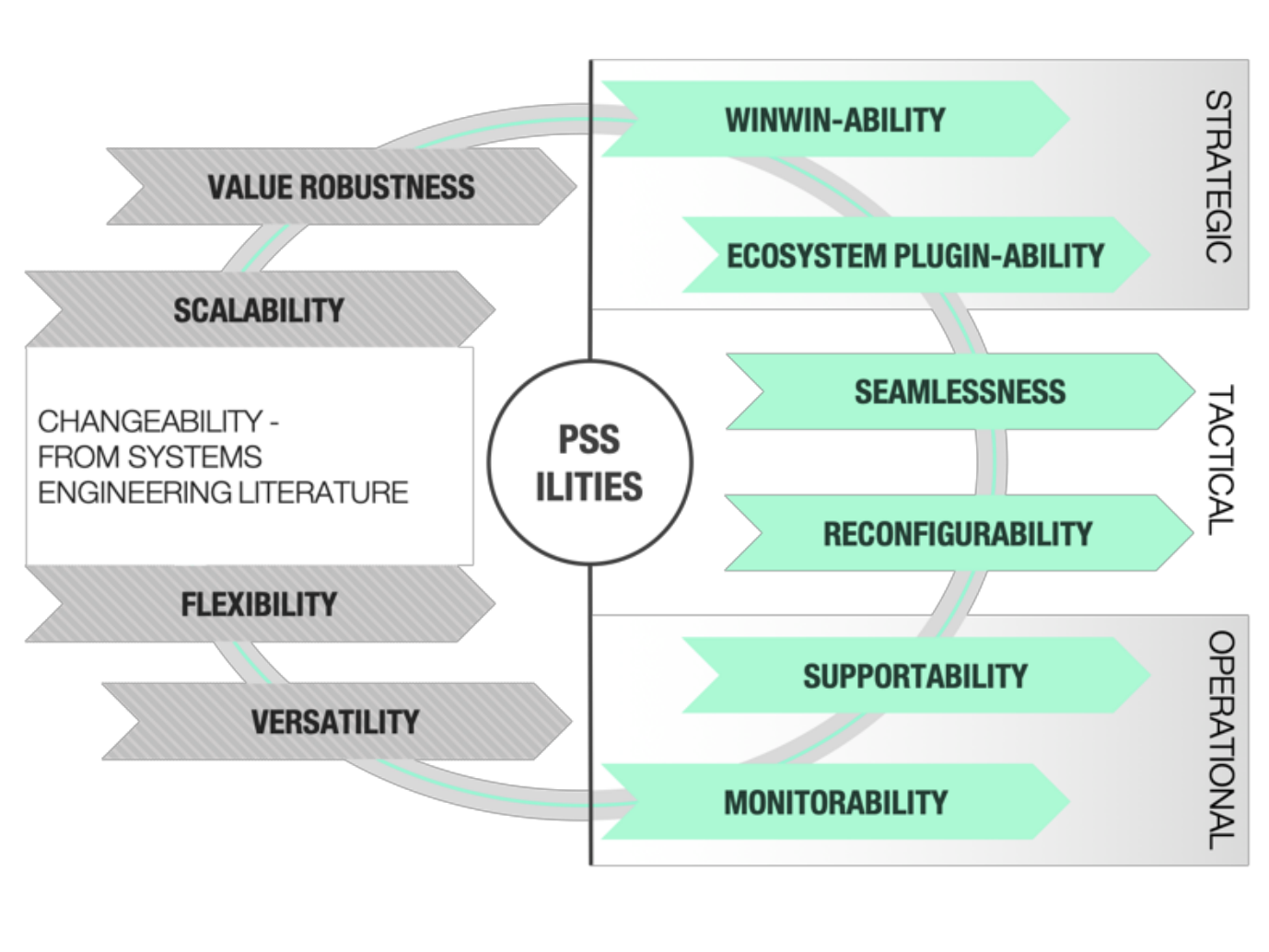

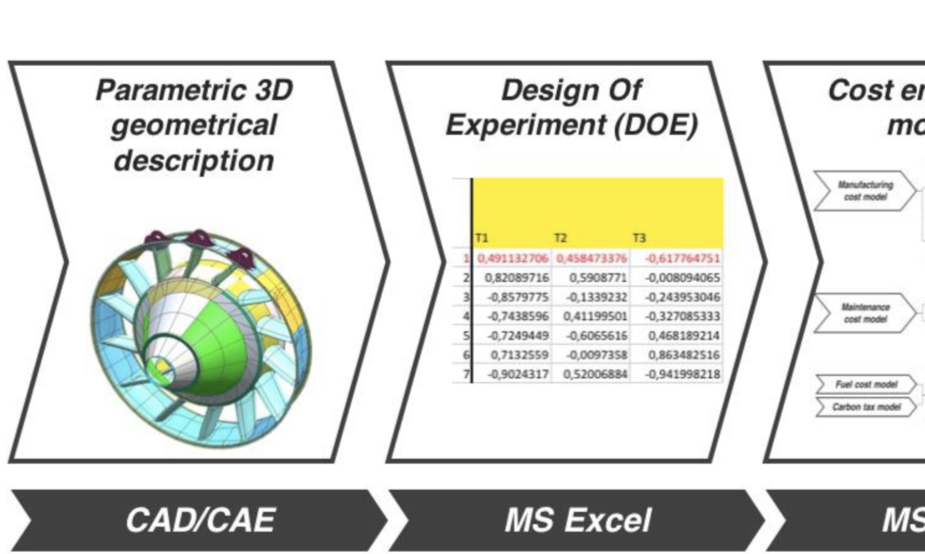

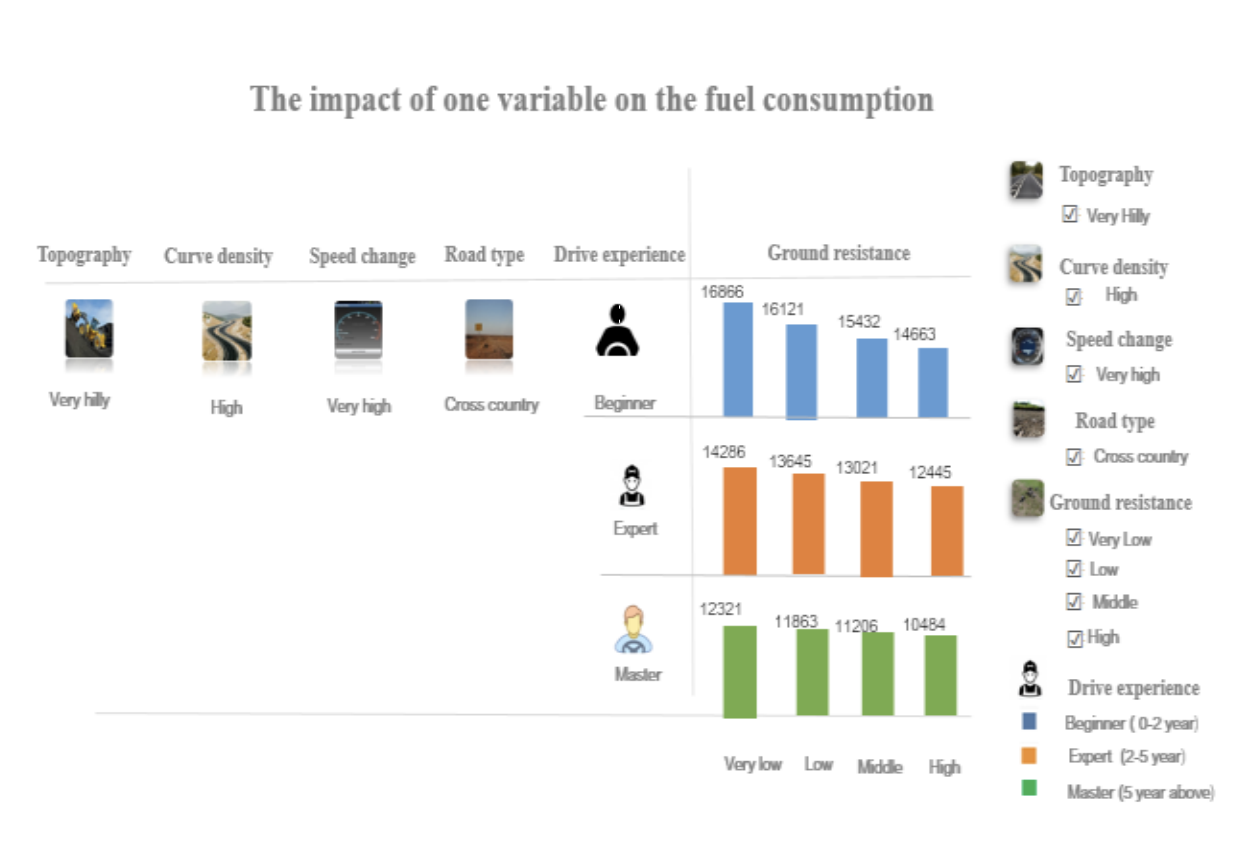

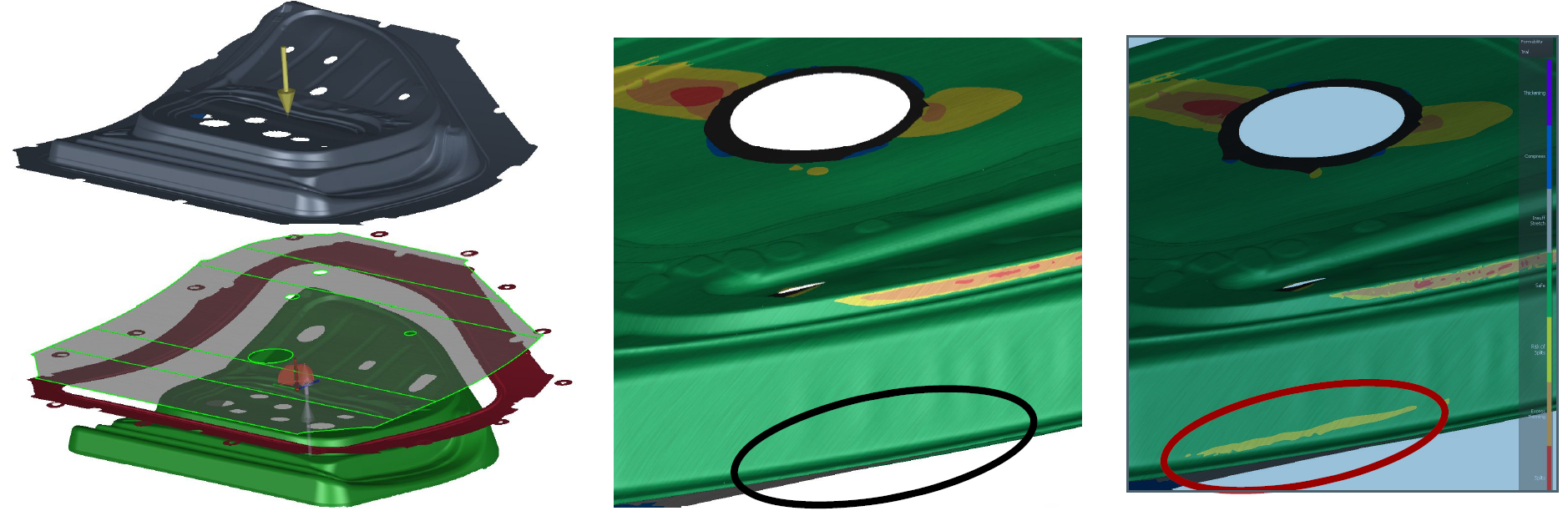

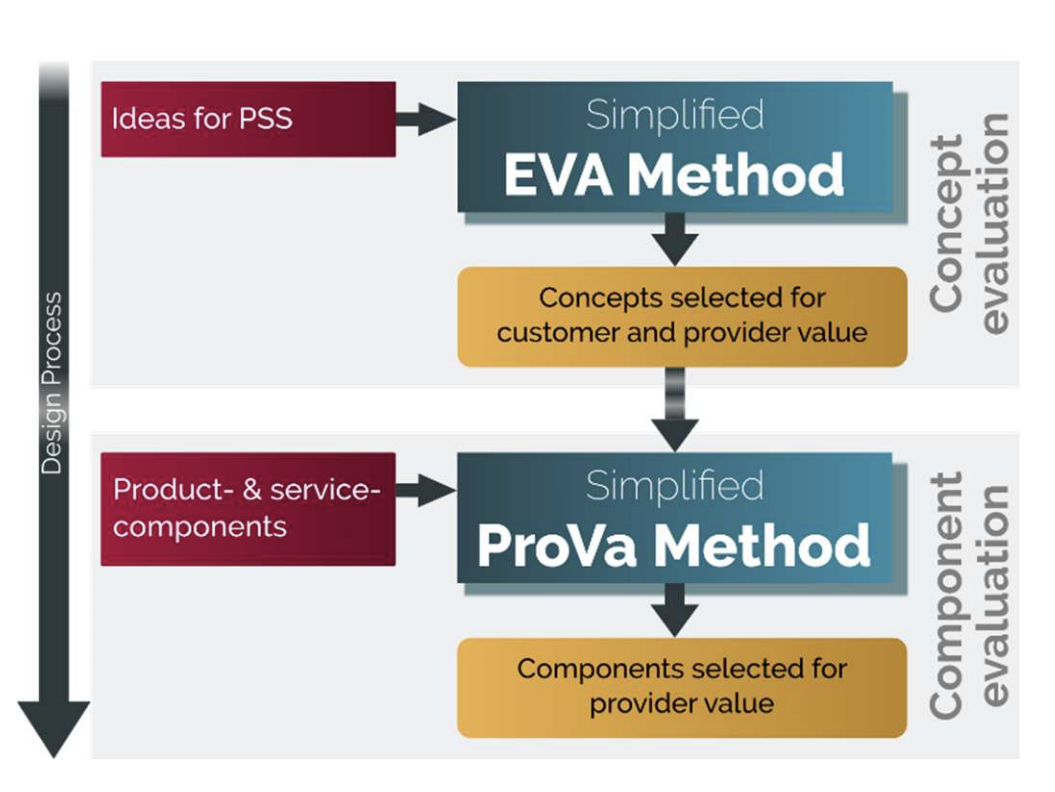

ABSTRACT Product-Service Systems, like all complex systems, are vulnerable to unpredictable environmental changes that can seriously undermine their ability to continuously deliver value to customers. The long-term consequences of volatile markets, unanticipated technologies, and unpredictable changes in society must be captured, modeled and communicated to decision makers since the earliest stages of the design, so to identify sustainable […]

Read More