Congratulations Wu Peng, Licentiate in Mechanical Engineering!

- Post by: Tobias Larsson

- 29th April 2025

- No Comment

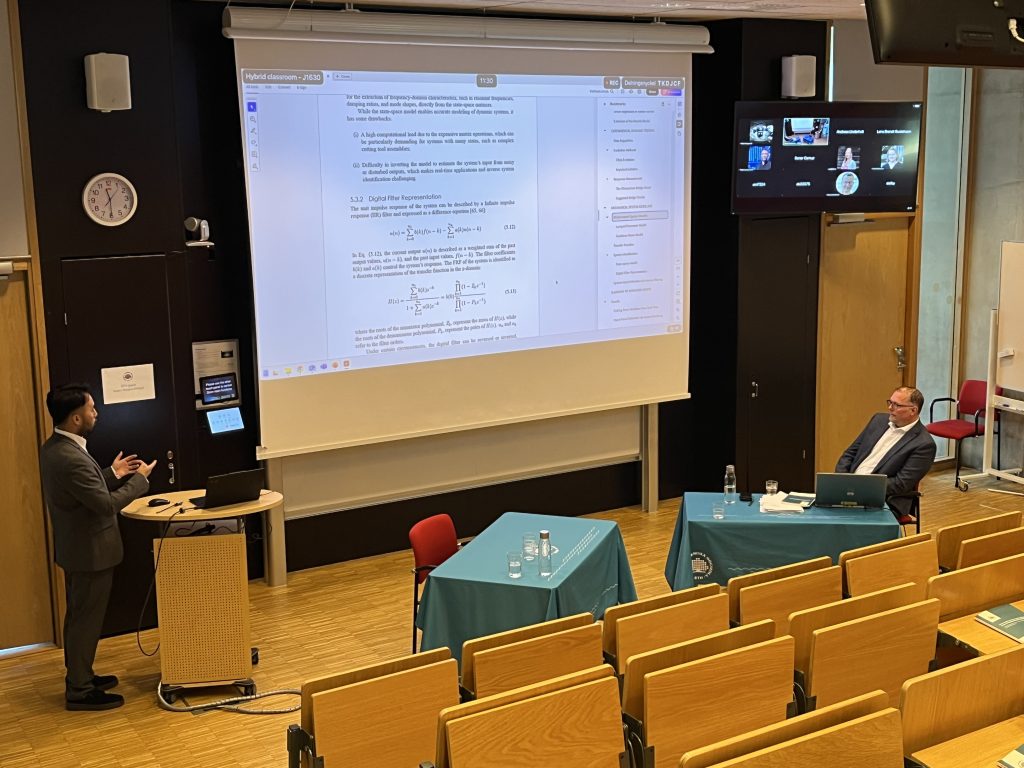

Wu Peng presented his licentiate thesis entitled “Enhanced Measurement and Prediction in Sensor-Equipped Metal Cutting Tools: A Model Based Approach for Force Estimation and Tool Wear Monitoring” in front of a crowd of local audience and online listeners.

Wu made a clear and applied presentation of the background and findings of his research, focusing on improving the measurement and prediction capabilities of sensor-equipped metal cutting tools. His work addressed how dynamic tool behavior affects sensor data, leading to new methods for force estimation and tool wear monitoring. The thesis consists of a summary part and three individual research publications, culminating in a model-based approach validated through simulations and experiments. Wu Peng conducted his research within applied projects at Blekinge Institute of Technology (BTH) and Sandvik Coromant, where he was also employed as an industrial PhD candidate.

The opponent for the day was Associate Professor Andreas Linderholt from Linnaeus University. With his strong background in mechanical engineering and industrial applications, Andreas served as an excellent opponent, critically examining the applicability of the proposed framework from Wu Peng and ensuring clarity around the research choices made. The discussion developed into a valuable reflection session for both Wu Peng and the audience.

At the end also the audience had the chance to ask questions on the research.

Examiner Professor Tobias Larsson then concluded by declaring that Wu had passed the exam and achieved the licentiate degree. The event was rounded up with classic swedish fika!

Thesis abstract

Sensor-equipped cutting tools enhance metal machining by allowing real-time monitoring of cutting forces, tool deflection, vibrations, and tool condition, improving process control and tool life. However, challenges such as noise, transfer path distortion, and inaccurate force estimation due to tool wear limit current solutions. This research integrates cutting force models, signal processing, and system identification to enhance measurement accuracy, prediction capabilities, and real-time monitoring for machining optimization.

This thesis establishes a framework to enhance the performance and reliability of sensor-equipped cutting tools by addressing how tool dynamics affect sensor data. Improving measurement quality improves the predictive capabilities of these tools, making them adaptable to various cutting tool configurations and applications.

A key contribution is an extended Kienzle-Sağlam force model that incorporates tool wear effects, enabling precise cutting force predictions and real-time tool wear monitoring. Additionally, an analytical approach for modeling strain-force transfer functions in metal cutting tools, combined with inverse filtering, corrects signal distortions in dynamic load estimations caused by tool dynamics. The developed methods can be used to improve the accuracy when estimating dynamic loads and tool-tip deflection, addressing limitations of statically calibrated systems.

This thesis presents a model-based method that accurately estimates dynamic loads and displacements in sensor-equipped cutting tools using strain response data. Validated through simulations and experiments, this method provides a foundation for continuing research aimed at adapting it for real-world applications, supporting the in-process monitoring of tool condition, machining stability, and surface quality.

Keywords: Sensor-embedded cutting tools, Cutting process modeling, Signal processing, Dynamic load estimation, Experimental dynamic testing

Thesis link: https://urn.kb.se/resolve?urn=urn:nbn:se:bth-27624