Professor Larsson blog

”Slow Productivity - The Lost Art of Accomplishment Without Burnout” caught my eyes as everything in society today is about tempo, pace and efficiency. Personally I think that is a broken view on productivity. Newport share the same view apparently this; “The knowledge sector emerged as a major force in the mid-twentieth century . . . the old notions of productivity that worked so well in farming and manufacturing didn’t seem to apply to this new style of cognitive work.” I also recognize that if I am seen in my office, or signs of productivity like email replies, chat messages…

Read more

Q & A with Professor Tobias Larsson

In this interview session, Professor Tobias Larsson, Dean of Faculty of Engineering, and Research Director in Mechanical Engineering, shares his perspectives on the difference between developing ‘function’ vs. ‘hardware‘ and reasons on the mechanical engineering research at BTH.

Q: What differentiates Product-Service Systems from the development of ‘traditional’ products, and what is your contribution to such processes?

A: Firstly; product-service systems (functional provision etc.) is coming into play because of a more circular economy thinking driven by sustainability desires. Use less resources to provide better solutions I would say, and this becomes an item of servitization, or providing access to solutions instead of selling goods.

The shift in business strategy from one-off sale to longterm commitments pushes companies to be closer to their customers and to be aware of the value creating activities. In the business-to-business domain, ‘traditional’ products are engineered to be sold as products and not as function providers. The traditional one-off sale used to make maintenance and after-market services a potential income. In the function perspective, the aftermarket activities might possibly be a cost for the provider.

Secondly; since the entire lifecycle of the product is important, the knowledge regarding product use is of key importance, and having this knowledge already in the design phase (through simulation and knowledge reuse) becomes a crucial advantage. Thirdly; the focus on function performance rather than product performance opens up the design space regarding what possible solutions exist. Our main contribution is to put life-cycle commitments in focus and, through research and design, tailor the development processes for products that are part of such commitments. An outlook shows that the entire sharing economy (with dematerialisation and service/function focus) is happening across several disciplines; AirBnB disrupts classic hotel business providing a (internet-enabled) layer where anyone can share their space. Uber is reshaping transportation in similar way. Internet of Things is sweeping across classic products, making everything connected.

In short, exciting times!

