Final presentations from project course 2 (MT1539) on BTH Experience Day | 2021

- Post by: Santosh Jagtap

- 9th June 2021

- No Comment

Project course 2 (MT1539) with students from the Mechanical Engineering programme’s 3rd year delivered their final presentations as pert of BTH Experience Day 2021.

This year, mechanical engineering students worked on company-related or entrepreneurial projects that required satisfying user needs and technical functions. They worked on projects involving the design of physical artefacts with innovation potential. The students worked in teams, and collaborated with a number of stakeholders, both inside and outside of the BTH. This year, there were three teams working on a wide range of projects, such as ‘edgeless additive manufacturing ’, ‘molding re-cycled plastics’, and ‘bike powered charching kit’. The BTH makerspace and innovation lab supported students in their project work, including prototyping.

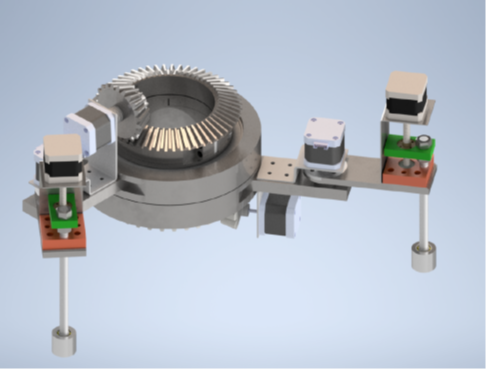

Edgeless additive manufacturing

Students: Lukas Håman, Fredrik Hjalmarsson, André Jönsson, Oscar Aydin Claesson och Jonathan Åhstedt

The company we have collaborated with – Spectrum Technology AB – manufactures furniture and other household items by large scale 3D-printing. At that scale, there are visible edges for each printed layer. Our product eliminates those edges by rolling each side, just behind the nozzle – the material comes out flattened on the sides, and eliminates the appearance of layers. “Eftersläpet” uses motors to move 360 degrees around the nozzle to ensure even distribution of force. This increases the structural integrity of the created item on top of being aesthetically pleasing to the eye.

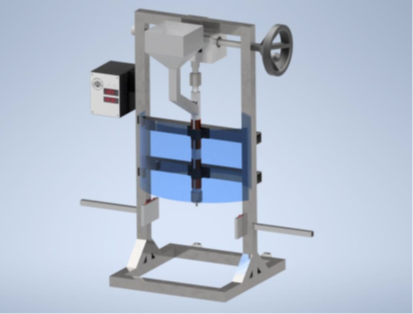

Molding recycled plastic

Students: Isak Olofsson, Jakob Nilsson, Lowe Lander, Viktor Svensson, Robin Raymundsson

The students designed a molding machine for the waste plastic from the 3D printers at BTH, the molding machine is designed so that the first-year students can build the machine at BTH. The machine will recycle the plastic into different molds.

Bike Powered Charging Kit

Students: Naret Jasim, Yasser Hajjouz, Warsame Mohamed, Mohammed Aljafari

The project created a convenient phone charging kit that suits every bike on the market. The project also includes creating a new phone-holder that is rainproof and also suits all phones on the market. Targeted customers are people who bike ride but often find the problem of running out of battery during the day. This could be people who hike and travel daily with bikes but also anyone who sometimes uses their bikes and wants to keep their phone charged during that period of time.