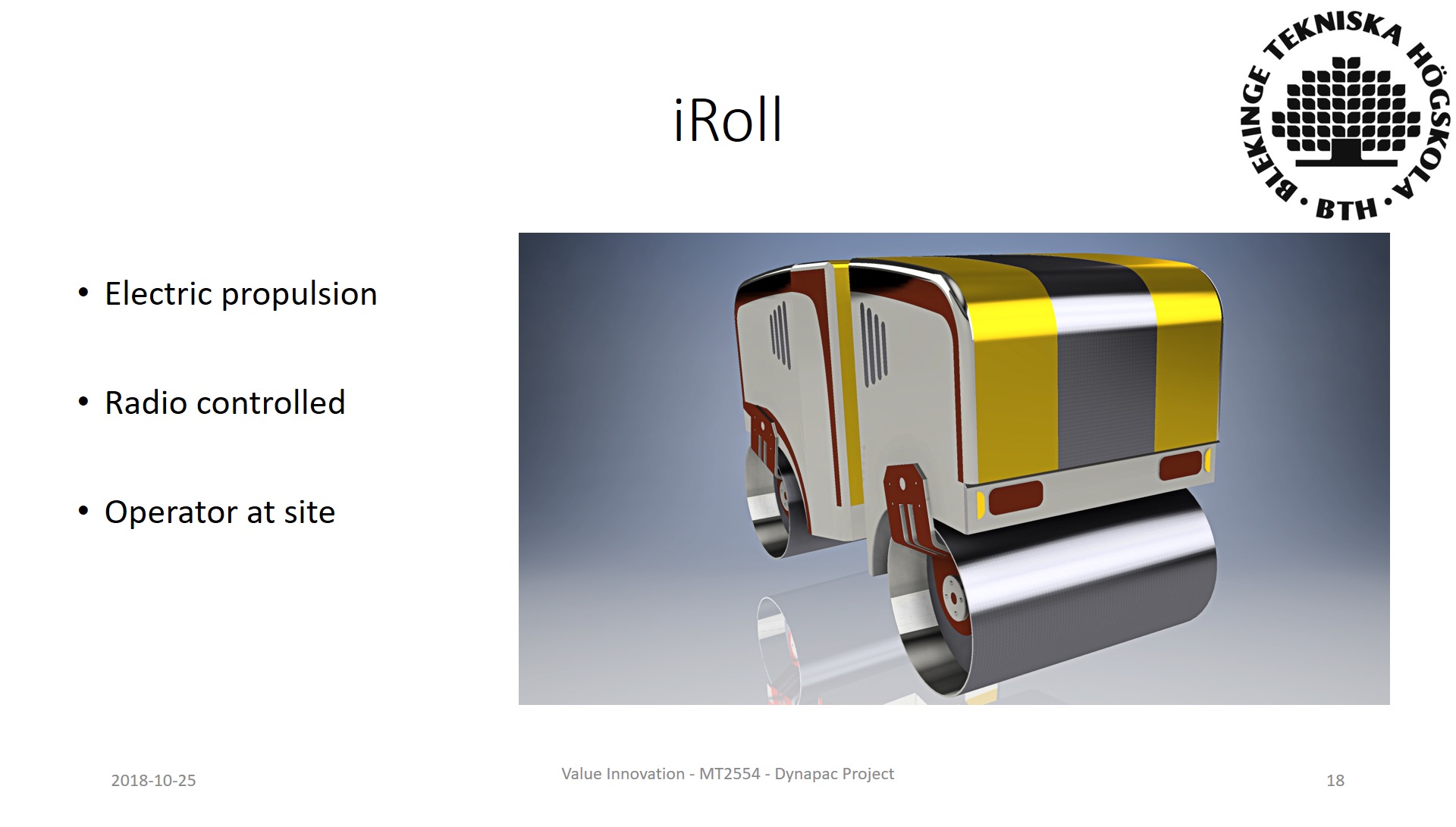

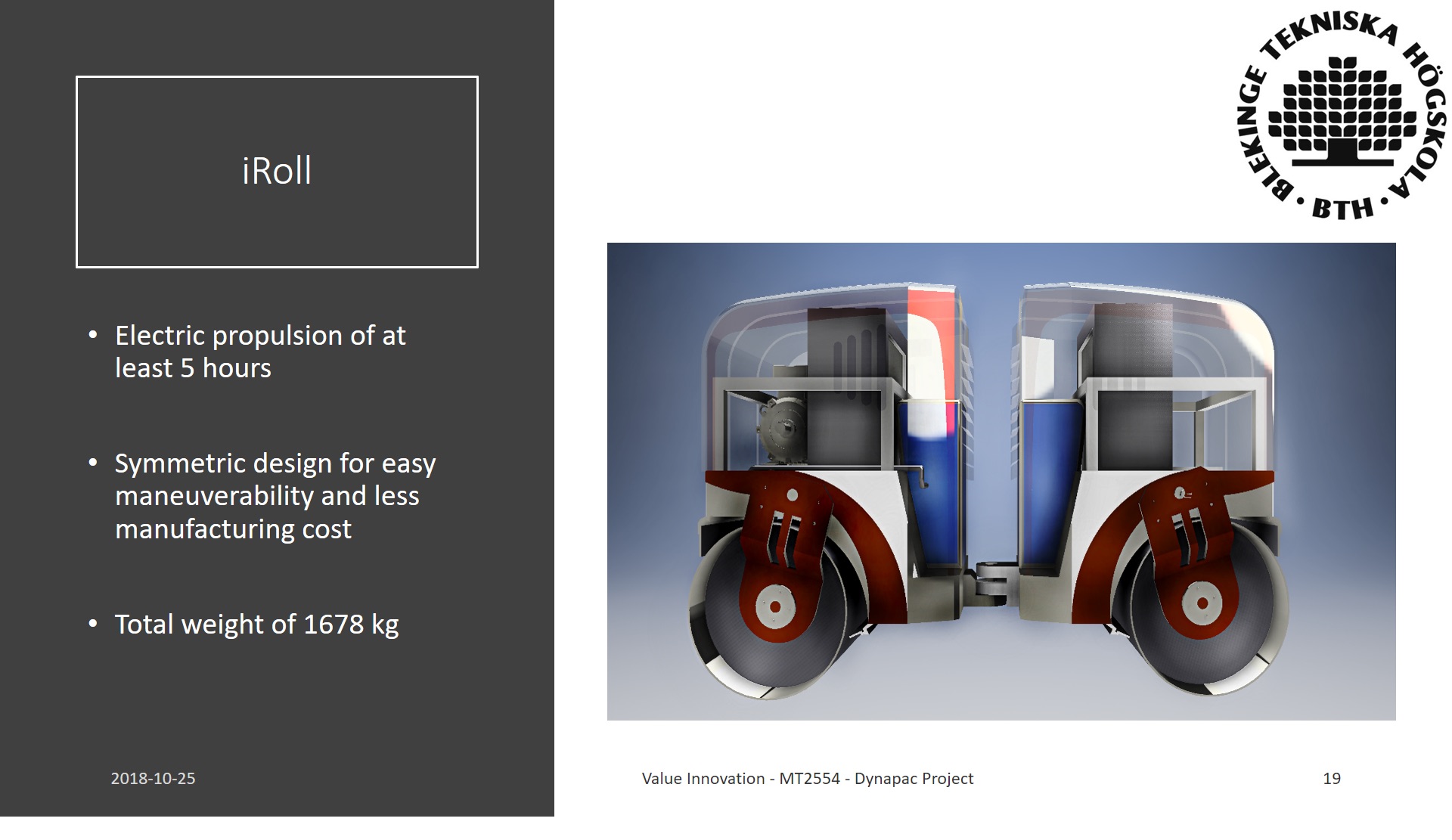

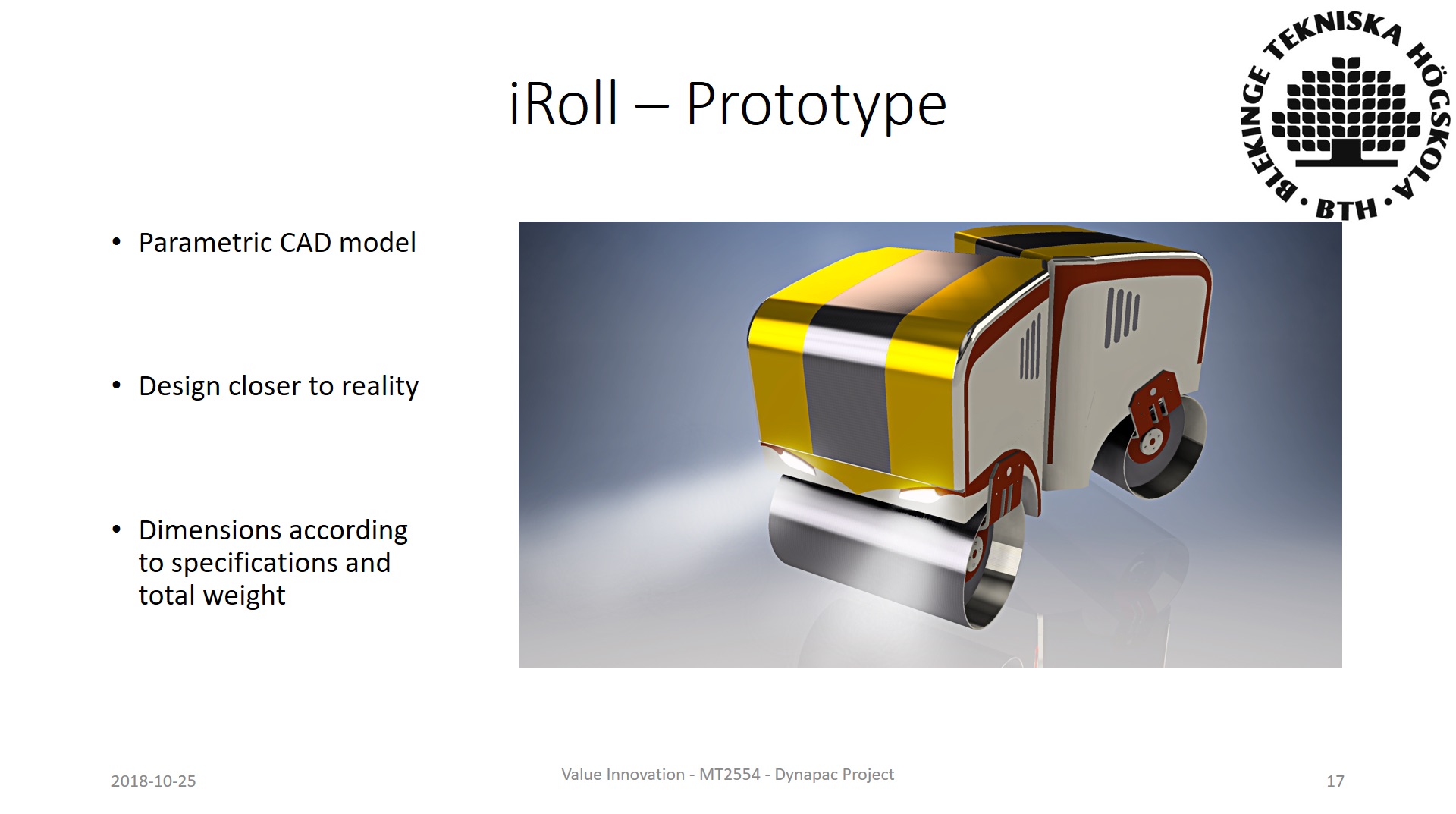

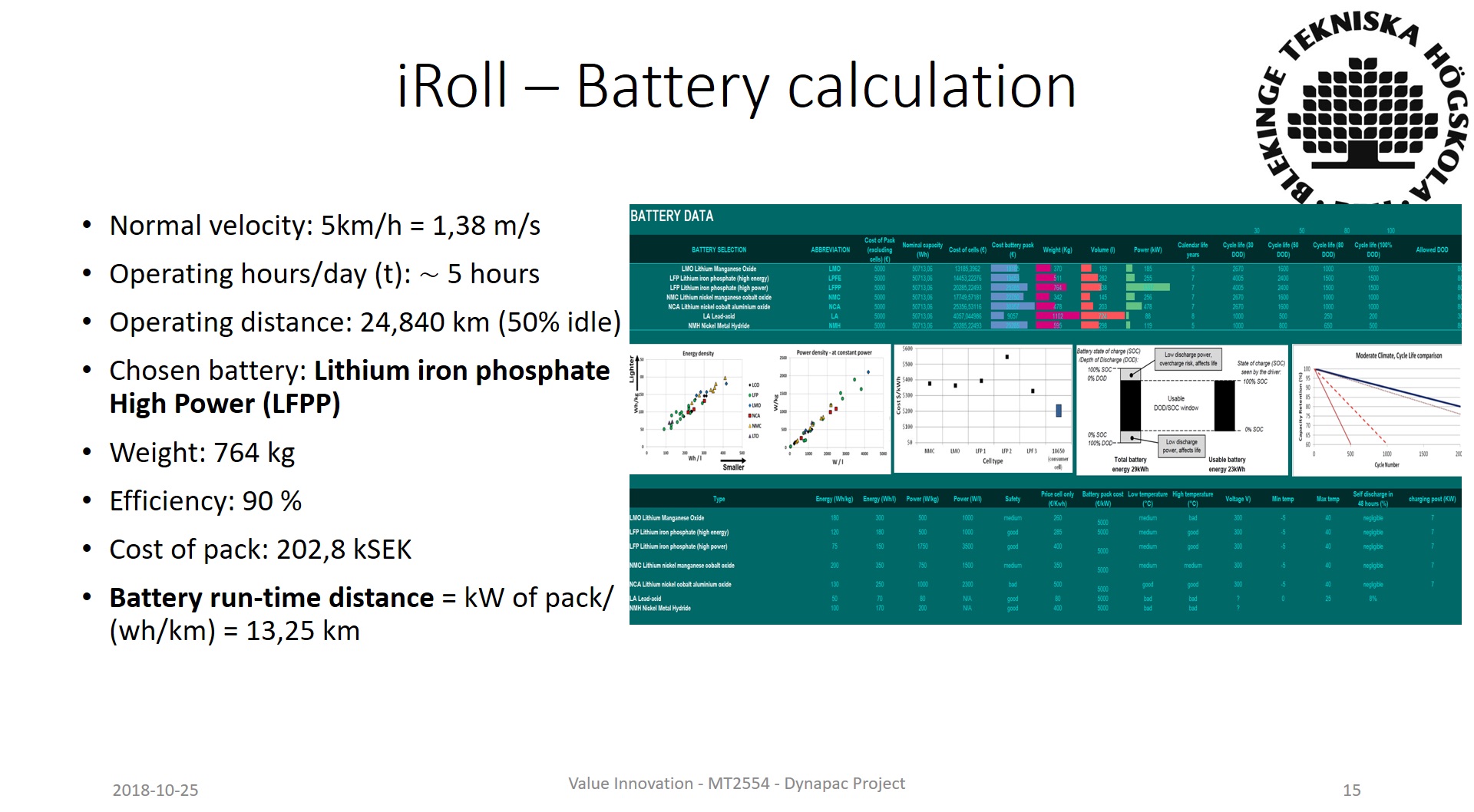

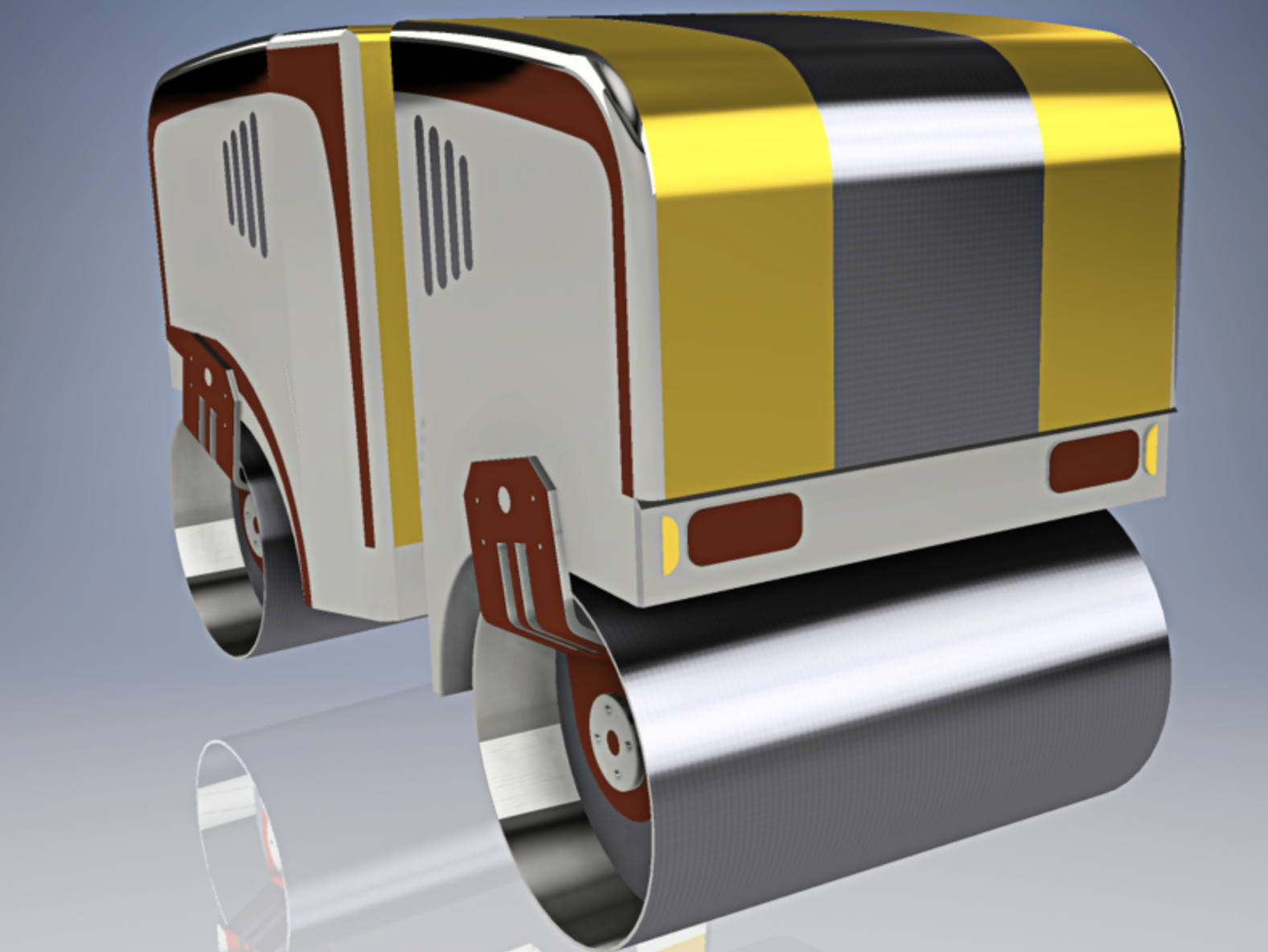

Solution: The solution was an electric compaction tandem roller which is radio controlled at site. A battery was calculated to be Lithium Iron Poshpate with high power, and the electric motor TECA160L2. The solution is called “iRoll", and can compact roads for around 5 hours a day before you need to charge it. The external dimensions and the weight is almost identical with the current product.

Impact: Since it runs on purely electricity, it has zero emission and drastically lower noise levels. The radio control ability also gives a good view for the operator, and he/she can move freely in the site, which is good for the ergonomic and comfortability aspects.