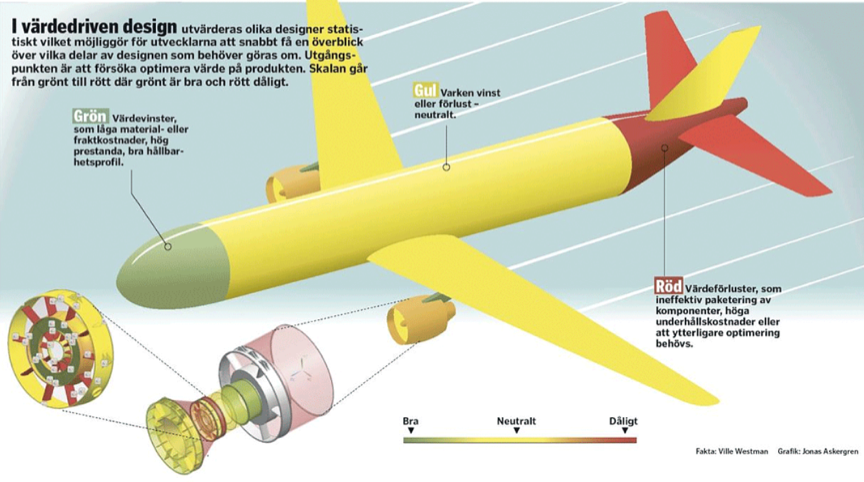

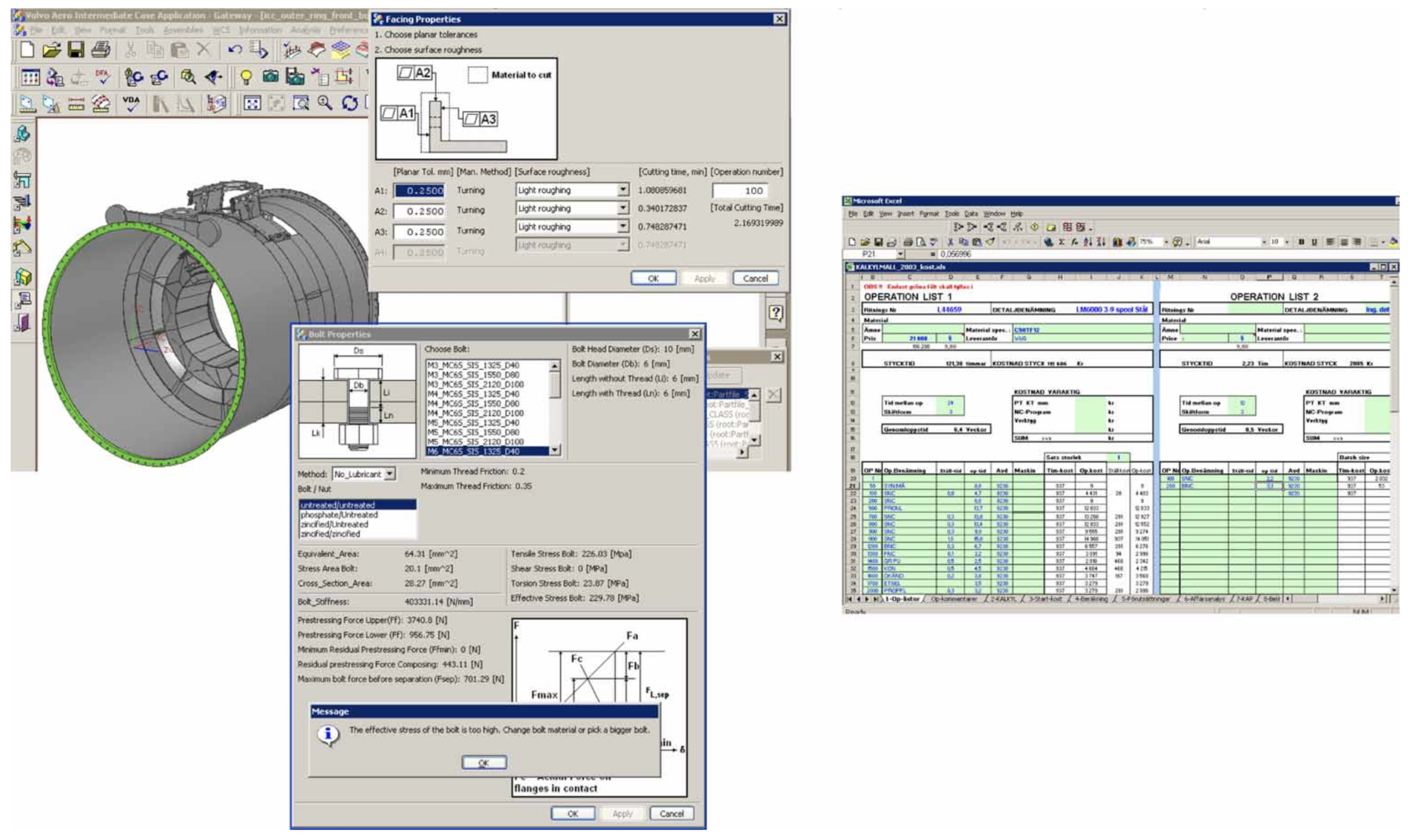

Sandberg, M., Boart, P., Larsson, T. (2005) Functional product life-cycle simulation model for cost estimation in conceptual design of jet engine components. Concurrent Engineering - Research and Applications, 13(4): 331-342 http://dx.doi.org/10.1177/1063293X05060136

Sandberg, M., Boart, P., Larsson, T. (2005) Functional product life-cycle simulation model for cost estimation in conceptual design of jet engine components. Concurrent Engineering – Research and Applications, 13(4): 331-342 http://dx.doi.org/10.1177/1063293X05060136

Q: How can you talk about Product-Service Systems and ‘total life-cycle commitments’, and at the same time focus so strongly on the early phases of engineering development?

