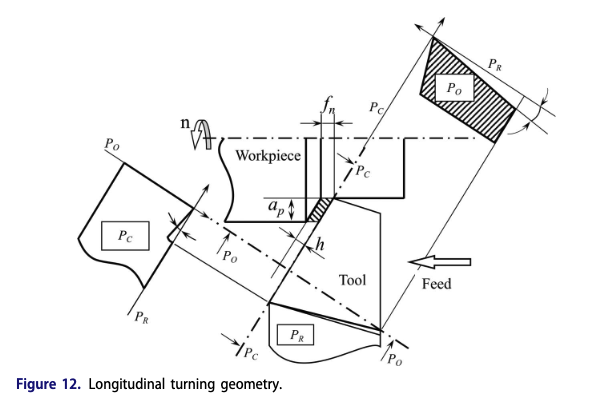

Abstract This study addresses the challenge of modeling flank wear impact on cutting forces in metal cutting. Accurate models are crucial for simulating the cutting process, optimizing insert geometry and […]

Read More

Abstract This study addresses the challenge of modeling flank wear impact on cutting forces in metal cutting. Accurate models are crucial for simulating the cutting process, optimizing insert geometry and […]

Read More

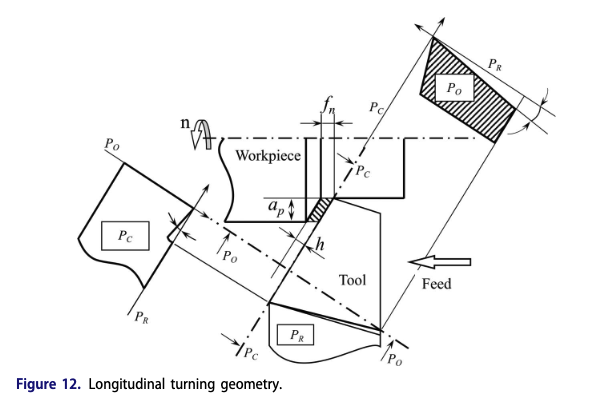

Abstract Manufacturing companies undergo a transformative journey in digital servitization, neces-sitating strategic, tactical, and operational shifts. The existing literature outlines the best prac-tices on this process and examines challenges and […]