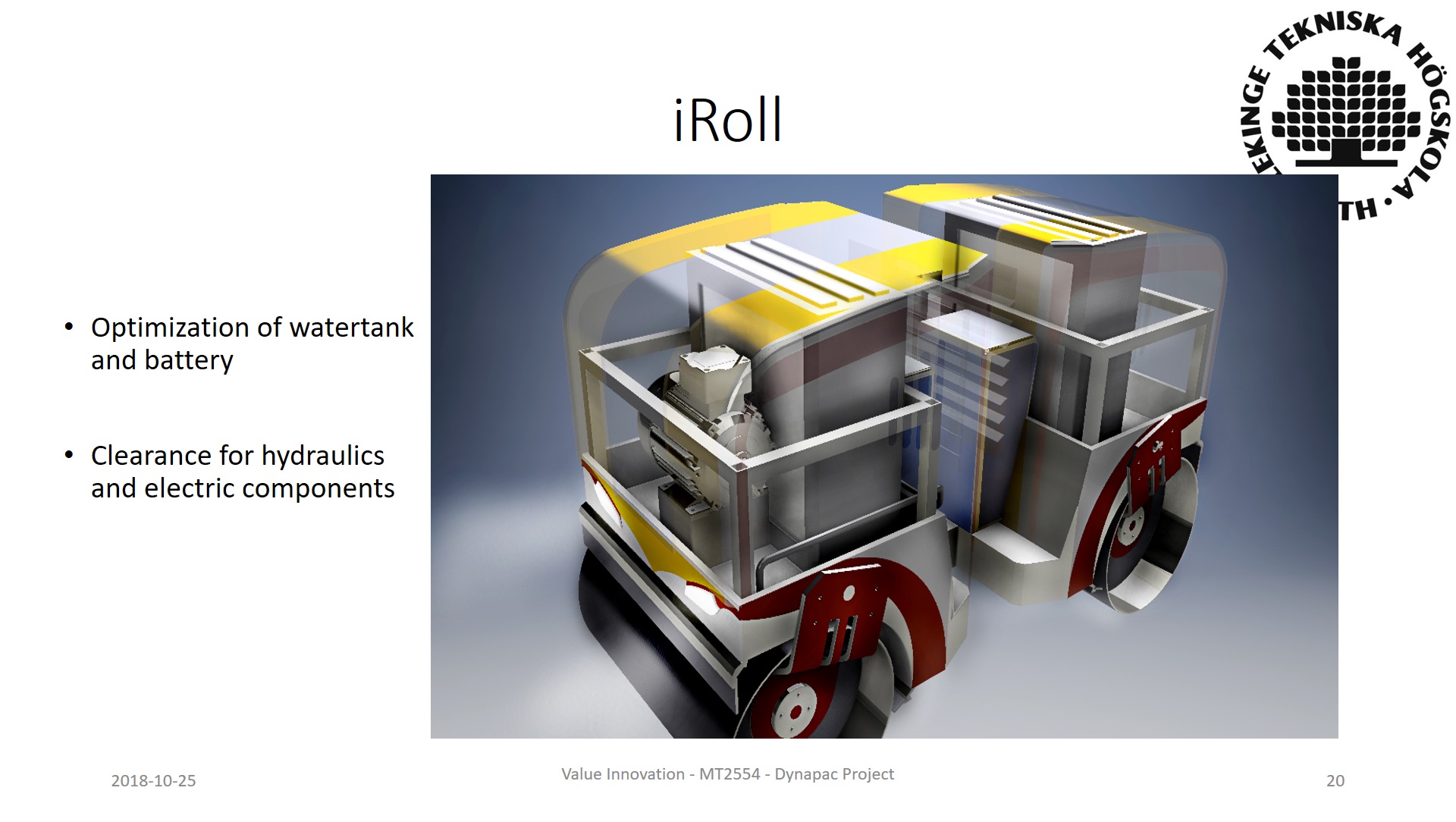

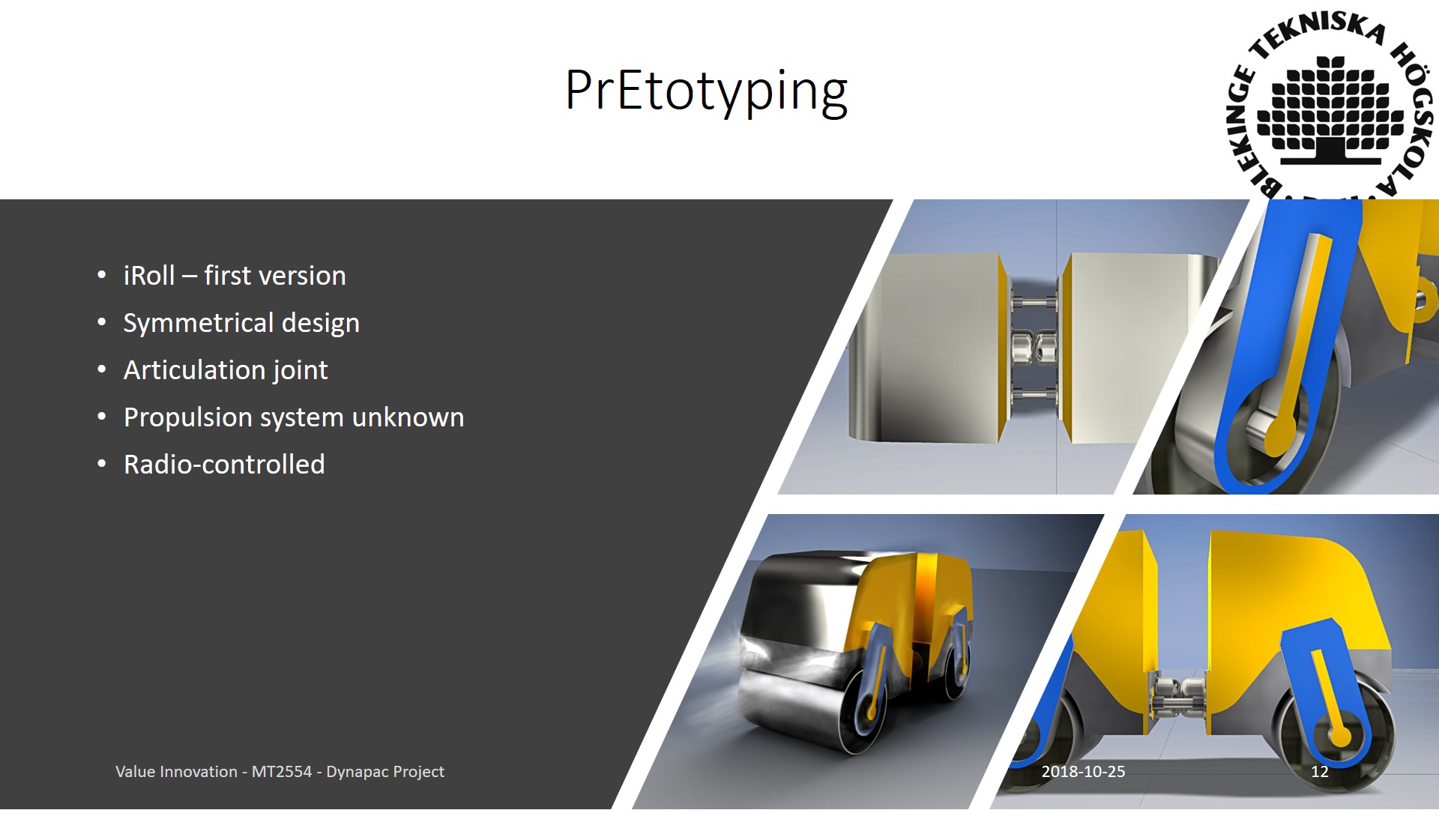

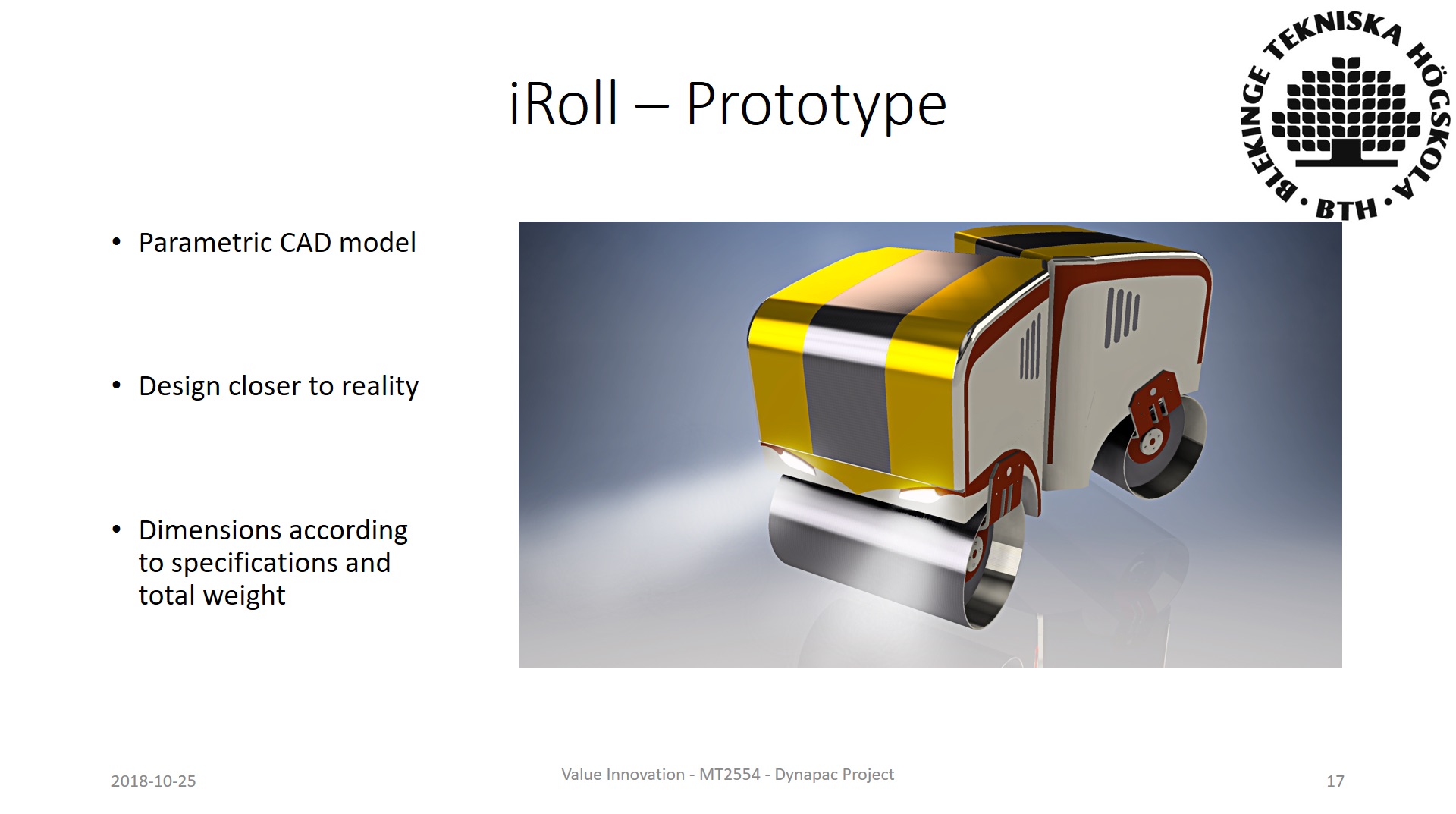

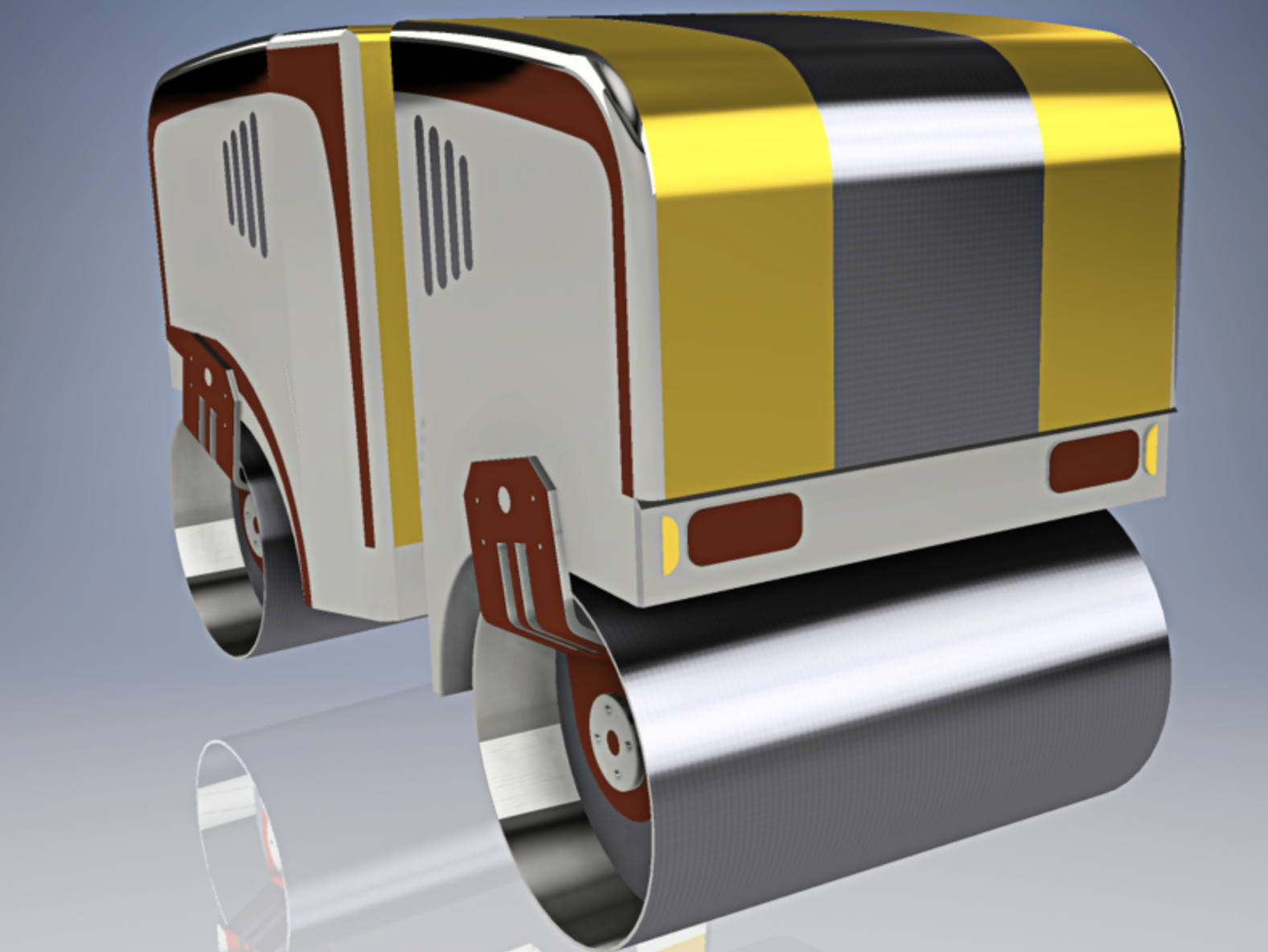

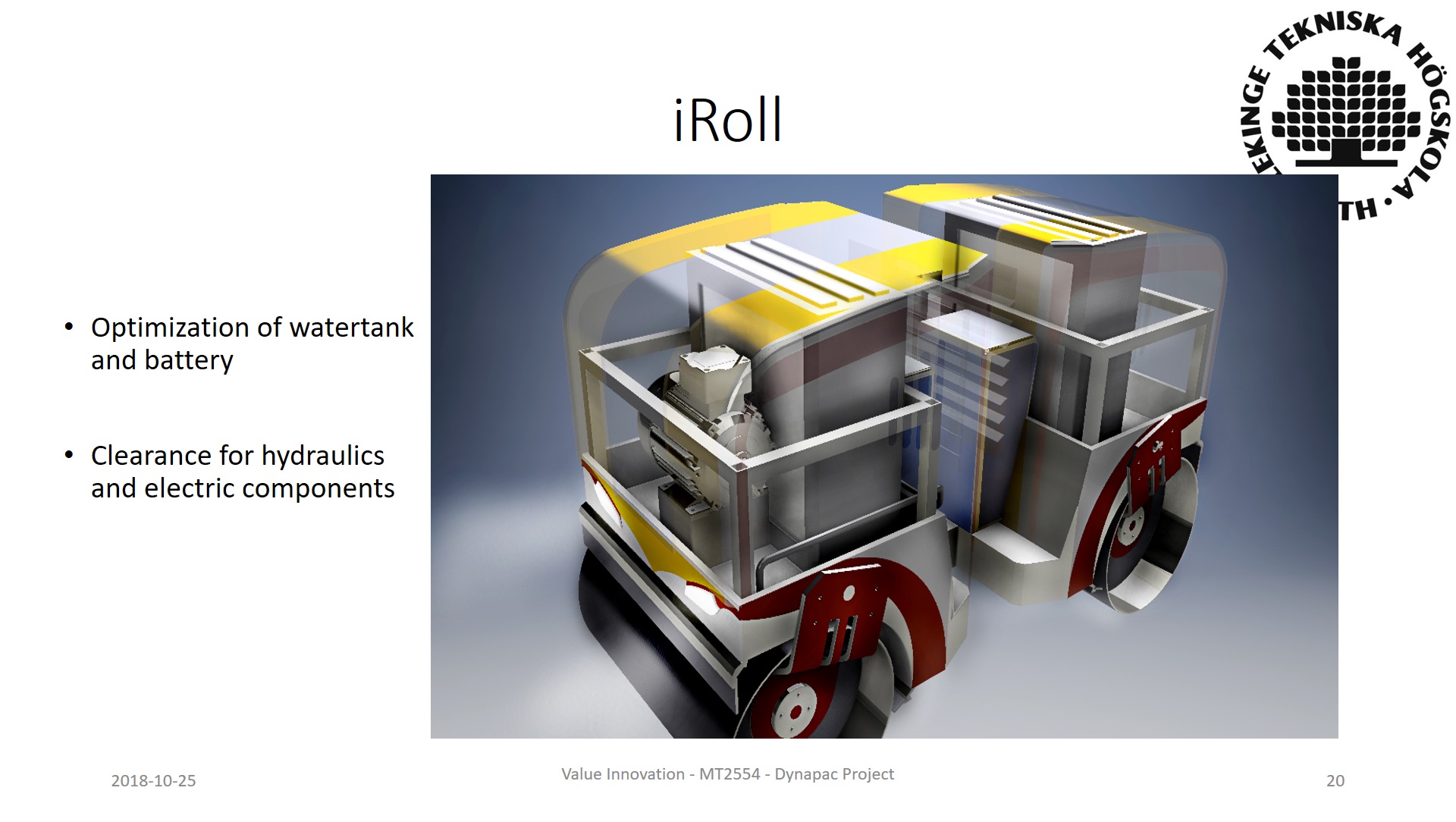

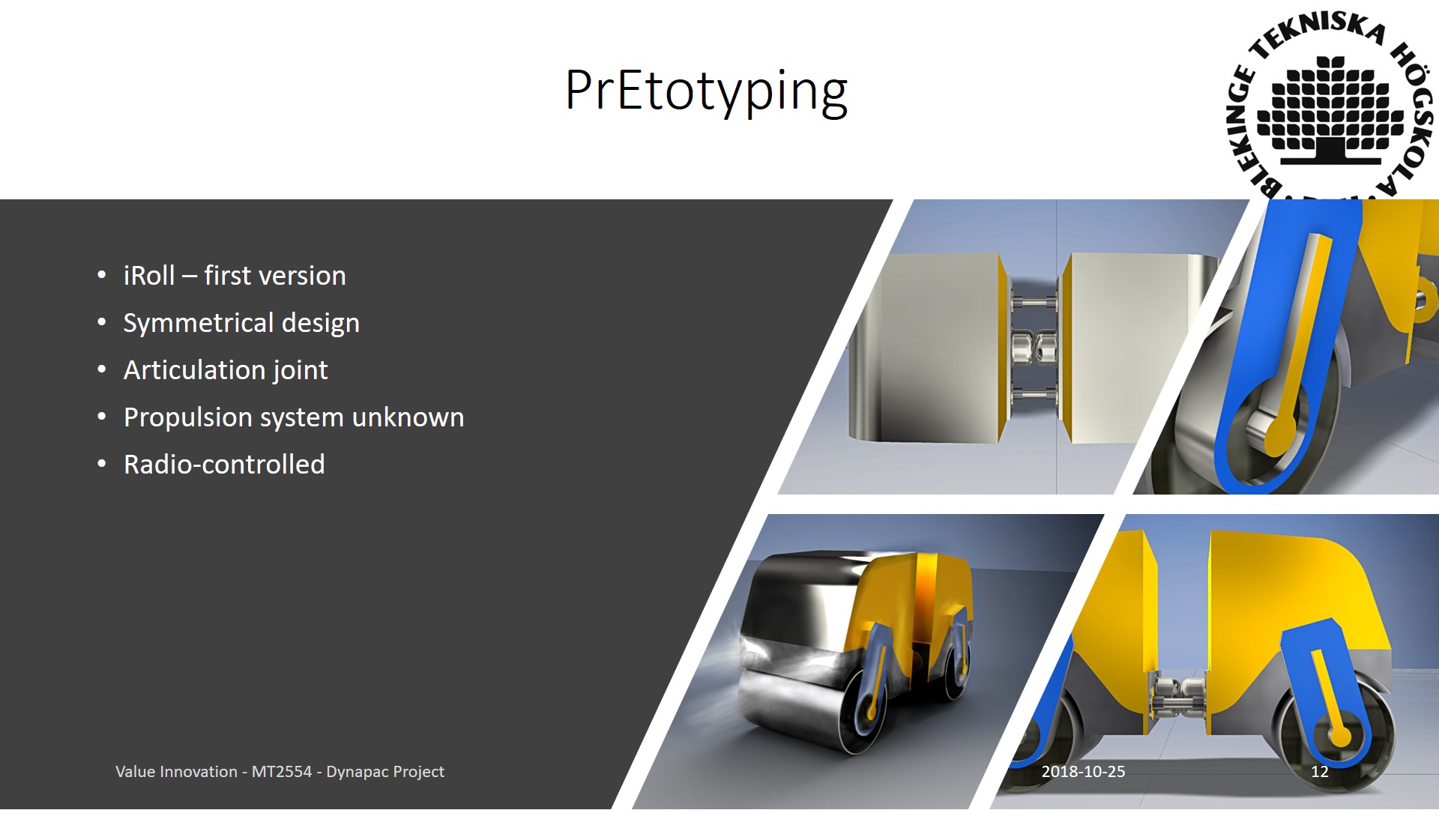

Prototypes: The prototype made was a 3D model in Inventor, where exact volumes and dimensions of the motor, battery and the watertank was implemented. The drums, and external dimensions was also identical with the current product. The purpose of the prototype was to see where the different components could be places, and how much clearance we had left for other components that have not been included into the design (e,g. additional electric components and hydraulics).

Quotes from sponsor/partner: –

Project team: Mattias Ghanem, Mojtaba Fayazi, Dastan Gomli, Abrahim Abdulkarim. All Msc. in Mechanical Engineering with orientation of product development in the 5th year at BTH.