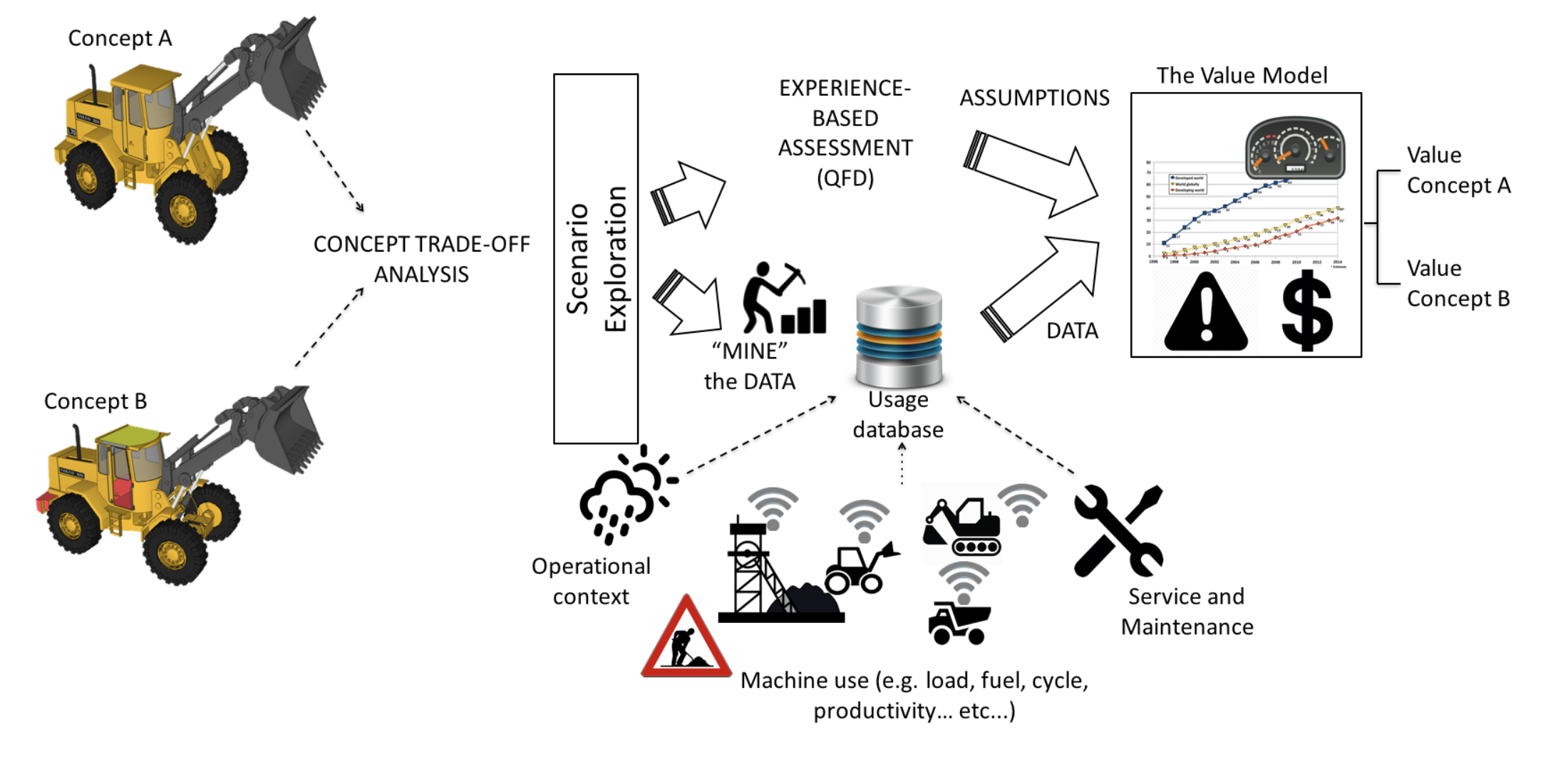

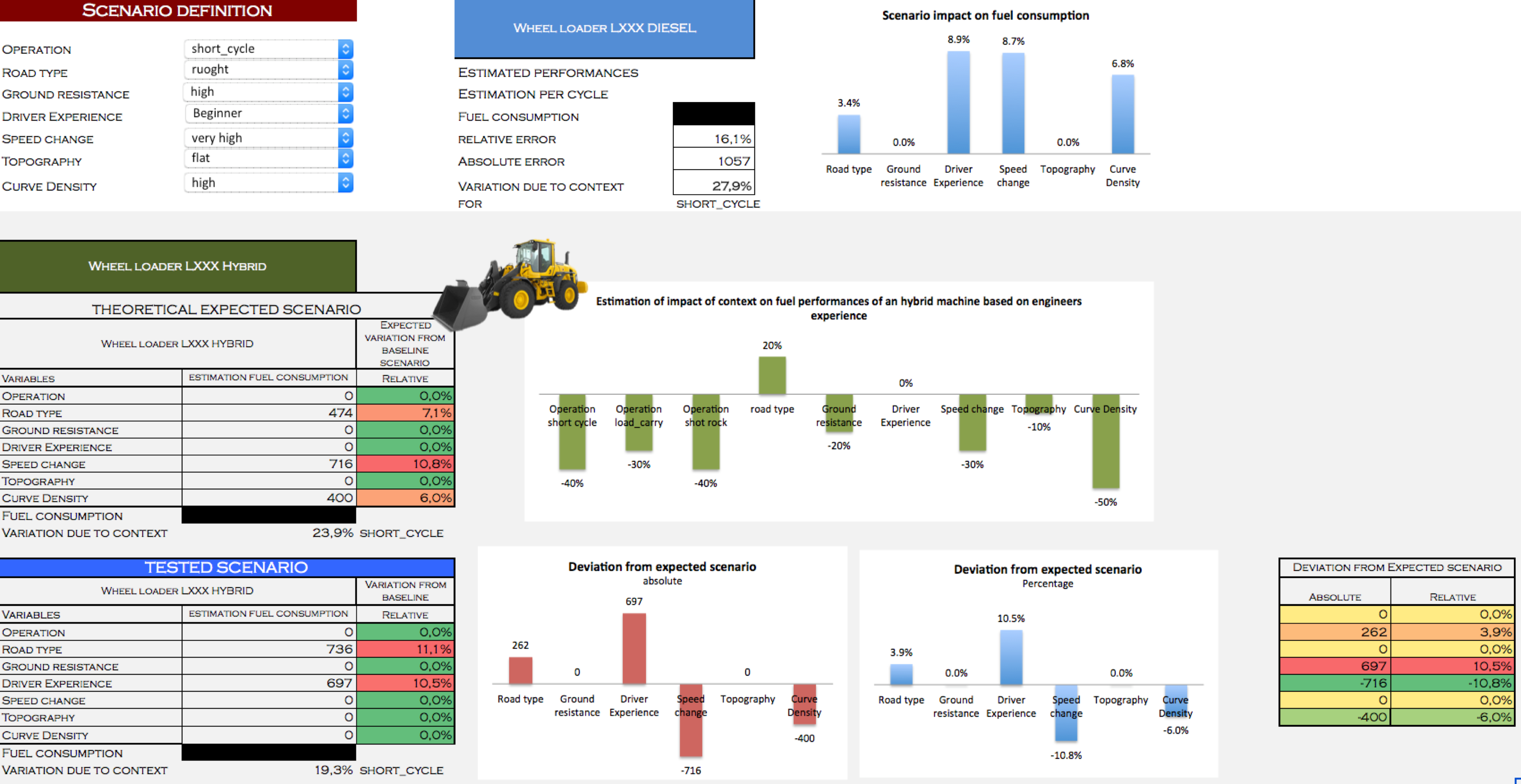

A: Make no mistake; this is a subject where modeling and simulation becomes more important than ever. The knowledge of product lifecycle usage, the reapplication of that knowledge, and the possibility to simulate function performance over life-cycle becomes key, especially in the early phases of design before making the investments in expensive hardware, or production. This is why we need to merge our expertise in Model Driven Development (Design Automation and Simulation Driven Design), Innovation Engineering (Value Driven Design etc,) with the overall skills in Product Development perspective to explore and develop knowledge intensive tools and methods for knowledge capture and reuse, for the purpose of predicting lifecycle effects of early decisions in the concept phase, arriving at a model driven decision environment (model based engineering) where final value is in focus. Hence, companies and customers want the innovation output of such a process, and our part is the early model based engineering approach to manage the complexity of balancing needs and requirements and design a desired outcome.