Read More

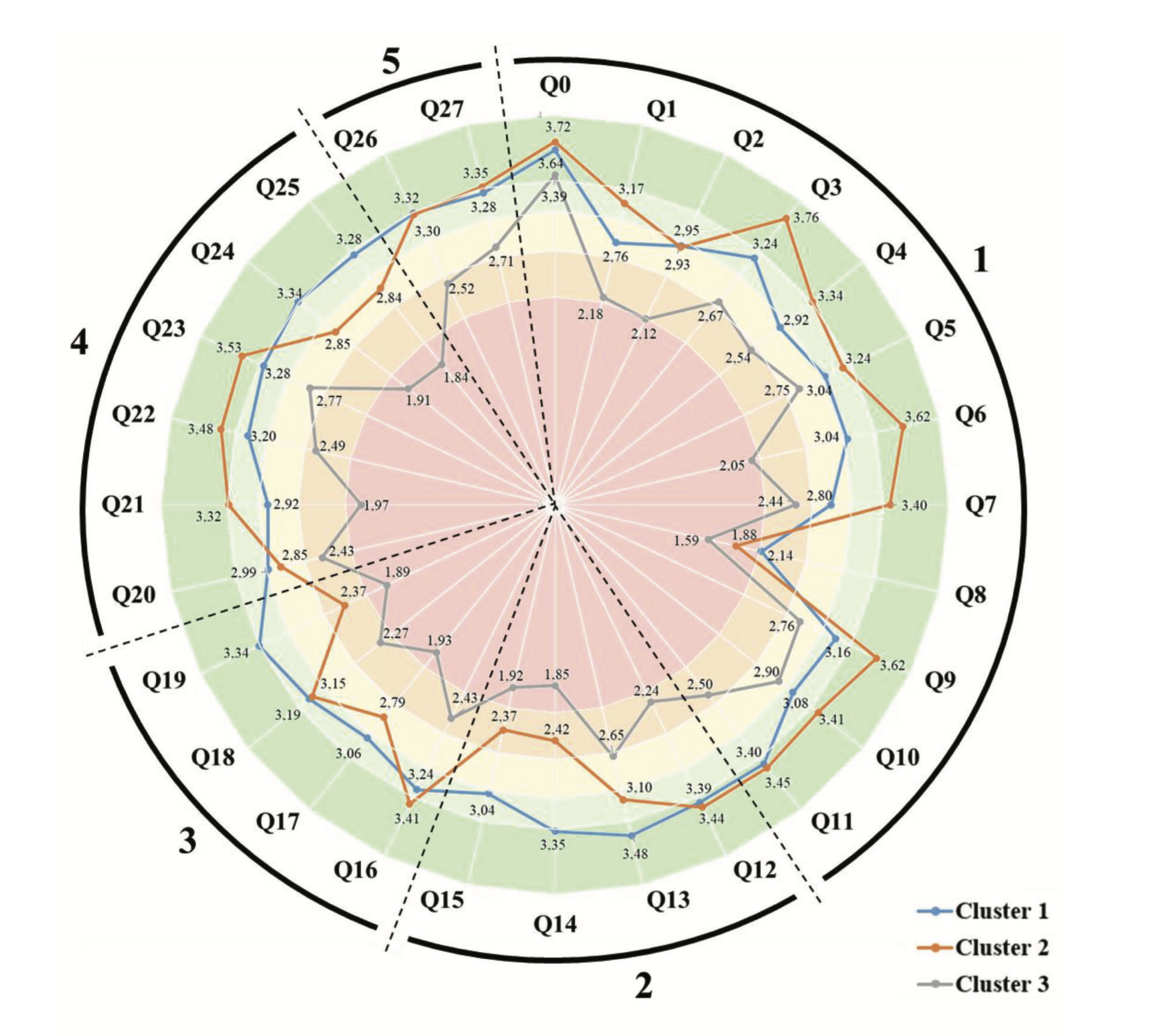

Abstract This work presents four sets of welded multi-wires on Cu sheet (e.g., A-(95/95mm2), B-(35, 35, 25/35, 35, 25 mm2), C-(50, 35, 10/50, 35, 10 mm2), D-(35, 35, 25/50, 35, […]

