Study of Shear Dominant Delamination in Thin Brittle-High Ductile Interface

- Post by: Tobias Larsson

- 6th September 2016

- No Comment

ABSTRACT

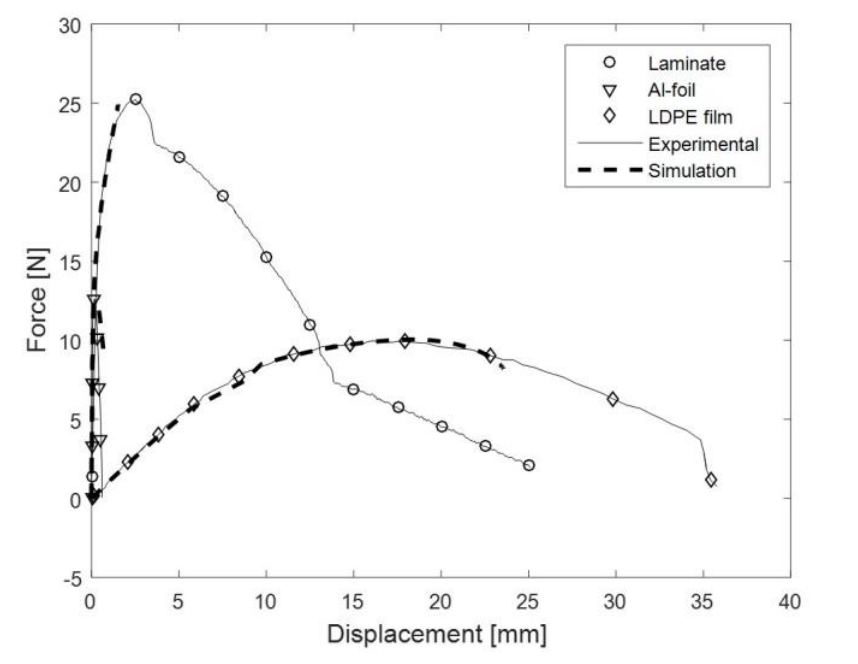

Thin laminates of Aluminum (Al) foil and Low Density Polyethylene (LDPE) film are essential constituents of food packages where these two substrates are bonded together with a thin layer of LDPE acting as adhesive. Noticeably, Al is a low ductile/quasi brittle material, whereas LDPE is highly ductile. The mechanism of delamination and strength of bond between the interfaces dictates the continuum and damage behavior of this composite. However, measuring the shear delamination properties is challenging as conventional test methods have limitations when the substrates are very thin and flexible. This study explains a tentative method that uses uniaxial tensile testing on the pre-cracked specimen of this composite to find energy dissipation due to shear delamination and successfully uses it in Finite Element Simulation in Abaqus. The delamination was observed in a narrow strip-like region close to fracture surfaces and measured with special visualization aid. A similar response was found in FEM simulation. Scanning Electron Microscopic (SEM) study of delaminated interface confirms the delamination to be shear in nature. In a cohesive zone modeling in Abaqus, the measured shear delamination energy was used as input parameter along with an arbitrary bi-linear cohesive law for validation of the experimental measurement.

KEYWORDS

Interlaminar shear delamination, thin flexible substrate, composite, cohesive zone modeling, work of fracture, tensile testing

CITATION

Elsevier, 2016. Vol. 2, 152-157 p. DOI: 10.1016/j.prostr.2016.06.020

DOWNLOAD

http://urn.kb.se/resolve?urn=urn:nbn:se:bth-12996