Our Decision Arena approach where models, analysis, visualisation of multiple domains come together on the 'Engineers Desktop' for better decisions is valuable here.

Q: You work in the intersection of business, engineering, and human values. What does the term ‘simulation’ include in such a highly diverse context?

A: Simulation entails representing certain key characteristics or behaviours of a selected physical or abstract system. The regular idea of simulation is that it is about representing the performance of products in terms of stress, strain, etc. Here, we use simulation to represent systems – early in the concept phase – as they might play out if particular decisions are made. Then it becomes possible to evaluate a wide range of possible decisions before actual development costs occur. By deploying a model based approach we quickly see the issue of simulating qualitative values like feelings for a solution etc and this drives our research to a higher level of fidelity. Some refer to this as digitalisation. I kind of see it as a “serious play" concept where you use simulation models to play out, and create, scenarios before they occur and make deliberate design decisions on this.

We touch upon business because cost/value are important factors in development, and human values are important since users/customers are always in the process, but having said that, we use this knowledge to engineer the solutions, and engineering product development is our 'home court'.

Bertoni, A., Larsson, T., Larsson, J. and Elfsberg, J., 2017. Mining data to design value: A demonstrator in early design. In ICED17, International Conference on Engineering Design

Q: You also promote a ‘knowledge based’ and ‘information driven’ approach. Why are aspects of knowledge and information so central?

A: Without going into definitions, it is about effectively utilising the information and knowledge that exists in processes, products and persons, so it can be acquired, evaluated, and used to make the ‘best’ possible decision in any given context and situation. If we know how a product is being used in the field, IoT technologies to bring that data to the table of design engineers together with qualitative data of perception (needs) it quickly becomes a game of knowing how to deal with large data flows and built-up experiences from users. Bringing that into executable models is a quest worth working on!

Q: In light of globalisation, what can your research center do to facilitate collaboration in development teams that are spread all over the world?