Read More

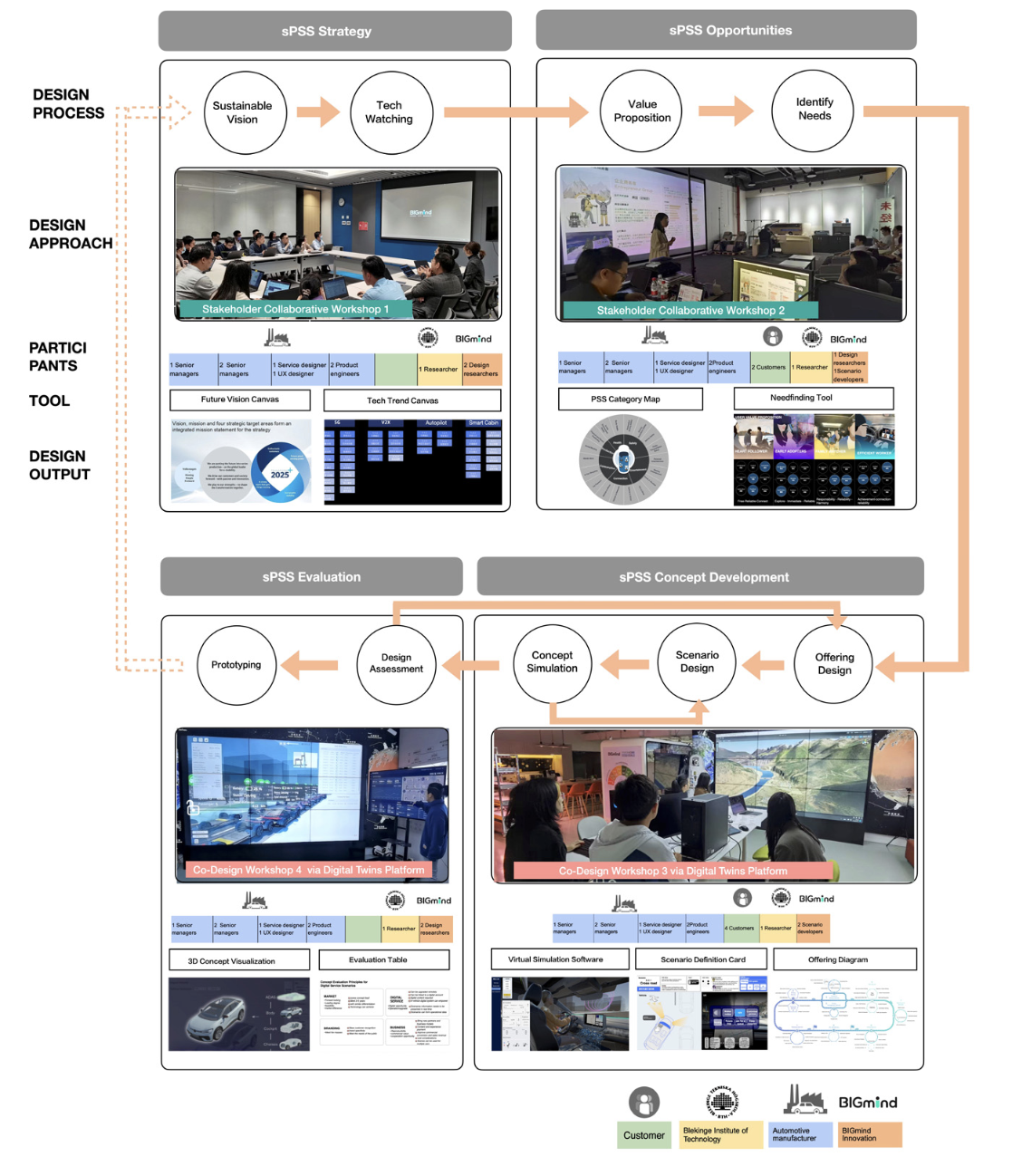

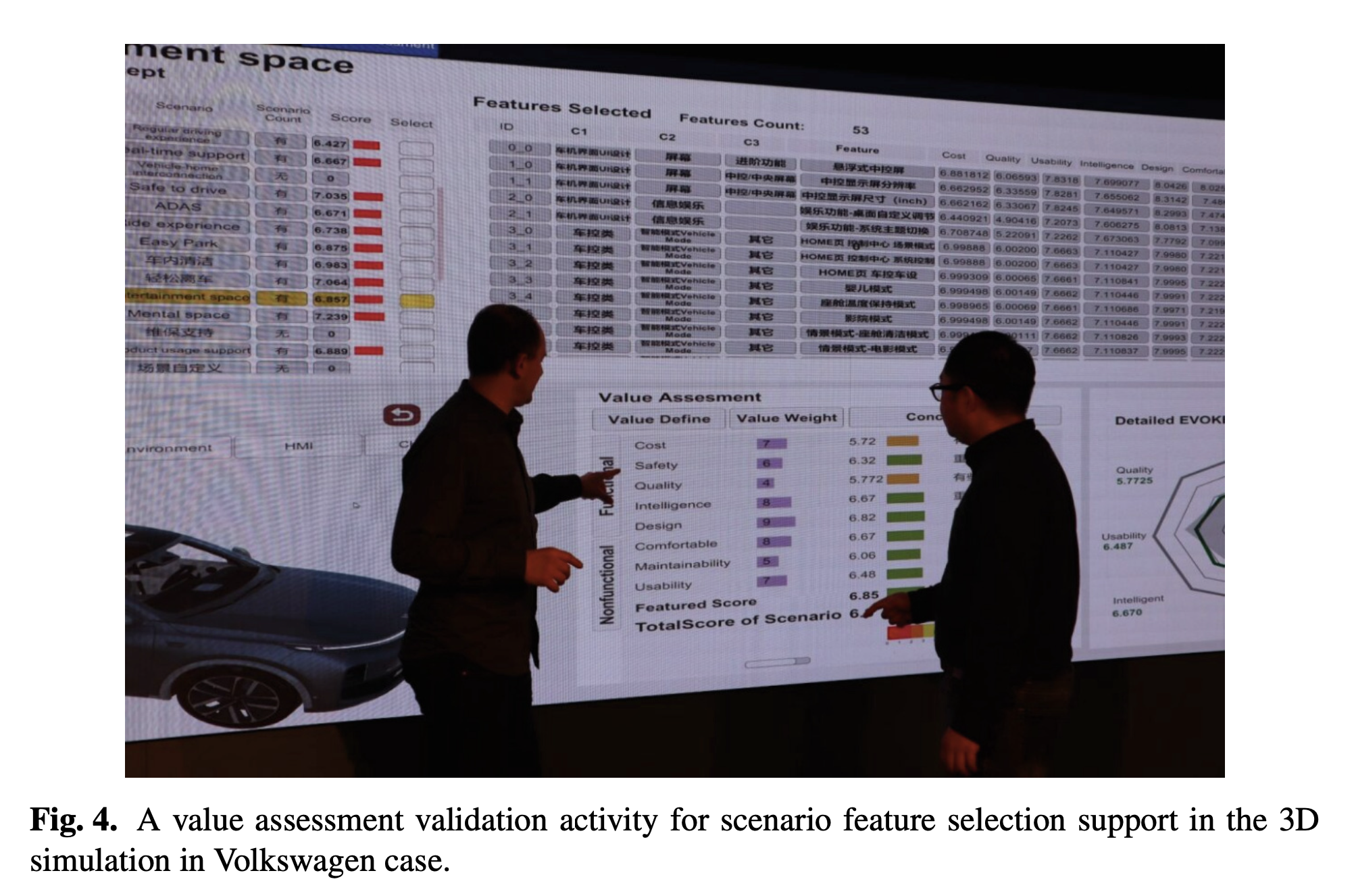

Abstract The Product-Service Systems (PSS) methodology faces new challenges as digital servitisation drives product-oriented companies to integrate digital services into their offerings. A value co-creation strategy and global collaborative innovation […]

