Minimizing the negative effects of coolant channels on the torsional and torsional-axial stiffness of drills

- Post by: Tobias Larsson

- 11th October 2021

- No Comment

Abstract

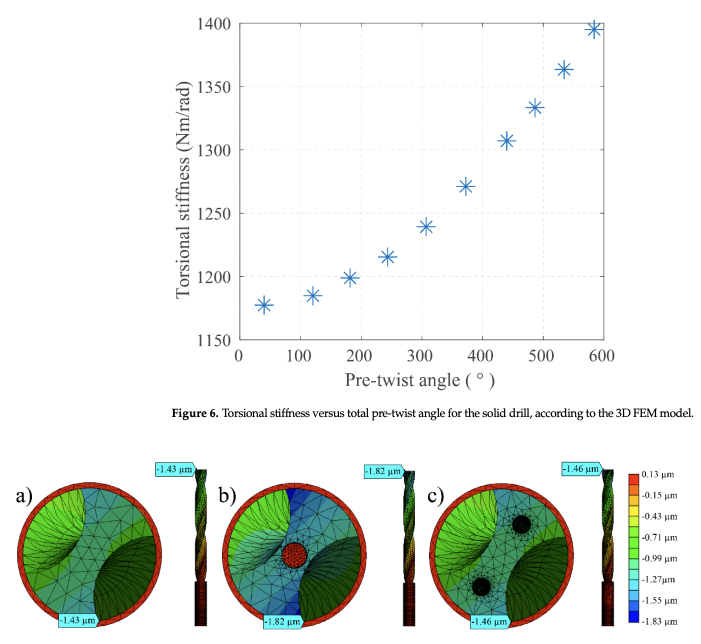

Coolant channels allow internal coolant delivery to the cutting region and significantly improve drilling, but these channels also reduce the torsional and torsional-axial stiffness of the drills. Such a reduction in stiffness can degrade the quality of the drilled holes. The evacuation of cutting chips and the delivery of the cutting fluid put strict geometrical restrictions on the cross-section design of the drill. This necessitates careful selection and optimization of features such as the geometry of the coolant channels. This paper presents a new method that uses Prandtl’s stress function to predict the torsional and torsional-axial stiffness values. Using this method drills with one central channel are compared to those with two eccentric coolant channels, which shows that with the same cross-section area, the reduction of axial and torsional-axial stiffness is notably smaller for the design with two eccentric channels compared to a single central channel. The stress function method is further used to select the appropriate location of the eccentric coolant channels to minimize the loss of torsional and torsional-axial stiffness. These results are verified by compari-son to the results of three-dimensional finite element analyses.

Keywords

Drilling, Dynamics, Stress function, Torsional stiffness, Torsional-axial stiffness

Citation

Parsian, A.; Eynian, M.; Magnevall, M.; Beno, T. Minimizing the Negative Effects of Coolant Channels on the Torsional and Torsional-Axial Stiffness of Drills. Metals 2021, 11, 1473. https://doi.org/10.3390/met11091473