LighTEST – Testbeds for future production of lightweight products using smart material solutions | 2017-2020

- Post by: Tobias Larsson

- 1st April 2017

- 2 Comments

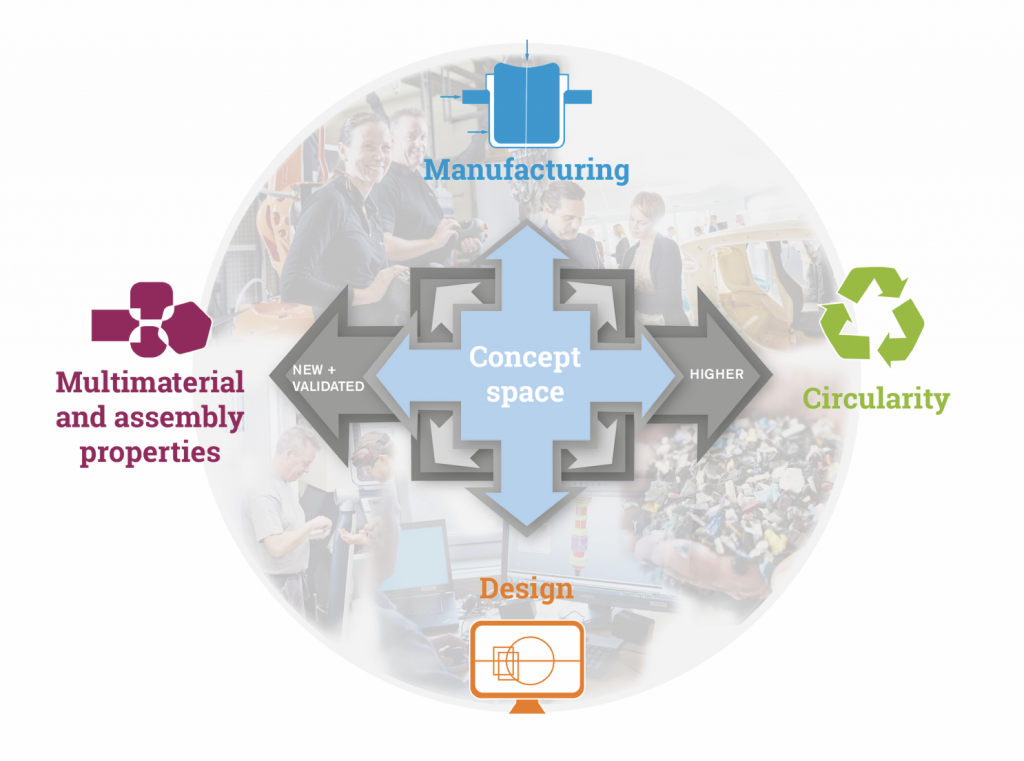

A distributed test bed will be developed for lightweight products with future demands for properties and circularity.

Three sections will be developed and linked together in a cycle:

- A test bed for rapid development, testing and characterization of advanced materials and their ability to meet customer requirements at the component and system level.

- A test bed for rapid and accurate evaluation of recycling and circularity of design, material solutions and processes.

- A test bed/pilot plant for development of production methods and technologies, also for upscaling of materials in complete solutions (at the component and system level) to medium and high volume products.

Via parallel evaluation and shared information, the ability of the Swedish value chains to develop advanced products based on advanced materials will be strengthened, with increased competitiveness as a result.

PROJECT INFORMATION

BTH project leader: Prof Tobias Larsson

Time span: 2017-2020

Funding: 34 MSEK (17 MSEK VINNOVA FFI)

Partners:

- ABB Composites

- Bergs Produktionskonsult

- Cronimet

- EBP

- Gestamp Hardtech

- PODCOMP

- Safeman

- SSAC

- GKN Aerospace

- Scania

- Volvo Cars

- TechTank Olofström

- Jernkontoret

- Kungliga Tekniska Högskolan

- Luleå tekniska universitet

- Blekinge Tekniska Högskola

- Swerea SICOMP

- Swerea IVF

RELATED LINKS

Categories: Completed projects, Research

Tagged: LighTEST, SWEREA, tobias larsson, VINNOVA

2 Comments on “LighTEST – Testbeds for future production of lightweight products using smart material solutions | 2017-2020”

Comments are closed.