Read More

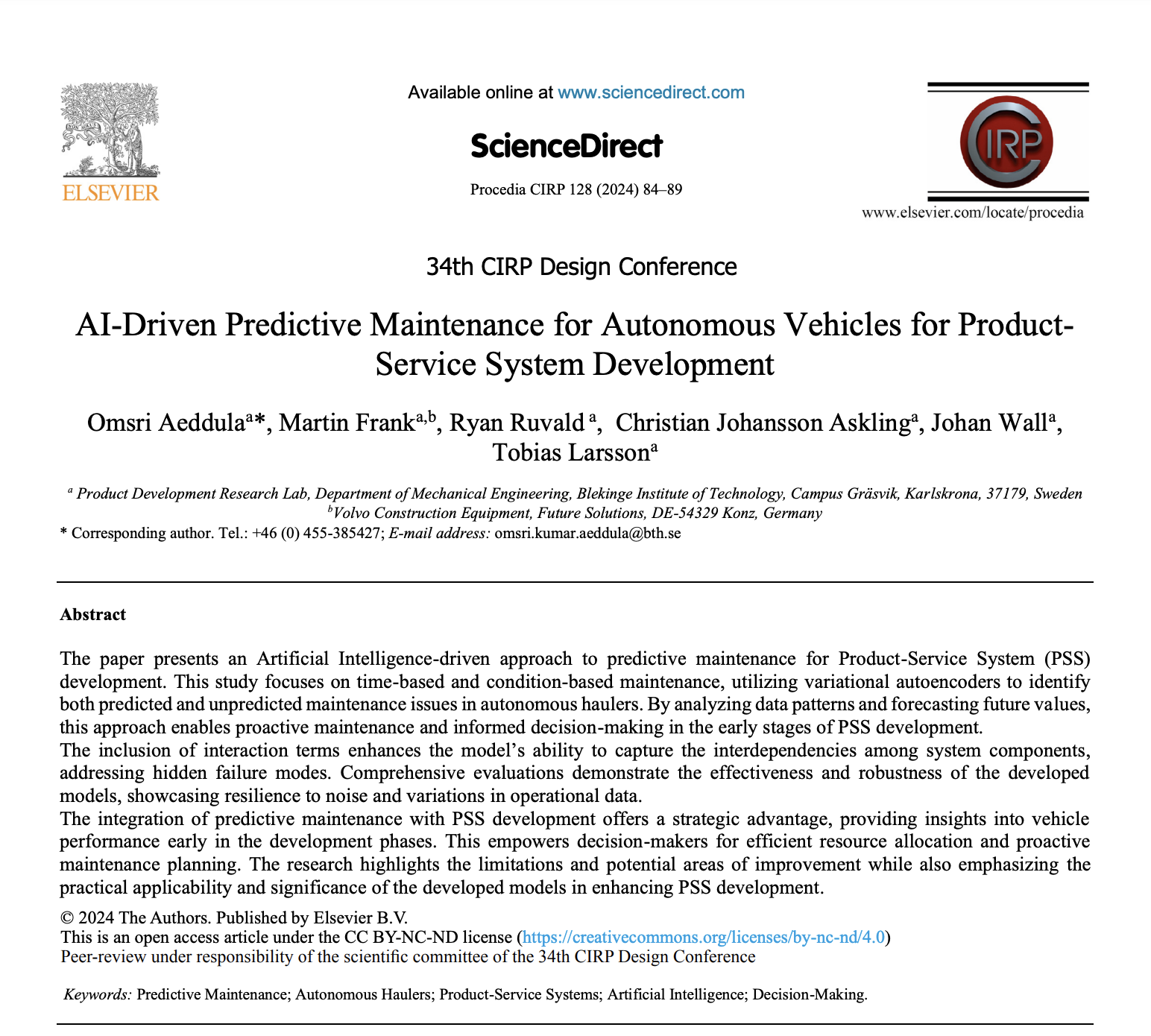

Abstract The paper presents an Artificial Intelligence-driven approach to predictive maintenance for Product-Service System (PSS) development. This study focuses on time-based and condition-based maintenance, utilizing variational autoencoders to identify both […]

