A prediction of cutting forces using extended Kienzle-Saglam force model incorporating tool flank wear progression

- Post by: Tobias Larsson

- 18th March 2025

- No Comment

Abstract

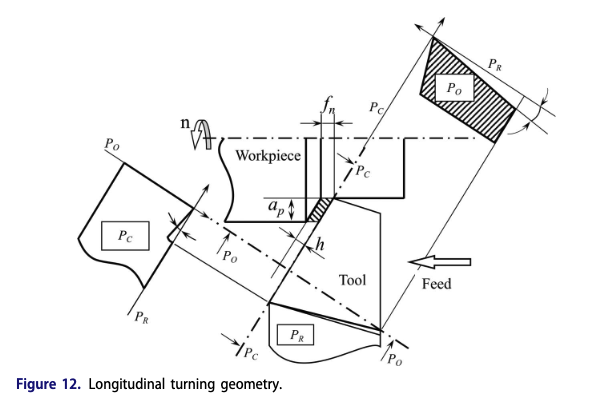

This study addresses the challenge of modeling flank wear impact on cutting forces in metal cutting. Accurate models are crucial for simulating the cutting process, optimizing insert geometry and monitoring machine tools. The objective is to develop an extended Kienzle-Sağlam force model that considers tool rake angle, uncut chip thickness and tool flank wear. Experimental tests involve orthogonal turning with coated inserts, cutting force measurements with a dynamometer and flank wear progression monitored using an optical measuring robot. By integrating measured cutting forces and flank wear progression, the study extends the mechanistic cutting force model, with flank wear as an input parameter. The proposed model is validated against force measurements, using commercial cutting tools in longitudinal turning conditions. The findings of this study suggest that the developed cutting force model effectively captures the effects of the considered input parameters and accounts for different stages of tool wear. The results also show that the tool flank wear significantly affects the radial and feed force components, which is an important finding potentially affecting the prediction capabilities in future generations of sensor-embedded cutting tools, aiming at tool life monitoring, prediction of tool deflection and cutting process stability.

Keywords

Cutting forces, extended Kienzle-Sağlam model, predicting cutting forces, regression model, tool flank wear

Reference

Peng Wu, Anders Liljerehn, Martin Magnevall & Dan Östling (25 Mar 2025): A prediction of cutting forces using extended Kienzle-Sağlam force model incorporating tool flank wear progression, Machining Science and Technology, DOI: 10.1080/10910344.2025.2473572