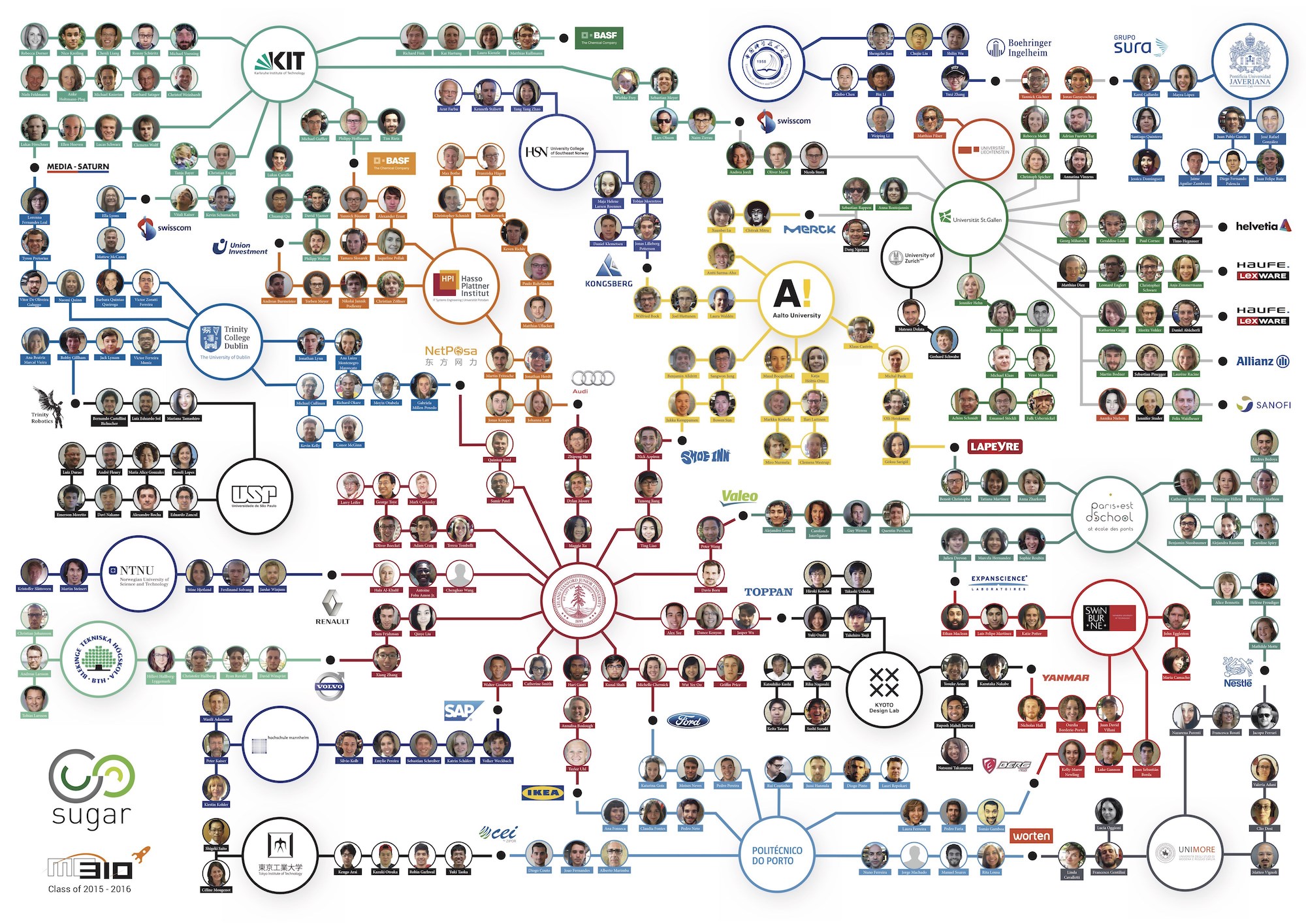

A: It is a fact that most businesses are spread across different geographical locations, different corporate cultures, etc. Our work on team innovation focuses on putting the development teams in focus and supporting them with tools, methods and best practices that aid their work process. Although not restricted to engineering, the engineering task is somewhat demanding in terms of collaboration due to the heavy demands engineers have on their work environment so here we find it extremely interesting to bring in new tools and methods that are better tailored to the task at hand. Supporting the creation of team culture and working with innovation assessment on team levels help these innovation teams to do some disruptive “damage" in their organisations for the benefit of better solutions.

Q: You have forged a very strong relationship with Stanford University. In which areas do you see them contributing the most to the Product-Service System Development field?

A: Stanford are at the forefront of Design Thinking in the world and we have mutual benefits of collaboration; they appreciate our exceptionally close industrial cooperation that gives us lead on being “close to the customer”, observing trends in industrial development. They also find our analytical simulation skills intriguing. They bring in a strong tradition of design studies and have lots of research experience related to design observatories. Their innovation drive and our systematic approach to knowledge sharing and product development provides an interesting mix that will benefit both parties in future research, education and industrial development. Some of us have worked together for 20 years and that grows on you. For the past 5 years we have run student projects with Stanford in the global ME310 program and that has gotten our education to another level also.

No matter the future is bright!