Read More

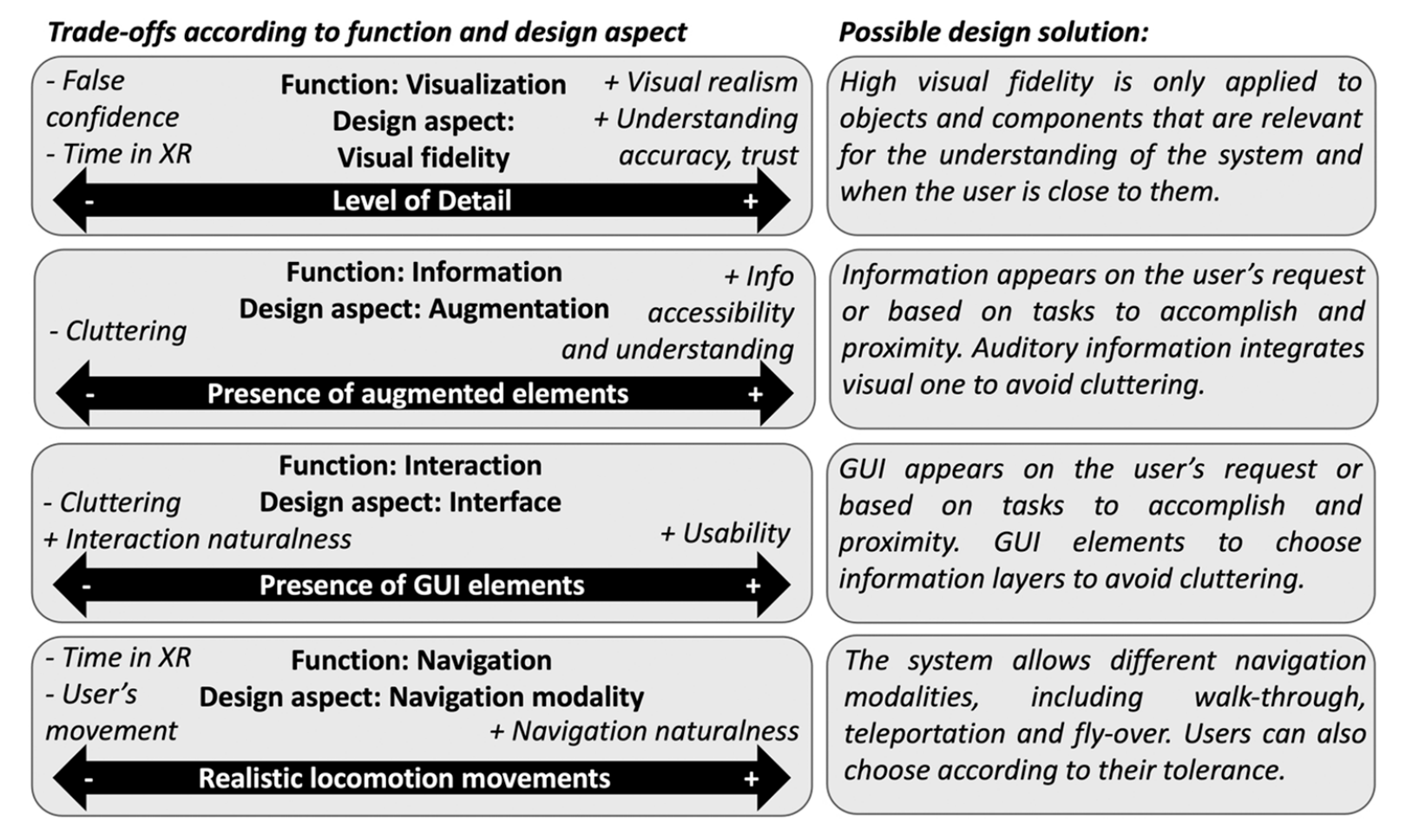

Abstract Extended Reality (XR) technologies are increasingly popular to support the engagement of different audiences and stakeholders with Discrete Event Simulations (DES) due to their capability to deliver more accessible […]

Read More

Abstract Manufacturing companies are increasingly transitioning from a product-centric to a smart Product Service System (smart PSS) approach to enhance customer satisfaction, service offerings, and product competitiveness through a combination […]

