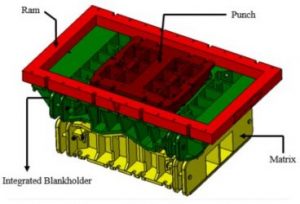

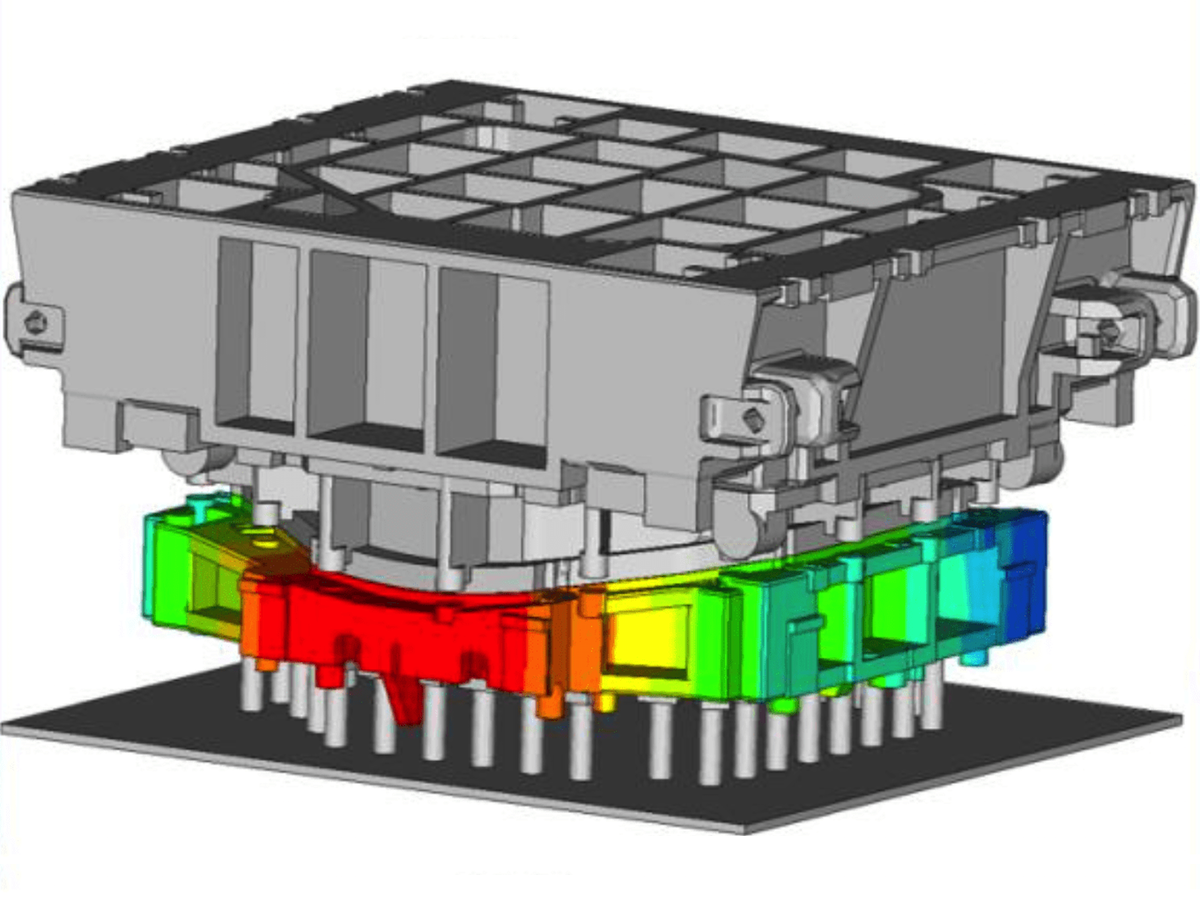

ABSTRACT Sheet metal forming in the car industry is a highly competitive area. The use of digital techniques and numerical methods are therefore of high interest for reduced costs and lead times. One method for reducing the try-out phase is virtual rework of die surfaces. The virtual rework is based on Finite Element (FE) simulations […]

Read MoreExperiments and FE-simulations of stretch flanging of DP-steels with different shear cut edge quality

- 22nd February 2018

- No Comment

ABSTRACT Dual-Phase (DP) steels are today used in the automotive industry due to its large strength to weight ratio. However, the high strength of DP-steel does have a negative impact on the general formability in sheet metal forming. Unfavourable process conditions in the press shop will, on top of this, reduce the formability of DP-steels […]

Read More