Read More

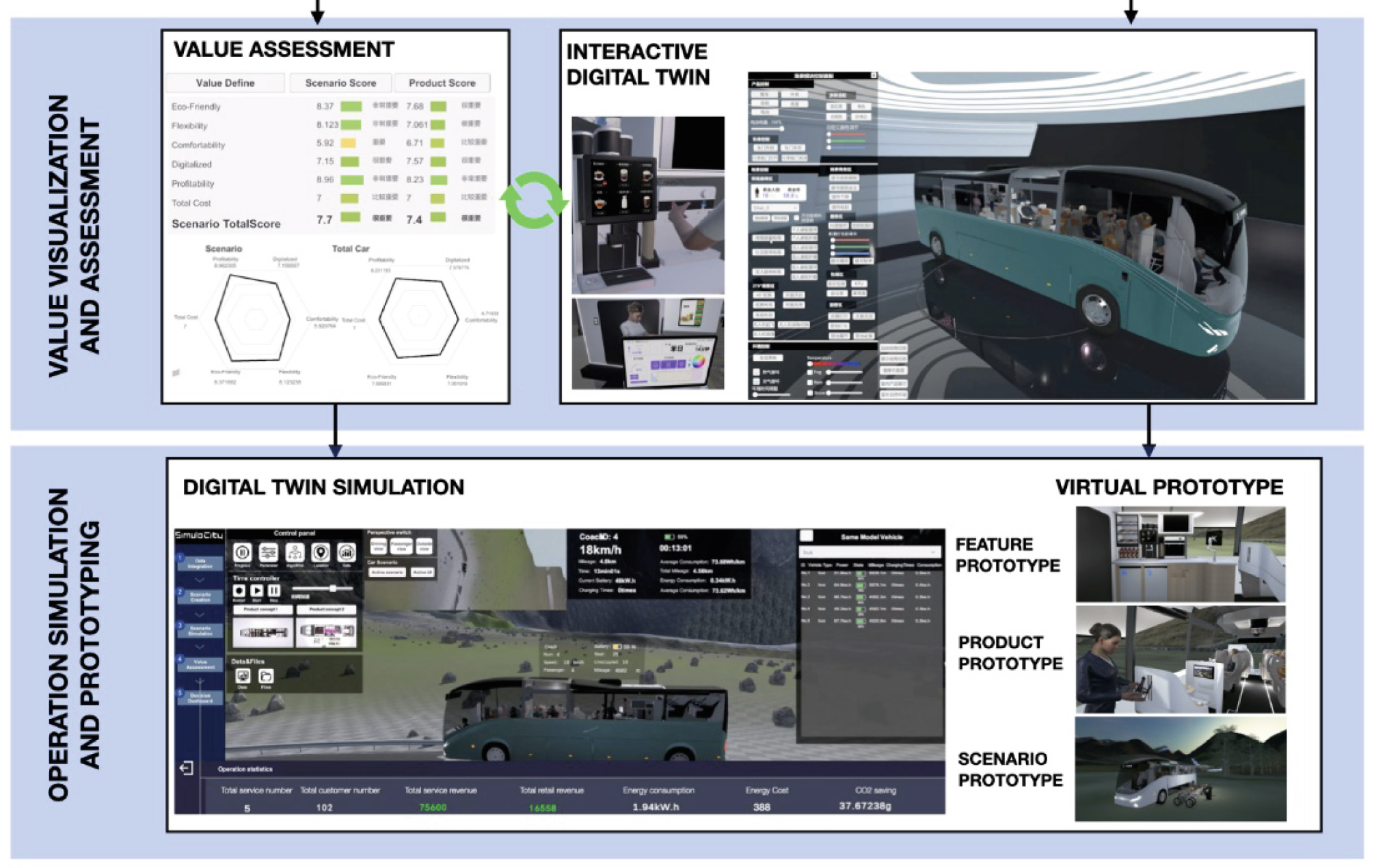

Abstract When bus manufacturing companies move forward in their servitization journey for providing service solutions for tourism industry, there is an increasing need to exploit the prototype way to support […]

Read More

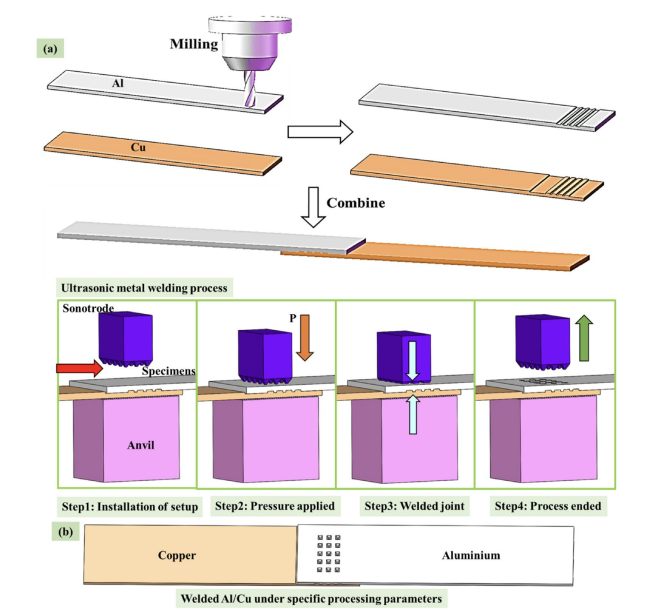

Abstract In this paper, dissimilar aluminum (Al) and copper (Cu) metals were joined together using ultrasonic metal welding (USMW), a solid-state welding technology. From the perspective of increasing the base […]

Read More

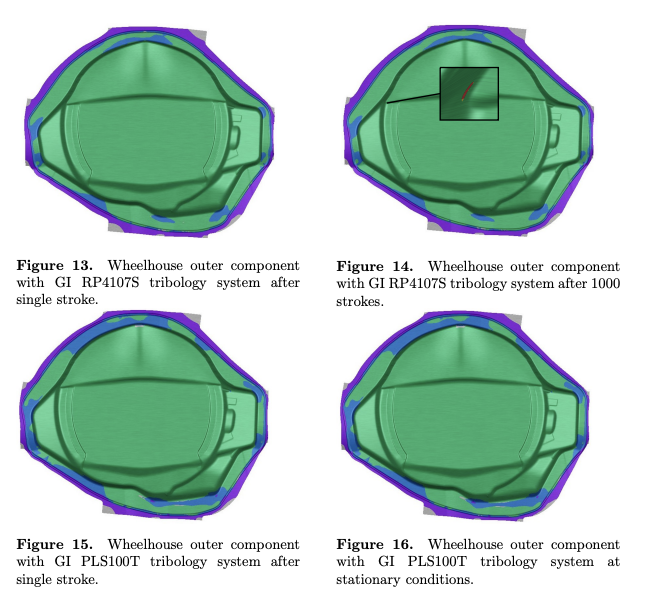

Abstract During the running production of automotive body components drifts in theprocess window is seen causing problems with non-conforming parts. Up until now, these driftshave been counter-acted based on the […]

Read More